Integrating the inverter into an EtherCAT® network

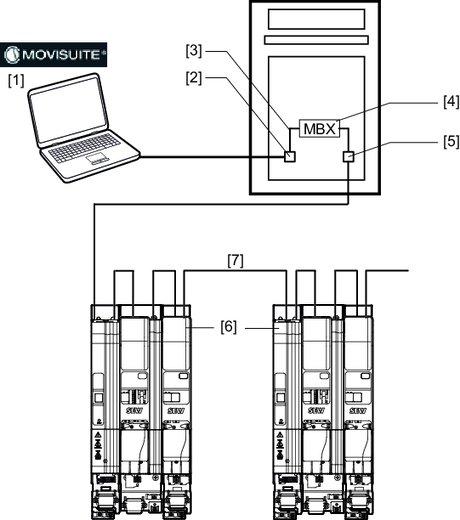

The following device topology is used in the example:

- Higher-level controller (PLC) CX2020 from Beckhoff Automation GmbH with EtherCAT® extension EK1110

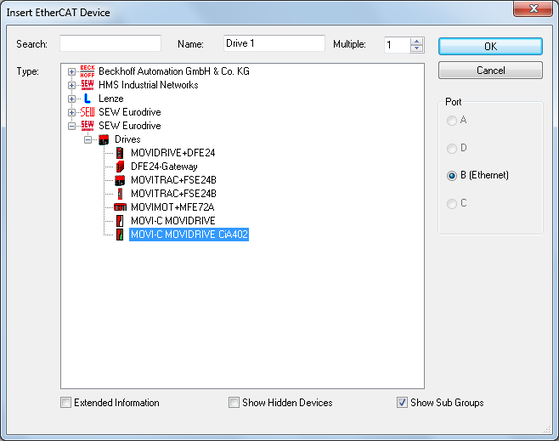

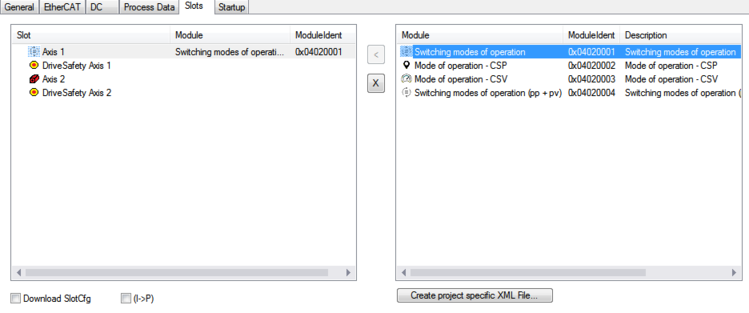

- MOVIDRIVE® modular application inverter, MDD90A double-axis module (CiA402: MDDA90ACiA402)

- MOVIDRIVE® modular application inverter, MDA90A single-axis module with MOVISAFE® CSS21A safety card (CiA402: MDA90ACiA402)

The following figure is a schematic representation of the device topology:

[1] | Engineering PC with MOVISUITE® | [5] | EtherCAT® interface of the EtherCAT® master |

[2] | Engineering interface of the EtherCAT® master | [6] | Inverter from SEW-EURODRIVE |

[3] | Internal IP routing | [7] | EtherCAT®/SBusPLUS interface of the inverters |

[4] | Mailbox gateway MBX |

|

|

For configuration and startup of the devices, the following tools are used:

- TwinCAT 3 from Beckhoff Automation GmbH for the PLC

- MOVISUITE® for inverters from SEW‑EURODRIVE

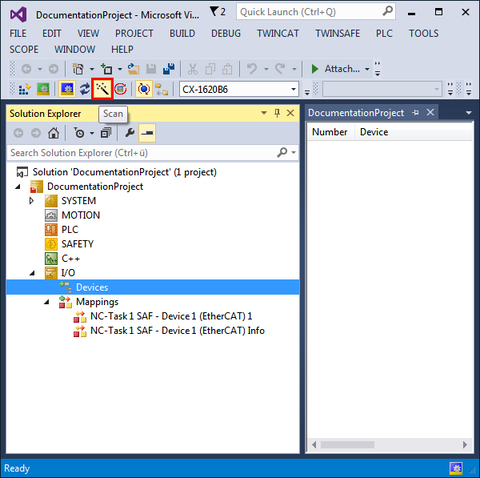

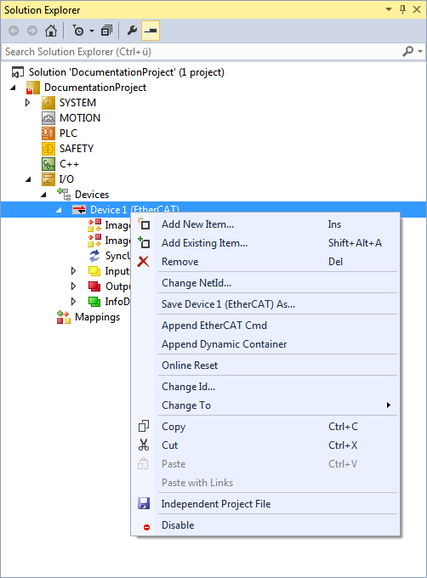

The inverter must be created in the I/O configuration of the EtherCAT® master.

