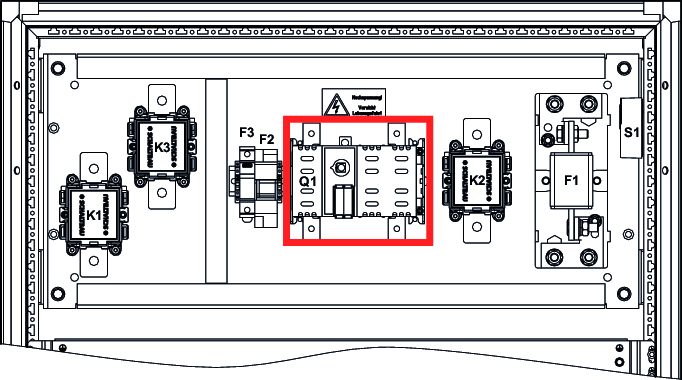

Replacing a defective Q1 disconnector

Part number | Designation | Tightening torque M8 |

|---|---|---|

29663334 | Disconnector DDC-200/2-SK | 14 Nm |

In the event of a defective Q1 disconnector, additionally check the following components for correct function:

- Auxiliary contacts Q1.1/Q1.2

- Fuse F1

- Fuse F2

- Fuse F3

- Contactor K1, K2, K3

- Storage bundle (are there defective modules in the storage bundle?)

Required tool:

- Hexagon socket: Set

- Wrench: Set

- Torque wrench 0 Nm – 20 Nm

Procedure:

- To ensure the correct installation depth of the linkage during reinstallation, mark the linkage.

- Remove the linkage by loosening the set screws.

- Loosen the M8 screws.

- Remove the auxiliary contacts.

- Remove all electrical connections.

- Remove the disconnector from the mounting plate.

- Mount the new disconnector on the mounting plate.

- Mount the auxiliary contacts.

- Restore all the electrical connections.

- Tighten the M8 screws to the specified torque.

- Mount the linkage.