Integrating the inverter into a POWERLINK network

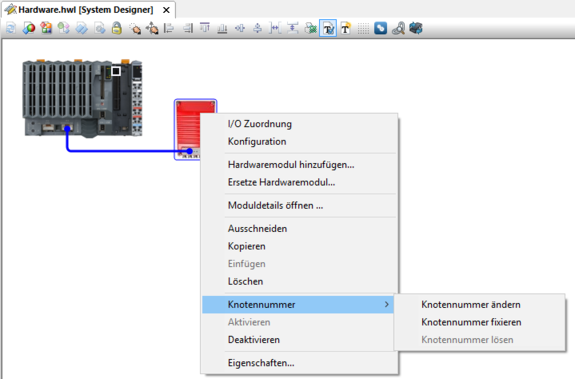

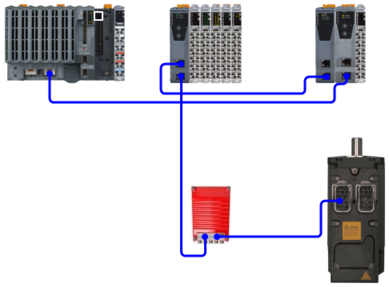

The following device topology is used in the example:

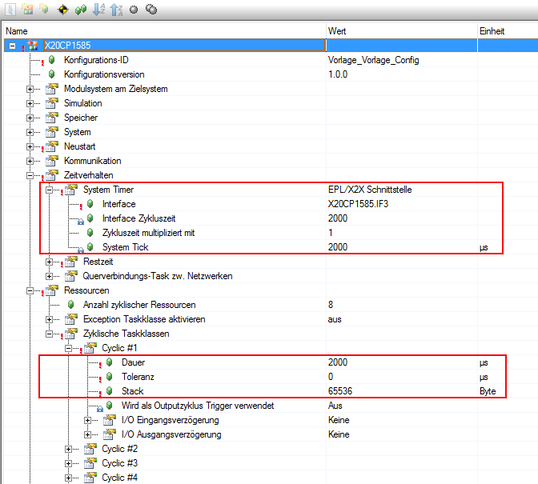

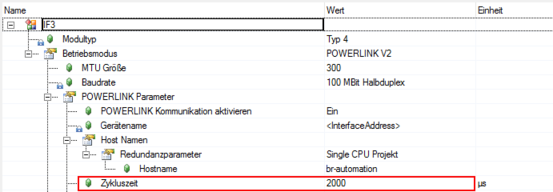

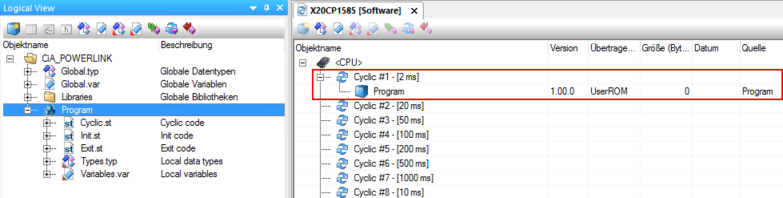

- Higher-level controller (PLC) X20CP1585 from B&R Industrial Automation GmbH

- MOVIGEAR® performance mechatronic drive unit with electronics cover DFC40A..

- USM21A interface adapter

The startup of the other inverters in the MOVI‑C® modular automation system is performed in the same way.

The following figure is a schematic representation of the device topology:

[1] | Supply voltage |

[2] | PLC |

[3] | Fieldbus connection |

[4] | MOVIGEAR® performance |

[5] | USB connection cable, type USB A‑B |

[6] | USM21A interface adapter |

[7] | Interface cable with RJ10/RJ10 connectors |

For configuration and startup of the devices, the following tools are used:

