Performing a wobble measurement (only for the safety encoder design)

Fault exclusion of the mechanical motor-encoder connection according to EN 61800-5-2 requires that the encoder is seated properly. Wobbling must be measured each time an ES7S, AS7W, or AS7Y encoder is installed to ensure it is seated properly.

Measure wobbling as described in the following chapter.

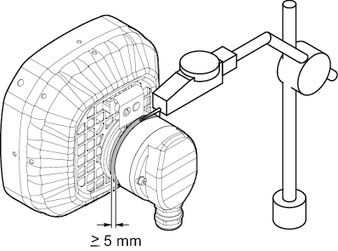

- Place the sensor on the upper edge of the encoder as shown in the figure below:

- The measurement must be made within the indicated zone (maximum width = 5 mm).

- Turn the motor shaft. If required, start up the motor at low speed (< 60 min-1).

- Check the wobble on the sensor.

- The maximum permitted wobble on the encoder must be ≤ 0.07 mm when turning the motor shaft.

Additional information