Example

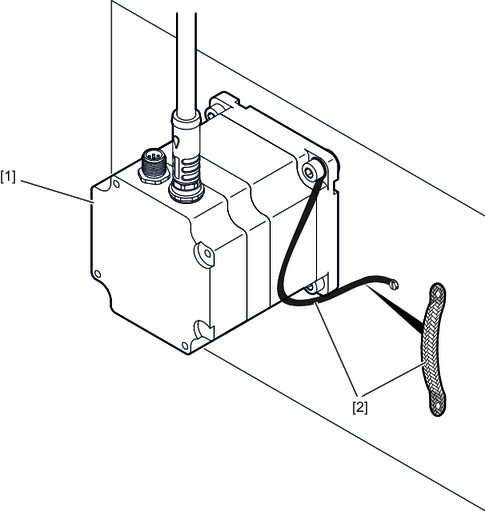

The following figure shows the connection options for the equipotential bonding via HF litz wire and FE conductor in the voltage supply:

[1] | If you install a drive unit without a hollow shaft, this results in a large, conductive connection between the drive unit and the mounting plate. In this case, the entire contact surface must be electrically conductive (e.g. unpainted). |

[2] | FE ground connection on the housing, e.g. via ground strap (HF litz wire, no. 2) The contact surfaces must be electrically conductive (e.g. unpainted). For improved low-impedance grounding at high frequencies, SEW‑EURODRIVE recommends using corrosion-resistant connecting elements. Tighten the M5 screw with a tightening torque of 2.0 Nm – 2.5 Nm. |

- Do not use data cable shields for the equipotential bonding.