Selecting the MOVIGEAR® classic drive unit

Observe the following points when selecting the drive unit MOVIGEAR® classic:

- Which torque class (size) is required?

- Requirement: The maximum possible startup torque of the drive unit MOVIGEAR® classic must be higher than the maximum application torque:

- Based on the application calculations, the maximum application torque for startup is Mmax = 145 Nm

- MGF..2-DSM-C drive units with i > 10.37 meet this requirement.

- Result: A MOVIGEAR® classic of torque class MGF..2 is selected.

- Selecting the gear ratio with output speed:

- Requirement: The application calculations result in an output speed of na = 50 min-1. To achieve a high setting range and optimum efficiency, the required output speed should be achieved as precisely as possible at an input speed of ne = 2000 min-1.

- Result: The drive with a gear ratio of itot = 37.24 and an output speed of na = 53.71 at ne= 2000 min-1 is selected from the table in the product manual in chapter "Technical data" > Permitted currents, speeds and torques:

MGF..2-DSM-C | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

na | Ma | Icont. | Mapk | Imax | Ma_eso | itot | Weight | |||

at ne= 2000 min-1 | ||||||||||

min-1 | Nm | A | Nm | A | Nm | kg

| ||||

2- | 593.47 | 15 | 2.08 | 46 | 5.73 | 145 | 3.37 | 15.7 | ||

... | ... | ... | ... | ... | ... | ... | ||||

... | ... | ... | ... | ... | ... | ... | ||||

... | ... | ... | ... | ... | ... | ... | ||||

3-stage |

| 71.25 | 126 | 2.08 | 220 | 3.30 | 330 | 28.07 |

| 16 |

| 60.57 | 149 | 2.08 | 220 | 2.80 | 330 | 33.02 |

| ||

53.71 | 168 | 2.08 | 220 | 2.50 | 330 | 37.24 | ||||

| 47.40 | 190 | 2.08 | 220 | 2.20 | 330 | 42.19 |

| ||

| 44.41 | 200 | 2.08 | 220 | 2.10 | 330 | 45.03 |

| ||

| 38.83 | 200 | 1.80 | 220 | 1.80 | 330 | 51.51 |

| ||

| 36.20 | 200 | 1.70 | 220 | 1.70 | 330 | 55.25 |

| ||

- Checking the setting range and minimum speed

- Setting range 5 m/min: 22 m/min ≈ 1:4.4.

- Check the setting range and the resulting minimum speed in combination with the properties of the control mode of the connected inverter. Select an encoder option if required.

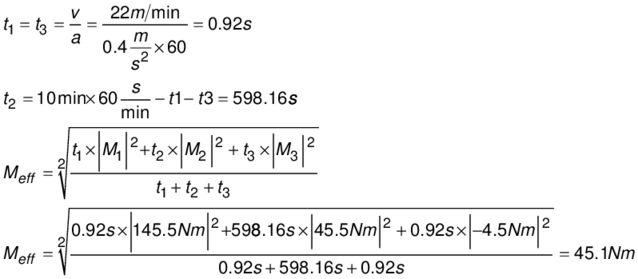

- Thermal check of MOVIGEAR® classic:

- Requirement: In order to avoid thermal problems, the effective torque of the application must be smaller than the continuous output torque of the drive unit MOVIGEAR® classic:

- Based on the application calculation, the effective torque is Meff = 45.1 Nm. The continuous output torque of the selected MOVIGEAR® drive unit is Ma at ne 2000 min-1 = 149 Nm.

- If applicable, observe derating factors (derating for installation altitude and ambient temperature).

- Result: The requirements are met.