Additional information

- EtherCAT®: Integrating an inverter by scanning the network

- EtherCAT®: Integrating inverters offline

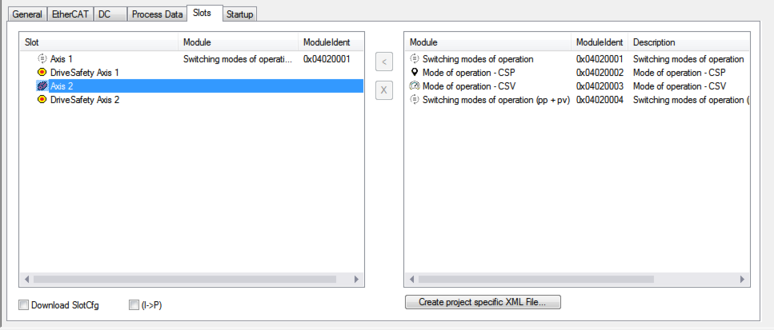

- EtherCAT®: Adjust the slot configuration, generate double-axis module

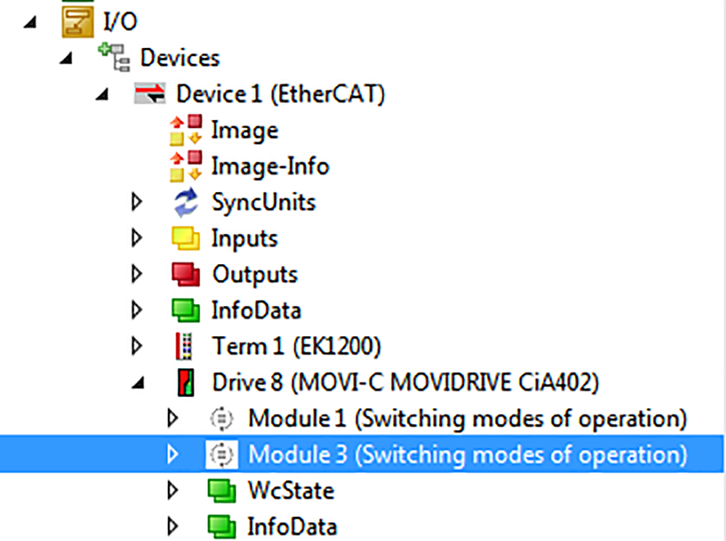

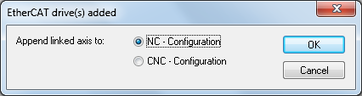

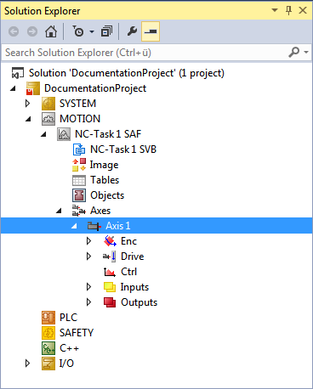

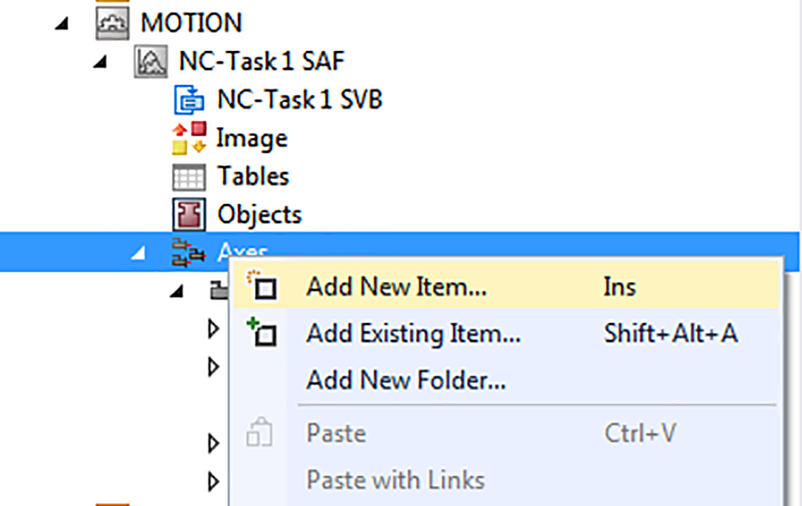

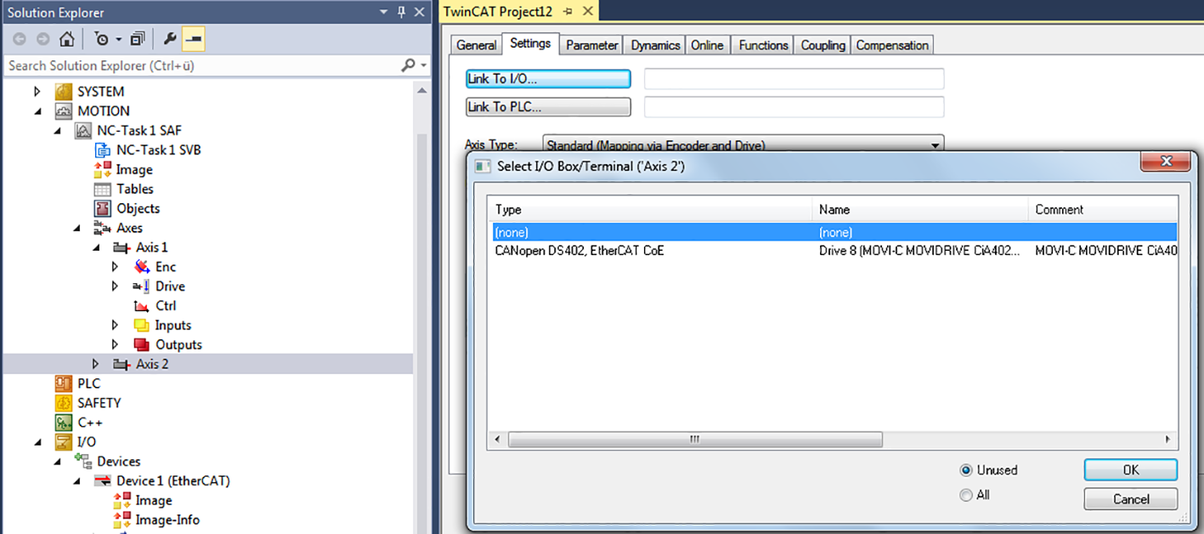

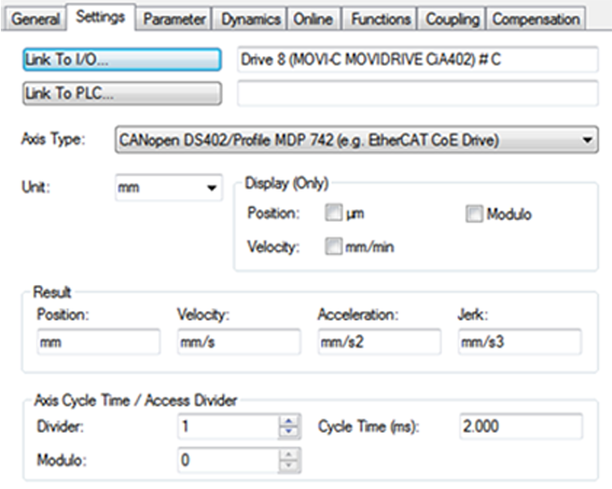

