Safe Torque Off function

INFORMATION

The deactivated STO function does not prevent the inverter from restarting unintentionally. An automatic restart may occur as soon as the STO inputs obtain a valid "high" signal (depending on the parameter settings). For this reason, do not use this deactivated STO function to carry out brief non-electrical work (for example, cleaning or maintenance).

The STO function integrated into the inverter meets the definition of "Safe Torque Off" in accordance with IEC 61800-5-2:2016.

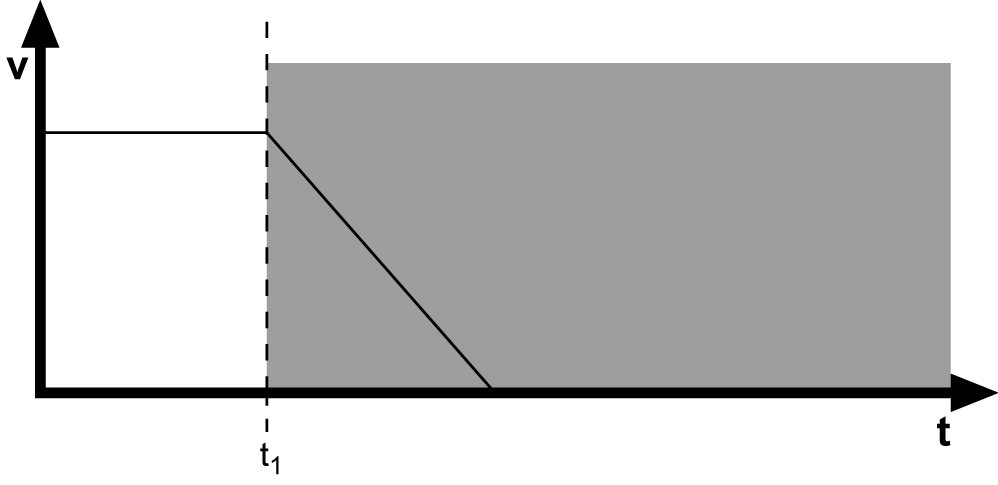

The STO function corresponds to an uncontrolled stop in accordance with category 0 (emergency off) of IEC 60204-1. If the STO function is activated, the motor coasts to a stop. This stop procedure must be in accordance with the system that drives the motor.

The inverter is tested in accordance with the safety standards specified below:

SIL Safety integrity level | PFHD Probability of dangerous failure per h | SFF Safe failure fraction | Service life | |

|---|---|---|---|---|

EN 61800‑5‑2 | 2 | 1.23 × 10-9 1/h (0.12% of SIL 2) | 50% | 20 years |

PL Performance level | CCF (%) Common cause failure | |

|---|---|---|

EN ISO 13849‑1 | PL d | 1 |

SILCL | |

|---|---|

EN 62061 | SILCL 2 |

Information: The above values are not achieved if the inverter is installed in an environment whose limit values lie outside the values specified in chapter Ambient conditions.

INFORMATION