Configuration

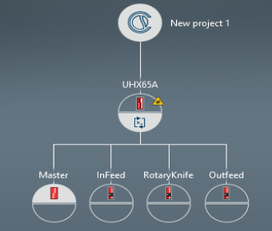

- For the following application example, a MOVI-C® CONTROLLER is required as hardware. The real axes used are simulated.

- In MOVISUITE® in "Planning" mode, create a project with a MOVI-C® CONTROLLER, one virtual ("master") and three real axes ("InFeed", "RotaryKnife", "OutFeed"). In the application example, the virtual axis acts as the master axis.

- Configure a valid drive train without user units for the real axes.

- Assign the following software modules to the axes:

- Master: MOVIKIT® Gearing

- InFeed: MOVIKIT® FilmFeeder

- RotaryKnife: MOVIKIT® RotaryKnife

- OutFeed: MOVIKIT® Gearing

- Configure the user unit for the "master" axis:

- User unit: User-defined unit: Cycle

- Position: Cycle, number of decimal places: 6

- Speed: Cycle/min, number of decimal places: 4

- Acceleration: Cycle/(min*s), number of decimal places: 2

- Configure the cycle limit for the "master" axis.

- Modulo minimum: 0 cycles

- Modulo maximum: 1 cycle

- Configure the user unit for the "InFeed" axis:

- User unit: User-defined unit: mm

- 1 revolution = 100 mm

- Position: mm, number of decimal places: 3

- Speed: mm/s, number of decimal places: 4

- Acceleration: mm/(s*s), number of decimal places: 2

- Configure the user unit for the "RotaryKnife" axis:

- User unit: Degree

- Position: Degrees, number of decimal places: 3

- Speed: Degrees/s, number of decimal places: 4

- Acceleration: Degree/(s*s), number of decimal places: 2

- Check the configuration of the following cycle limit for the "RotaryKnife" axis.

- Modulo minimum: 0 degrees

- Modulo maximum: 360 degrees

- Configure the user unit for the "OutFeed" axis:

- User unit: User-defined unit: mm

- 1 revolution = 100 mm

- Position: mm, number of decimal places: 3

- Speed: mm/s, number of decimal places: 4

- Acceleration: mm/(s*s), number of decimal places: 2

- Configure the software module of the "master" axis:

- Fieldbus interface – Activate fieldbus connection

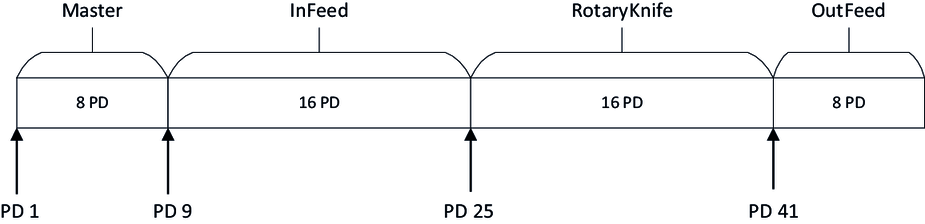

- Fieldbus interface – Start address: 1

- Configure the software module of the "InFeed" axis:

- Basic settings – Activate simulation

- Synchronous operation – Master source: Configured axis

- Synchronous operation – Name of master axis: Master

- Fieldbus interface – Activate fieldbus connection

- Fieldbus interface – Start address: 9

- Configure the software module of the "RotaryKnife" axis:

- Basic settings – Activate simulation

- Electronic cam – Master source: Configured axis

- Electronic cam – Name of master axis: Master

- Rotary knife – Type of master axis: Modulo axis – Cyclic position

- Fieldbus interface – Activate fieldbus connection

- Fieldbus interface – Start address: 25

- Configure the software module of the "OutFeed" axis:

- Basic settings – Activate simulation

- Synchronous operation – Master source: Configured axis

- Synchronous operation – Gear ratio master/slave numerator: 160 mm

- Synchronous operation – Gear ratio master/slave denominator: 1 cycle

- Synchronous operation – Name of master axis: Master

- Fieldbus interface – Activate fieldbus connection

- Fieldbus interface – Start address: 41

- The configuration results in the following process data assignment:

- Switch to "Startup" mode.

- Connect the MOVI-C® CONTROLLER in the project view with the MOVI-C® CONTROLLER in the network view, and then update the IEC project.