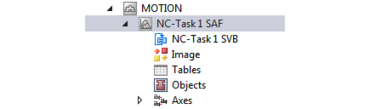

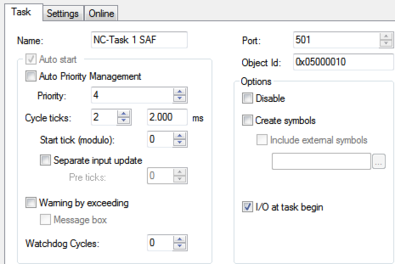

- Motion axis: Integrating inverters

- Motion Axis: Linking double-axis module

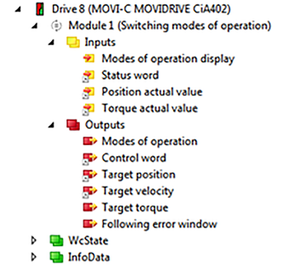

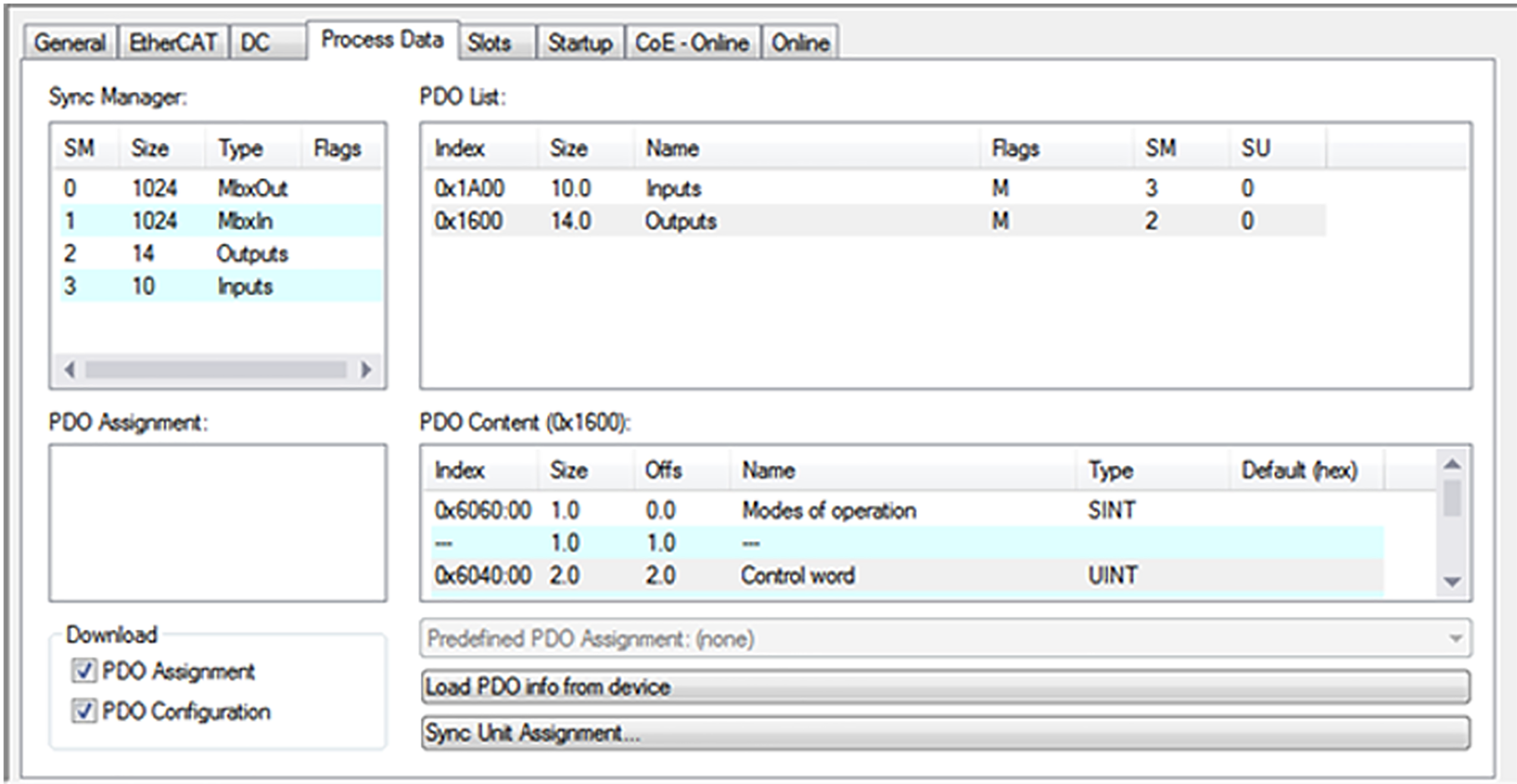

