Reverse mode (602)

Rapid/creep speed positioning starts in the direction selected via the control word. Unlike the "Feed-in" operating mode (600), the direction of rotation must be changed when the stop sensor has been reached. After changing the direction in "reverse mode" (602), the motor starts without a rising edge of the start bit in the selected direction of movement.

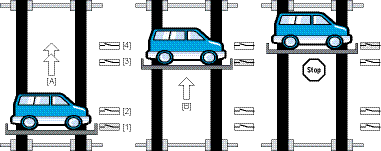

The following figure shows a typical use case of the reverse mode for a lifting station.

In reverse mode, positioning follows the same principle as when feeding in. After positioning in one direction, however, further feeding in in the same direction is not possible. The "In position" message blocks the start of another feed-in process in the same direction. The blocking prevents the material to be conveyed from unintentionally moving to the mechanical stop.

DANGER

Risk of crushing due to falling load.

Severe or fatal injuries.

- Do not stand under the load.

- Secure the hazard zone.

[1] | Sensor "stop CCW" | [A] | Rapid movement |

[2] | Sensor "F/SF/S = Rapid/creep speed | [B] | Slow movement |

[3] | Sensor "F/S1) CW" | ||

[4] | Sensor "stop CW" |

Functional description

Functional description | |

|---|---|

Mode selection | Mode 602 |

Prerequisite | The drive is enabled. |

Functional | At the positive edge of the start bit, the drive accelerates along the set acceleration ramp until it reaches rapid speed. Upon tripping of the "rapid/creep speed" sensor, the drive brakes along the set deceleration ramp until it reaches creep speed. After the "Stop" sensor trips, the drive brakes along the set stop ramp to a standstill. Repeated starting in the same direction is blocked. |