Selection of the MOVIONE® drive unit

Observe the following procedure when selecting the MOVIONE® drive unit:

- Selection of a suitable gear unit size

(Specification: Helical-bevel gear unit) - Requirement: The maximum output torque of the gear unit must be greater than the maximum required application torque: Ma max ≥ Mmax.

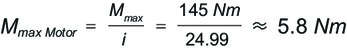

- On the basis of the application calculations and taking account of the efficiency, the maximum application torque during startup (first travel section) is Mmax = 145 Nm.

- Result: Helical-bevel gear units of size K.37 meet this requirement.

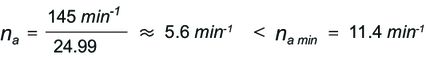

- Selecting the gear ratio with suitable output speed:

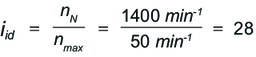

- Requirement: The application calculations result in a maximum required output speed of nmax = 50 min-1.

- To achieve a high setting range and an optimum efficiency, the required output speed should be achieved as precisely as possible at an input speed of ne = nN = 1400 min-1 (nominal motor speed with star connection).

- Result: As there is no ideal gear ratio

for the selected gear unit, the next smaller gear ratio available i = 24.99 is selected. - There are no external overhung loads acting on the gear shaft in this example.

- Selecting a suitable motor:

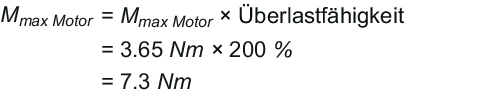

- Requirement: Select a motor/inverter combination that can provide at least

at peak performance.

at peak performance. - Result: Select the DRN80MK4 motor with the assigned inverter from the following table (from chapter "Technical data").

MOVIONE® drive unit | DRN.. | |||||||

|---|---|---|---|---|---|---|---|---|

71MS4 | 71M4 | 80MK4 | 80M4 | 90S4 | 90L4 | |||

Inverter | ..0040.. | |||||||

Inverter nominal output current | 0.72 A | 1.02 A | 1.29 A | 1.75 A | 2.55 A | 3.4 A | ||

Nominal power | PN | 0.25 kW | 0.37 kW | 0.55 kW | 0.75 kW | 1.1 kW | 1.5 kW | |

Nominal torque | MN | 1.7 Nm | 2.5 Nm | 3.65 Nm | 4.95 Nm | 7.2 Nm | 9.8 Nm | |

Overload capacity of MN |

| 200% | ||||||

- Checking further topics:

- Feasibility of the selected motor/gear unit combination

- Service factor

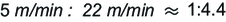

- Checking the setting range:

- Setting range of the application

- This means the standard setting range of 1:10 (star connection) is sufficient.

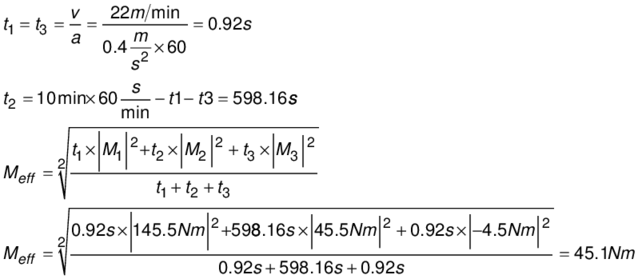

- Thermal check of the MOVIONE® drive unit

- Requirement: In order to avoid thermal problems, the effective torque requirement of the application must be smaller than the continuous output torque of the drive unit.

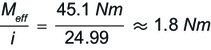

- The effective torque requirement (including the efficiency of the application) is 45.1 Nm, which corresponds to a torque requirement of

at the motor shaft.

at the motor shaft. - The selected motor/inverter combination DRN80MK4 with the assigned inverter has a nominal torque of 3.65 Nm.

- Result: The requirements are met.

MOVIONE® drive unit | DRN.. | |||||||

|---|---|---|---|---|---|---|---|---|

71MS4 | 71M4 | 80MK4 | 80M4 | 90S4 | 90L4 | |||

Inverter | ..0040.. | |||||||

Inverter nominal output current | 0.72 A | 1.02 A | 1.29 A | 1.75 A | 2.55 A | 3.4 A | ||

Nominal power | PN | 0.25 kW | 0.37 kW | 0.55 kW | 0.75 kW | 1.1 kW | 1.5 kW | |

Nominal torque | MN | 1.7 Nm | 2.5 Nm | 3.65 Nm | 4.95 Nm | 7.2 Nm | 9.8 Nm | |

Overload capacity of MN |

| 200% | ||||||

- Checking further topics:

- Derating due to increased ambient temperature

- Derating due to installation altitude