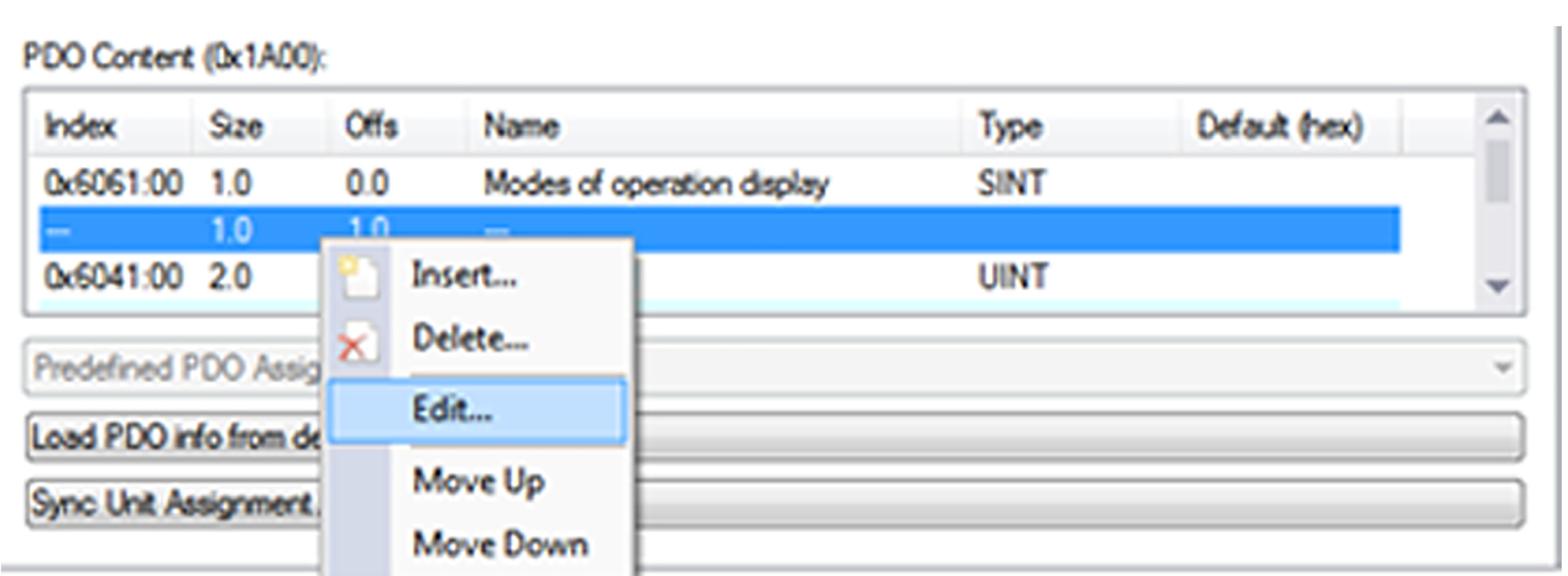

- Adapting the PDO image

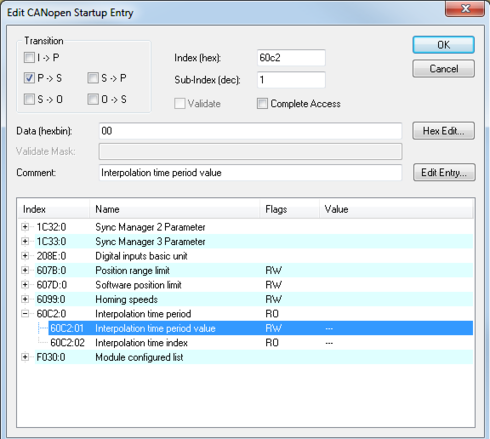

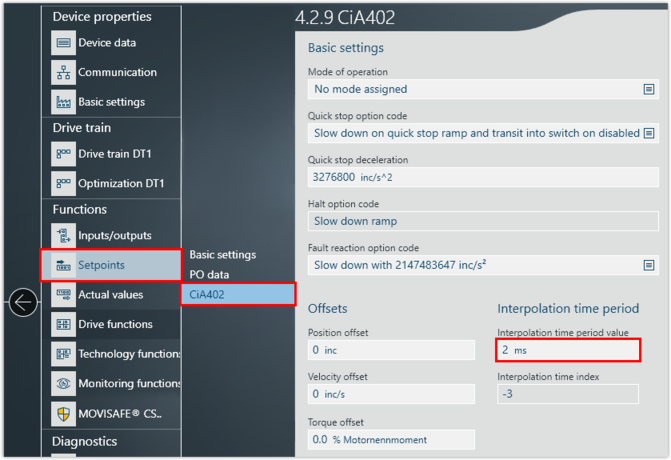

- Setting the interpolation time

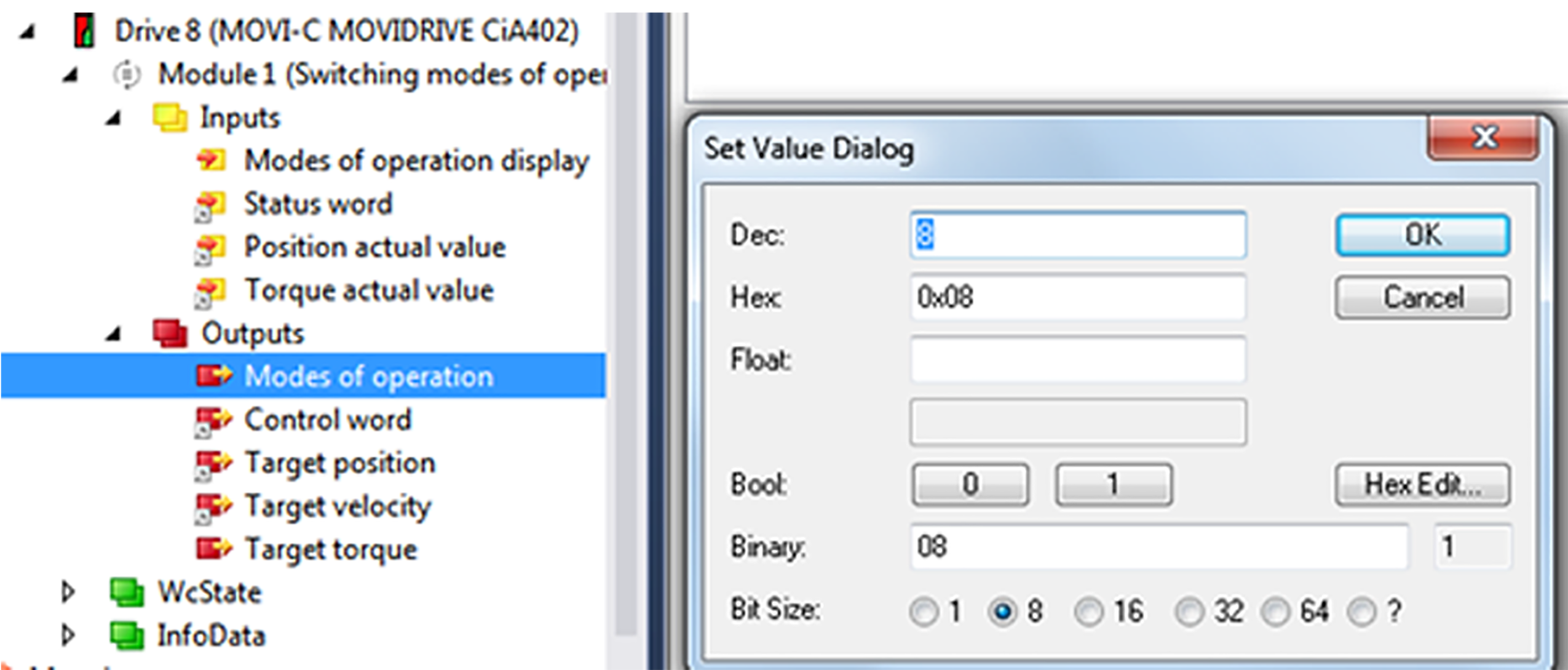

