Physics (MOVIKIT® Robotics)

INFORMATION

Only visible with kinematic models that support physics simulation. Every kinematic model indicates whether it supports physics simulation. For further information, refer to chapter Physics simulation. Axis-joint transformation is not supported.

INFORMATION

For each joint axis, an axis with MOVIKIT® MultiMotion and activated "Physics simulation" must be inserted below the "Robotics" software node. For drive project planning, a virtual axis is recommended as a device.

Parameter group | Description |

|---|---|

Basic settings | |

Activate export to SEW-Workbench | Adds the export function for the SEW-Workbench to the IEC project. To use the function taking account of an additional transmission or a rotary to linear gear ratio, the "Activate export to SEW-Workbench" function must be activated for MOVIKIT® MultiMotion. |

Activate collision response | Activates the "Collision response" function (add to the IEC project). You can find more information on the operating principle and startup in chapter Collision detection (CollisionDetection). INFORMATION: To use the function, the "Collision detection" function must be activated for at least one lower-level MultiMotion axis. See Physics (MOVIKIT® MultiMotion). |

Collision response | |

Collision response

INFORMATION: Visible only if "Activate collision response" is activated. | Collision response that is to be triggered after detecting a collision. See chapter Collision detection (CollisionDetection). – Information – Warning – Application stop without output stage inhibit – Application stop + output stage inhibit – True-to-path emergency stop + output stage inhibit – Axis-wise emergency stop + output stage inhibit |

When physics simulation is activated, the following submenus with specific setting options are displayed depending on the selected kinematic model:

The following inertia properties must be defined for all arm sections of the selected kinematic model.

INFORMATION

For the TRIPOD_RRR_M10/TRIPOD_RRRR_M10/TRIPOD_RRRRR_M10, all three upper arms and all six forearms must each have identical masses, centers of gravity and inertias. The "Copy arm properties" button makes it easier to set the parameters correctly.

Parameter name | Description |

|---|---|

[Kinematic model] – inertia properties | |

Mass | Mass of the arm section. |

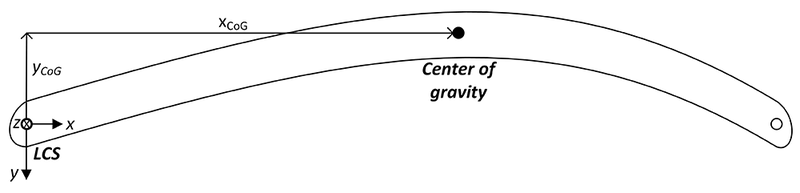

Center of gravity (X, Y, Z) | Center of gravity of the arm section. X, Y and Z refer to the LCS (Link Coordinate System) of the arm section. |

Inertia (XX, YY, ZZ, XY, XZ, ZX) | Inertia matrix around the center of gravity. X, Y and Z refer to the LCS (Link Coordinate System) of the arm section. |

The origin of the LCS (Link Coordinate System) of each arm section is at the beginning of the arm section in the joint (see figure). The Z-axis points in positive axis direction. The X-direction usually points to the next joint.

The LCS of all kinematic models are shown in chapter Functional description for the respective kinematic model and can also be displayed in the 3D simulation.

Special features and specific configuration parameters are also available for the following kinematic models.

Parameter name | Description |

|---|---|

ROLLER GANTRY: General settings | |

Manual setting of the initial belt tension |

|

Initial belt tension | Initial belt tension. Only effective if manual setting of the initial belt tension is activated. |

ROLLER_GANTRY_RR_M10: Inertia properties | |

Belt pulleys: Inertia | Mass moment of inertia of all belt pulleys together |

Belt: Inertia | Mass moment of inertia of the belt Can be calculated from |

1st Cartesian link: Mass | Mass of the first Cartesian joint that can only be moved in one direction:

|

2nd Cartesian link: Mass | Mass of the second Cartesian joint that can be moved in two directions:

|

The robot can be loaded with a workpiece at the TCP during runtime. For consideration in the physics simulation, the inertia properties can be configured in the "Workpiece settings" submenu.

If telescopic shafts have been activated in the settings of the kinematic model for TRIPOD_RRR_M10/ TRIPOD_RRRR_M10/ TRIPOD_RRRR_M10, the inertia properties (mass, center of gravity (X, Y, Z) and inertia (XX, YY, ZZ, XY, XZ, YZ)) of the two telescopic shaft parts, as well as the friction between the telescopic shaft parts, must also be parameterized. These properties are parameterized in the submenus that are displayed when telescopic shafts have been activated in the "Simulation" submenu of the kinematic model. If no friction values are known, the friction during operation can be determined as described in the chapter Putting the physics simulation into operation in MOVIKIT® MultiMotion. INFORMATION: Simulating the drive torques for the rotary drive around A is currently not possible.

Parameter name | Description |

|---|---|

Workpiece settings | |

Mass | Mass of the workpiece |

Center of gravity (X, Y, Z) | Center of gravity of the workpiece. X, Y and Z refer to the TCS (Tool Coordinate System) of the robot. |

Inertia | Inertia matrix around the center of gravity. X, Y and Z refer to the TCS (Tool Coordinate System) of the robot. |