Torque control (800)

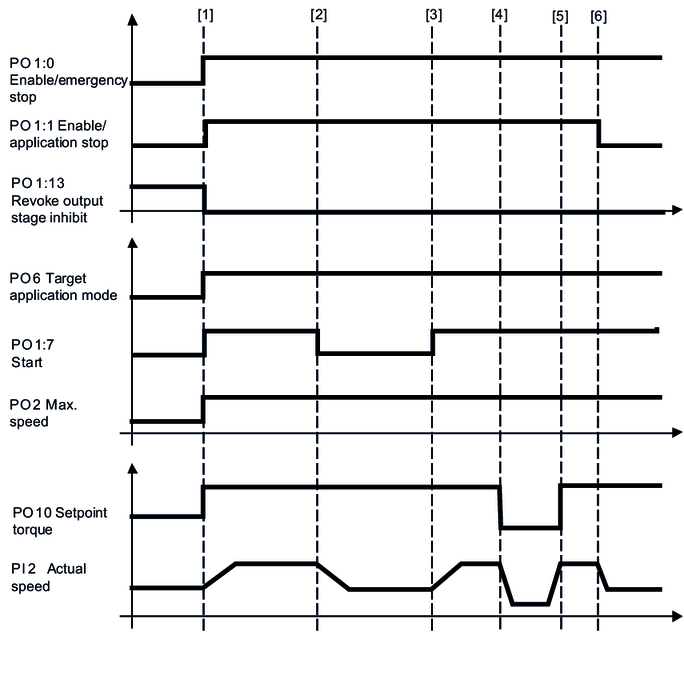

Torque-controlled movement (800) of an axis with or without encoder feedback in FCB 07 torque control drive function. The sign of the torque setpoint defines the direction of motor rotation: A positive setpoint corresponds to a positive direction of motor rotation.

The maximum speed is specified by the process data word "PO 2: Setpoint speed/maximum speed".

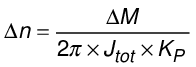

- When the motor reaches the maximum speed, the torque is limited regardless of the setpoint torque. The deceleration and acceleration are determined by the setpoint torque and the applied load torque.

- If the value is 0, the motor is stopped with the "Torque" application limit. No deceleration ramp is used.

The operating mode can be activated in the following control modes:

- CFC

- VFCPLUS – with and without encoder

- ELSM – without encoder, above the transition speed (2 – 5% of the nominal speed) in the "controlled operation” operating range

- The FCB 07 torque control drive function can only be activated when the flying start function is active and above the transition speed (example: winding drive). If the speed is too low, the system shuts down with an error message. The transition speed can be achieved either by an external drive or by speed control of the inverter in the FCB 05 speed control drive function.

INFORMATION

In torque control operating mode (800), the speed controller must be set expediently via the drive train optimization.

Use hardware limit switches to monitor the travel range.

INFORMATION

Monitoring of the software limit switches is deactivated in operation without an encoder.

Use hardware limit switches to monitor the travel range.

INFORMATION

In torque control operating mode (800), the "Torque" application limit is always effective in the stop FCBs regardless of the setting of the "Use torque limits from profile value connection" parameter.

Additional information