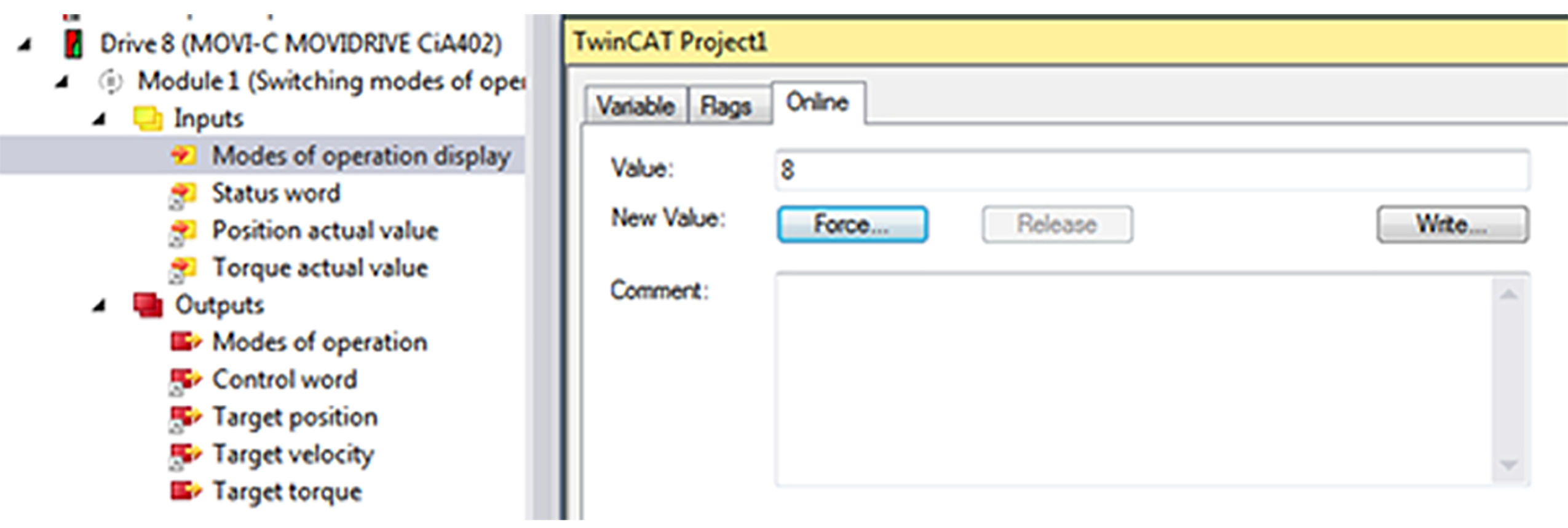

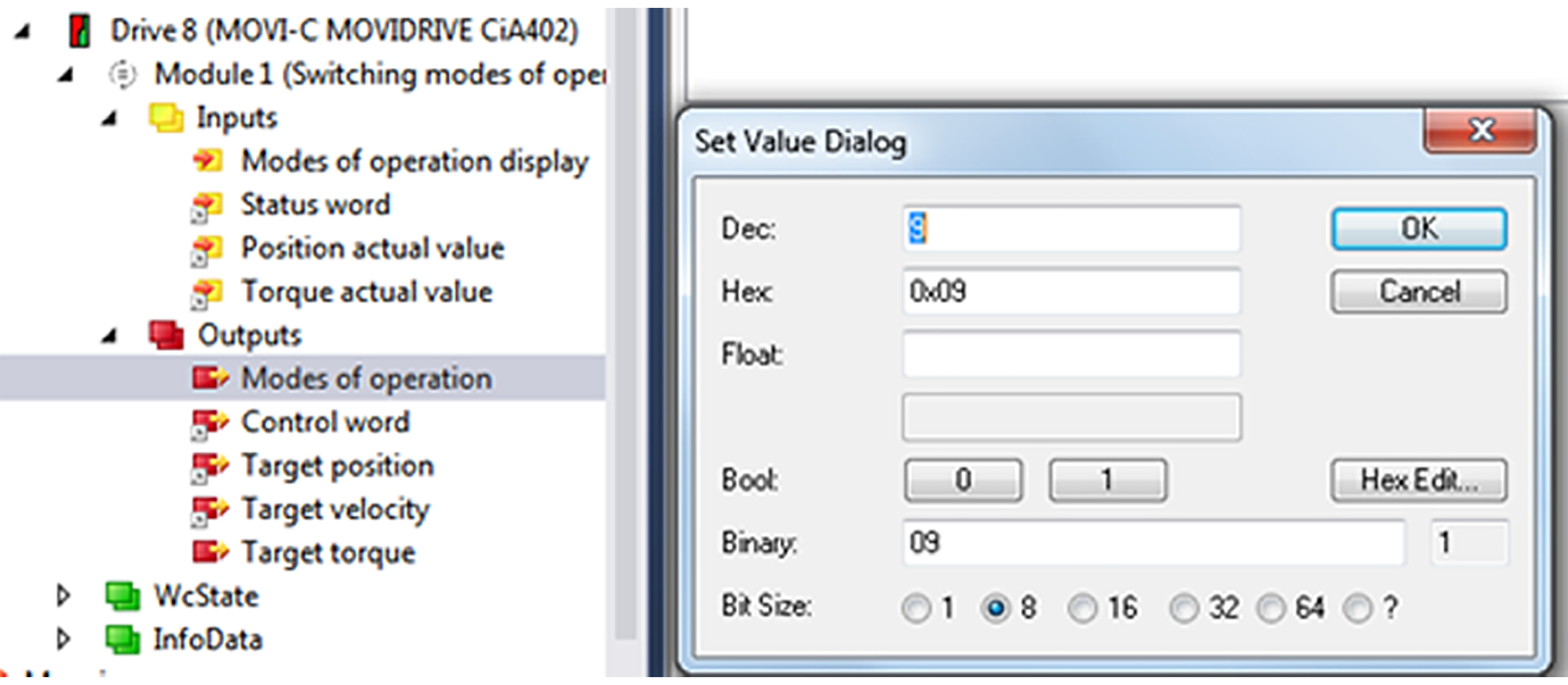

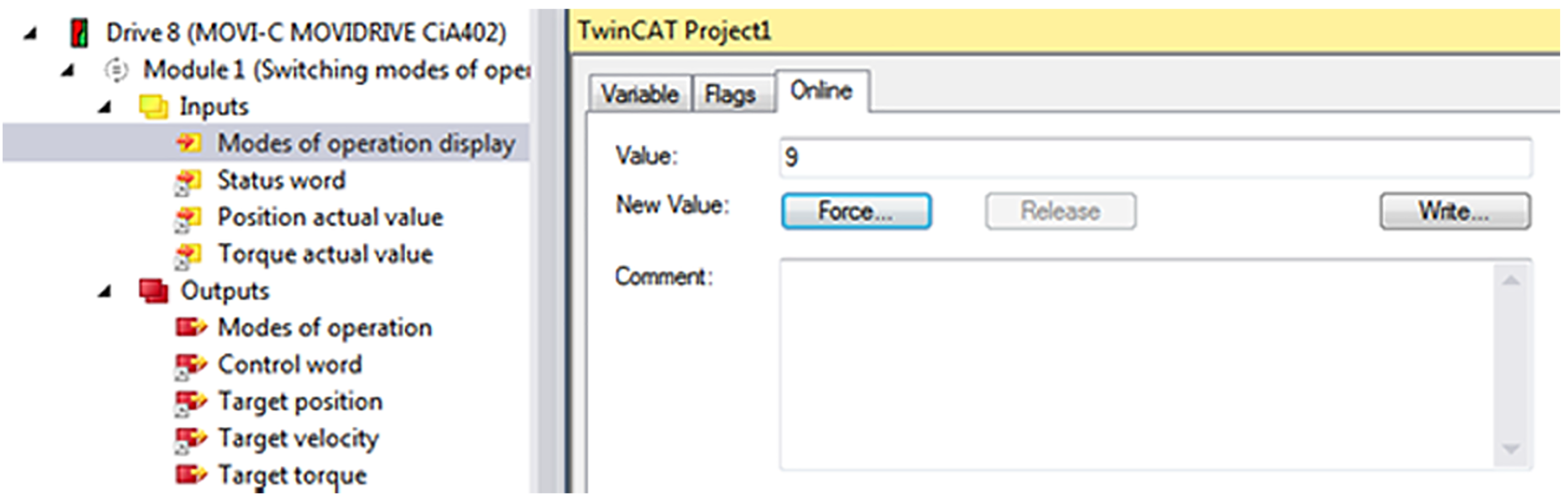

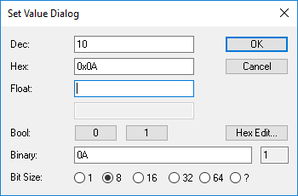

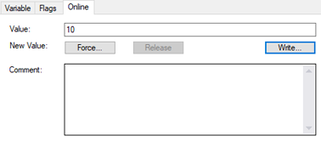

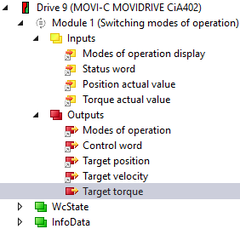

