Non-safety rated enable control

To implement non-safety rated enable control, assign the required enable type to the variables listed below in SEW_GVL_internal.

Application examples:

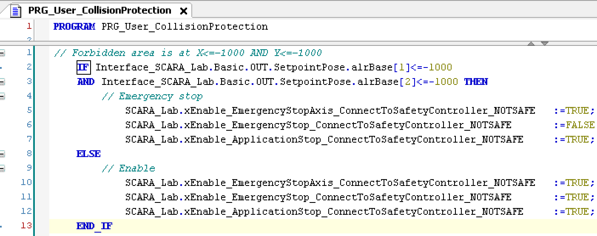

- Connection of the signal of a safety controller to the MOVI-C® CONTROLLER for path-controlled stopping of the robot before activation of STO, by the safety controller on the MOVIDRIVE® generation C inverter.

- Application hardware limit switches on a ROLLER GANTRY

- Applicative work envelope or collision monitoring system

The advantage of these variables over the enable signals in the control signal sources (SEW_GVL user interface, RobotMonitor, fieldbus interface) is that they are always effective regardless of the control signal source with access rights. So if at least one of the following three signals is not "TRUE", a stop is triggered regardless of the enable signals in the control signal sources ("MyRobot" corresponds to the robot node name defined by the user in MOVISUITE®).

MyRobot.

xEnable_EmergencyStopAxis_ConnectToSafetyController_NOTSAFE :=

xApplicativeEnable_EmergencyStopAxis;

MyRobot.

xEnable_EmergencyStop_ConnectToSafetyController_NOTSAFE :=

xApplicativeEnable_EmergencyStop;

MyRobot.

xEnable_ApplicationStop_ConnectToSafetyController_NOTSAFE :=

xApplicativeEnable_ApplicationStop;

The highest priority is given to resetting the

xEnable_EmergencyStopAxis_ConnectToSafetyController_NOTSAFE signal to "FALSE", followed by

xEnable_EmergencyStop_ConnectToSafetyController_NOTSAFE.

Removing the enable in the control signal sources has an additional effect.