Overload guard

By using the "overload guard" function, the axis group members remain synchronous even in the event of overload. For this purpose, the overload guard analyzes the current acceleration capability of each individual axis group member based on its actual torque, the current integral part of the speed controller and other parameters, and in this way determines whether the axis group member can still follow the setpoint profile.

The following examples illustrate the operating principle of the overload guard by mapping the characteristic curves during a positioning process with 2 axis group members:

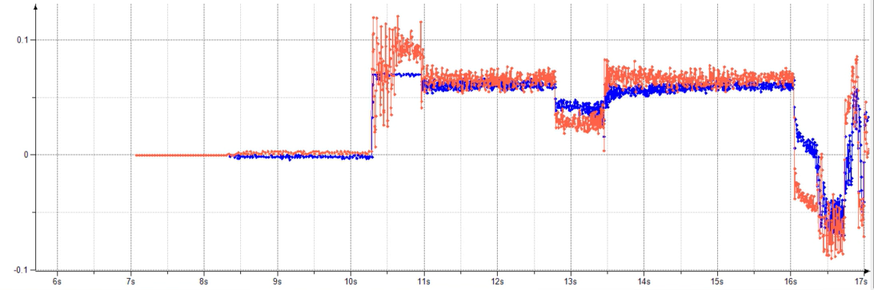

Overload guard activated

The following diagram shows the torque curve of axis group member 1 (blue) and axis group member 2 (orange). To overload axis group member 1, its torque has been limited to 7% so that the desired acceleration is no longer achieved. This torque limitation can be seen in the following figure in the form of the plateau of the blue characteristic curve between seconds 10 and 11.

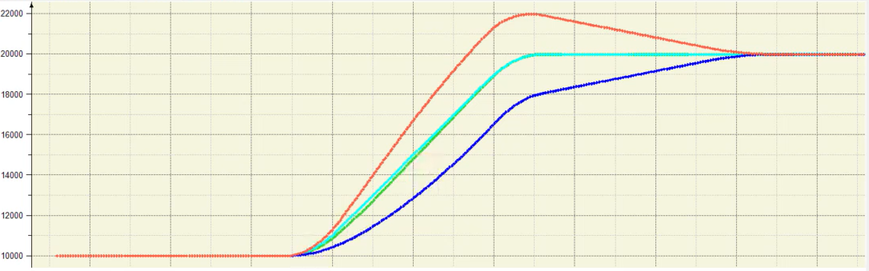

The following diagram shows the position profile of the application (orange) and the setpoint profile (turquoise). Due to the overload, the application can no longer follow the setpoint profile.

If this lag error becomes too high, a switch-off can occur, but not a position offset between the two axis group members because axis group member 2 adapts to the restricted dynamics of axis group member 1 and therefore remains position-synchronous. The overload guard in this way prevents a skew between the axis group members, for example in the event of an overload.

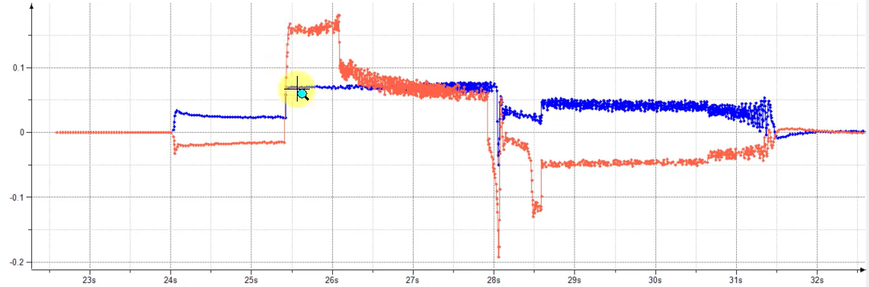

Overload guard deactivated

The following diagram shows the torque curve of axis group member 1 (blue) and axis group member 2 (orange). To overload axis group member 1, its torque has been limited to 7% so that the desired acceleration is no longer achieved. This torque limitation can be seen in the following figure in the form of the plateau of the blue characteristic curve between seconds 26 and 27.

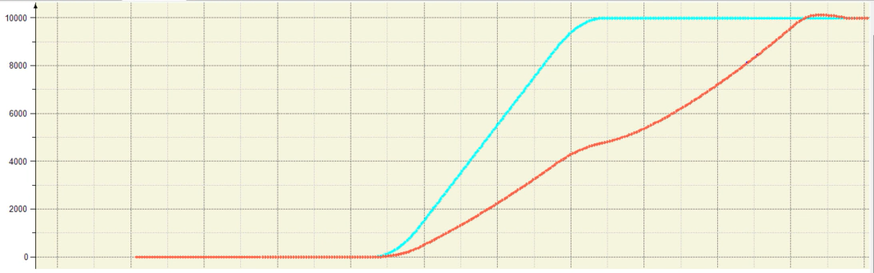

The following diagram shows the position profile of axis group member 1 (blue), axis group member 2 (orange), the mean value of the actual position of both axis group members (green), and the setpoint profile (turquoise). Due to the overload, axis group member 1 can no longer follow the setpoint profile. However, to ensure that the mean value of the actual position of both axis group members follows the setpoint profile, axis group member 2 must compensate for the missing dynamics. This results in a significant skew between the axis group members (offset from blue to orange).