- Setting "Cyclic Synchronous Position" (csp) mode of operation

- Setting "Cyclic Synchronous Velocity" (csv) mode of operation

- Setting "Cyclic Synchronous Torque" (cst) mode of operation

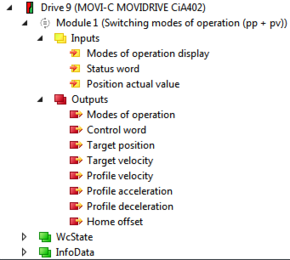

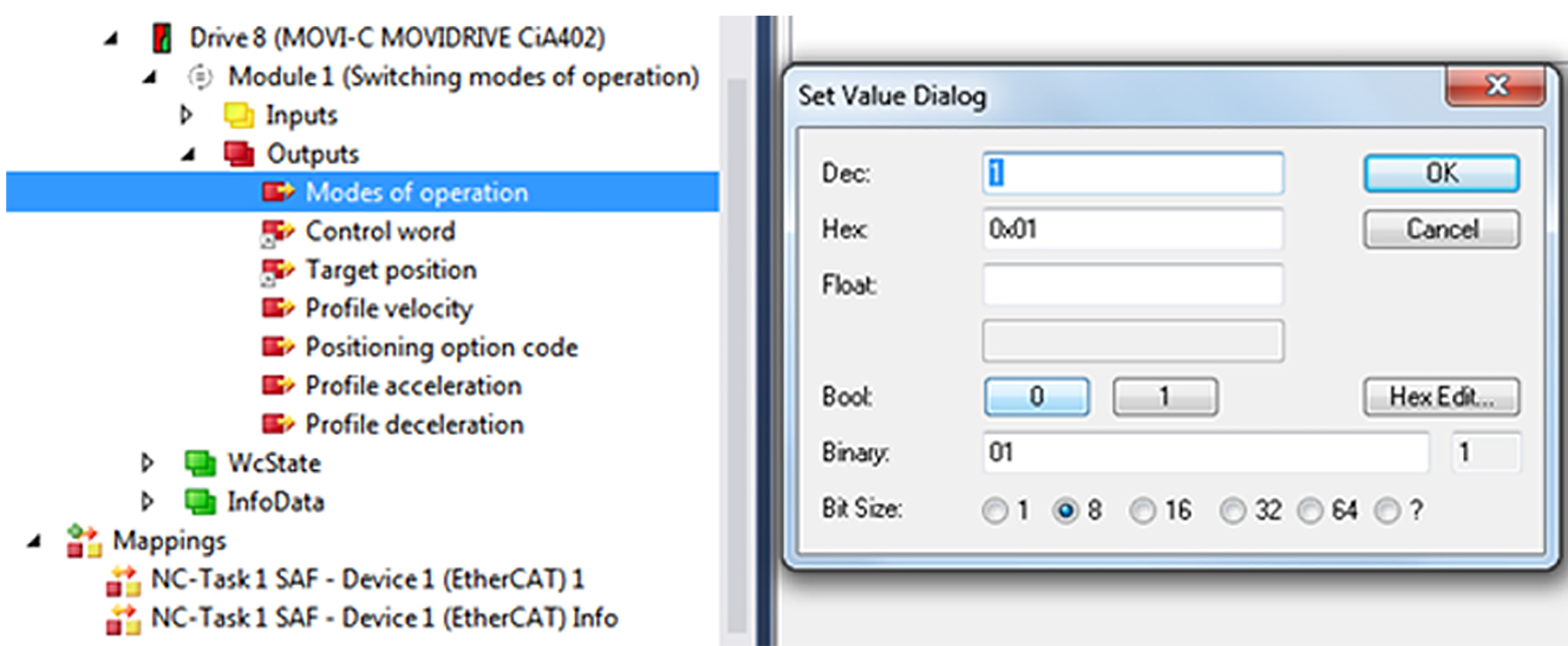