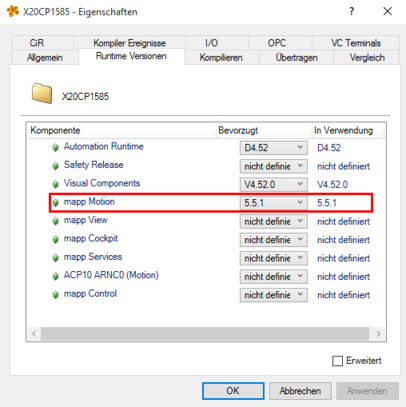

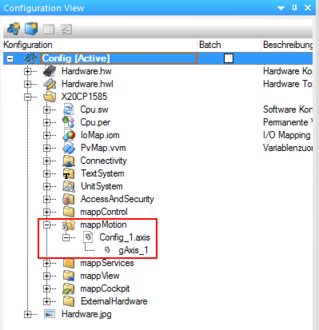

- Automation Studio from B&R Industrial Automation GmbH for the PLC

- MOVISUITE® for inverters from SEW‑EURODRIVE

Additional information

- Fieldbus stations in the sample project

- Integrating and configuring an inverter in the POWERLINK network

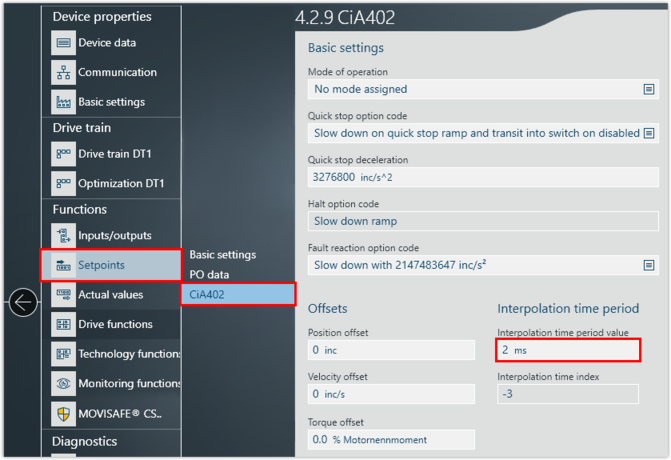

- Setting the interpolation time

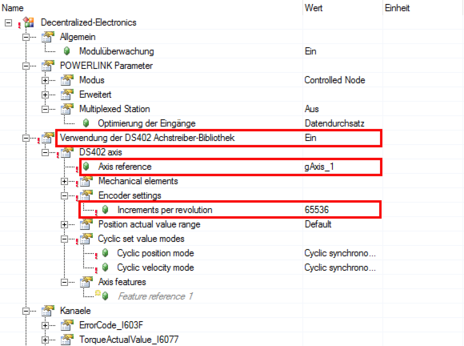

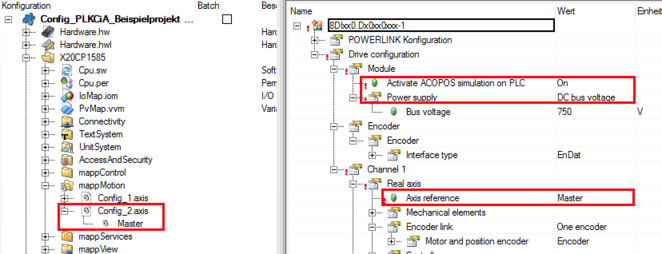

- Configuring inverter as CiA402 axis

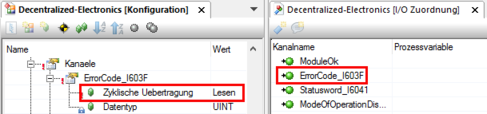

- Adapting the PDO image

- Setting "Profile Position" (pp) mode of operation

- Setting "Profile Velocity" (pv) mode of operation

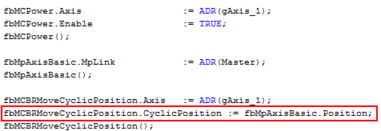

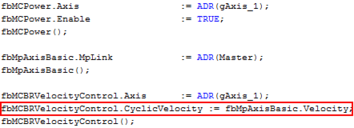

- Setting "Cyclic Synchronous Position" (csp) and "Cyclic Synchronous Velocity" (csv) mode of operation

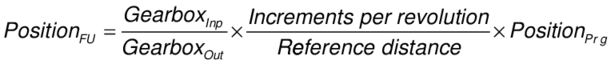

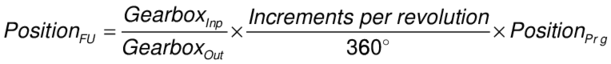

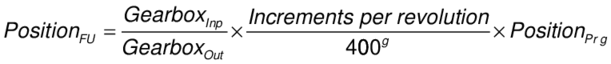

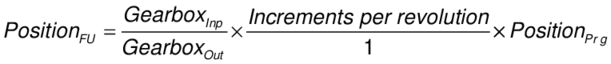

- Setting scaling