Curve profiles

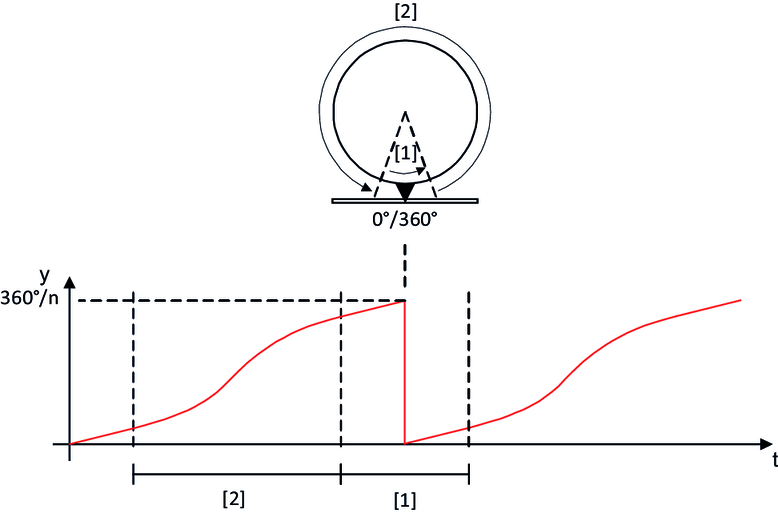

The "rotary knife" function generates the curve profiles in such a way that a product length results when the curve profile is run through. The product length is set during movement [2]. The cut is made during synchronous movement [1]. With position 0 ° of the rotary knife, the tool is perpendicular to the product.

[1] | Synchronous movement |

[2] | Movement for setting the product length |

The following basic curves of the curve profiles can result. The theoretical scenario where the knife length is exactly the same as the product length is not considered.

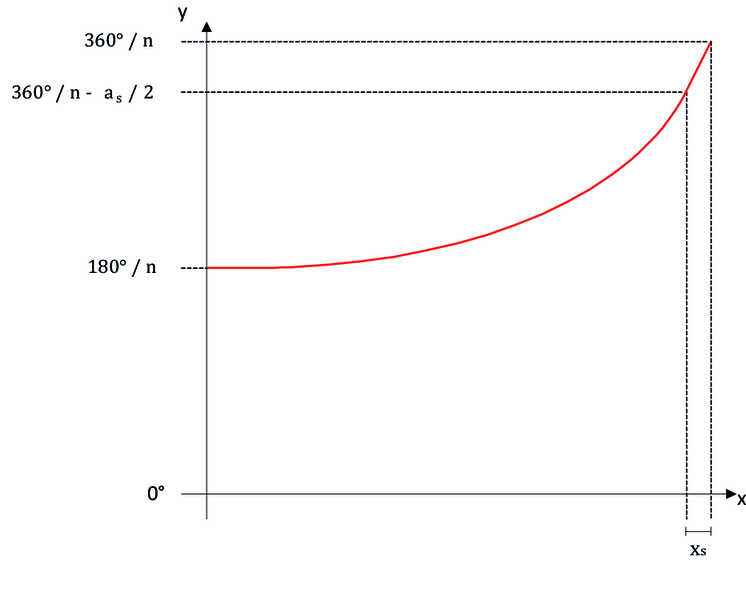

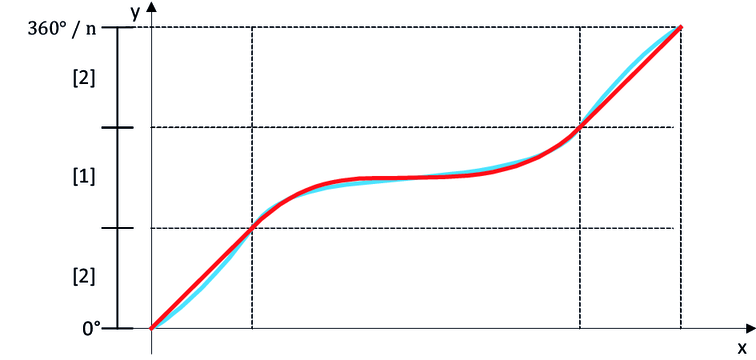

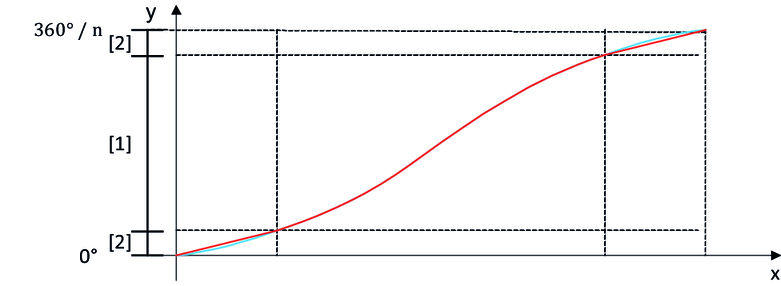

Knife length < nominal product length

If the knife length is less than the product length, the knife has to reduce its speed between the cutting areas. This results in the following profile (red – thin material; blue – thicker material and speed compensation in the cutting area):

[1] | Curve section with reduced speed (undersynchronism) |

[2] | Curve section in the cutting area |

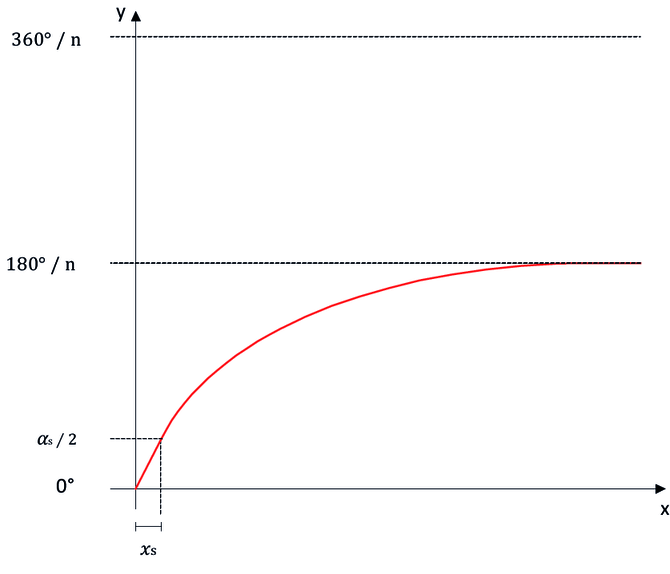

Knife length > nominal product length

If the knife length is greater than the product length, the knife has to increase its speed between the cutting areas. This results in the following profile (red – thin material; blue – thicker material and speed compensation in the cutting area):

[1] | Curve section with reduced speed (oversynchronism) |

[2] | Curve section in the cutting area |