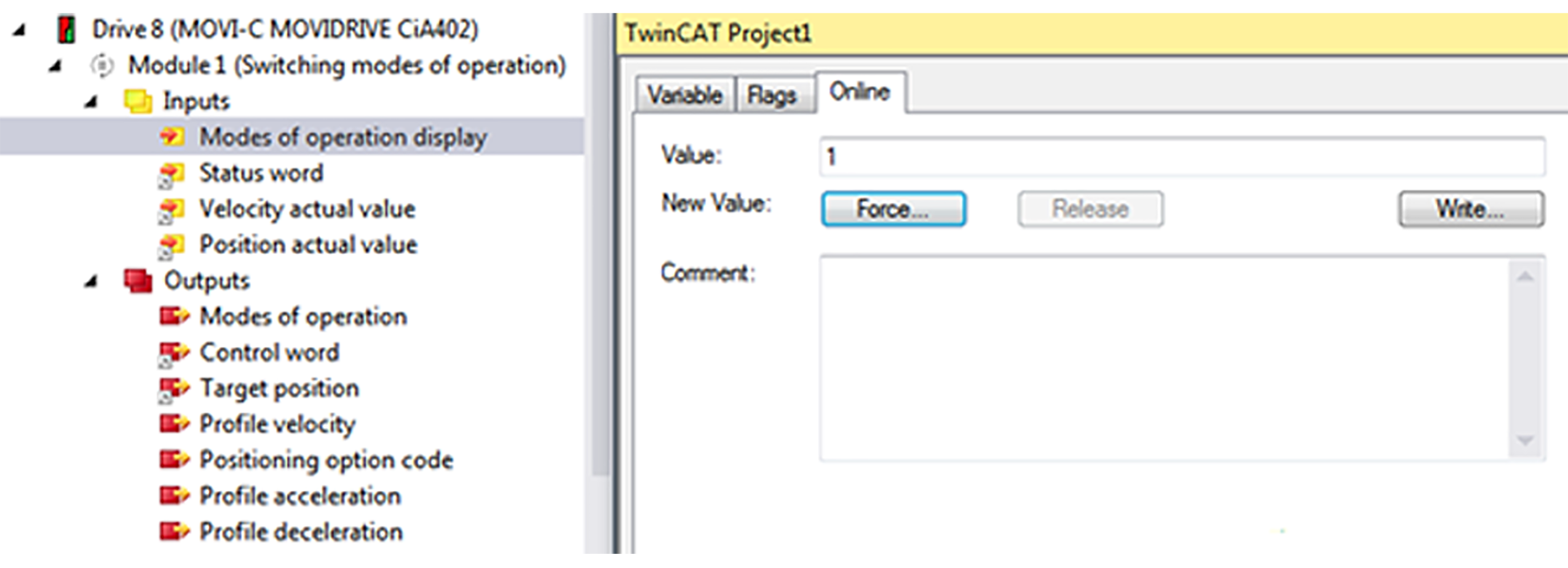

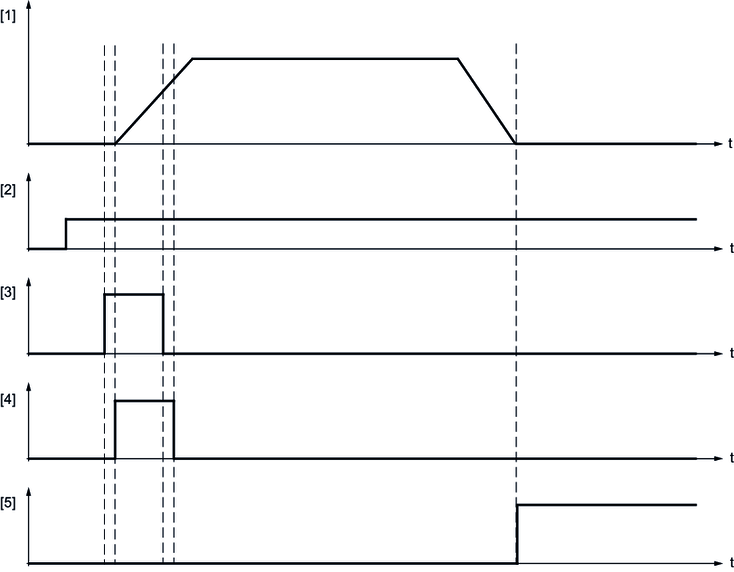

- Setting "Profile Position" (pp) mode of operation

- Setting "Profile Velocity" (pv) mode of operation

- Using "Homing" (hm) mode of operation