Removing/installing conical encoders and encoder mounting adapters for conical encoders

INFORMATION

For EK8Z, EK9Z, AK8Z encoders, work on the MOVILINK® DDI communication unit is not permitted. Place an order with SEW-EURODRIVE Service to have any necessary work on the encoder performed.

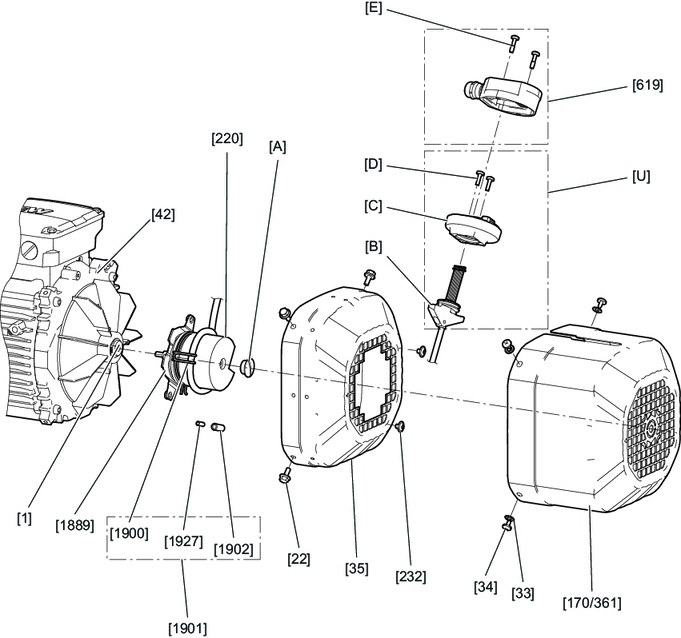

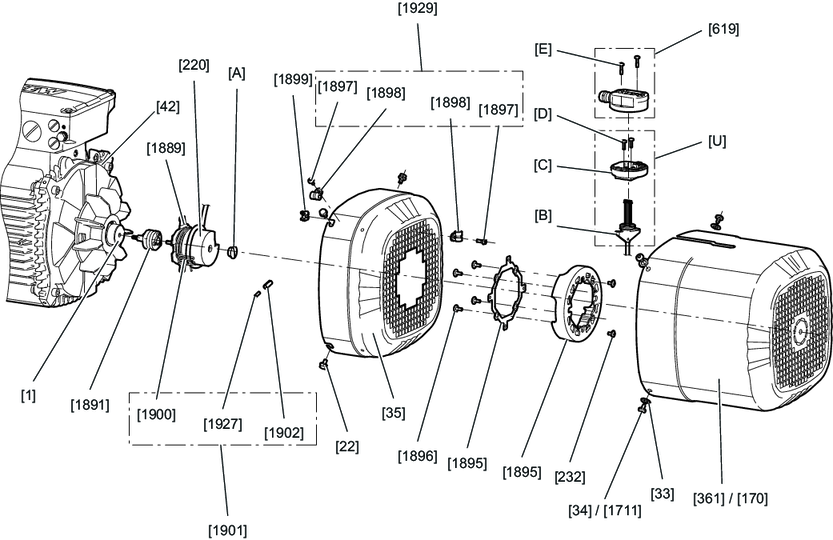

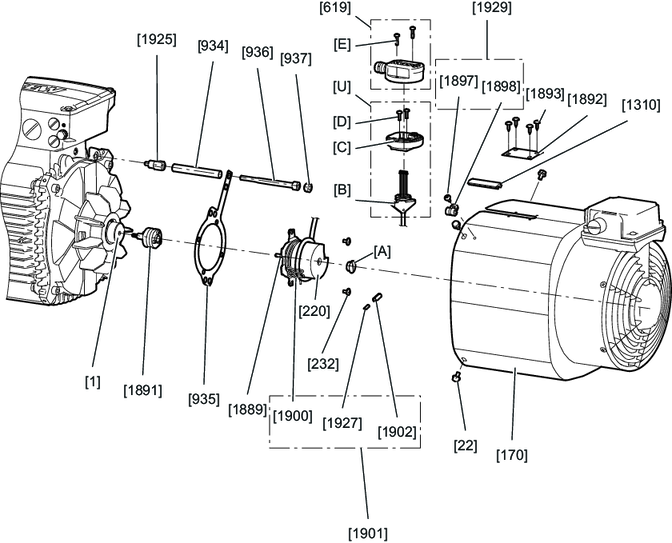

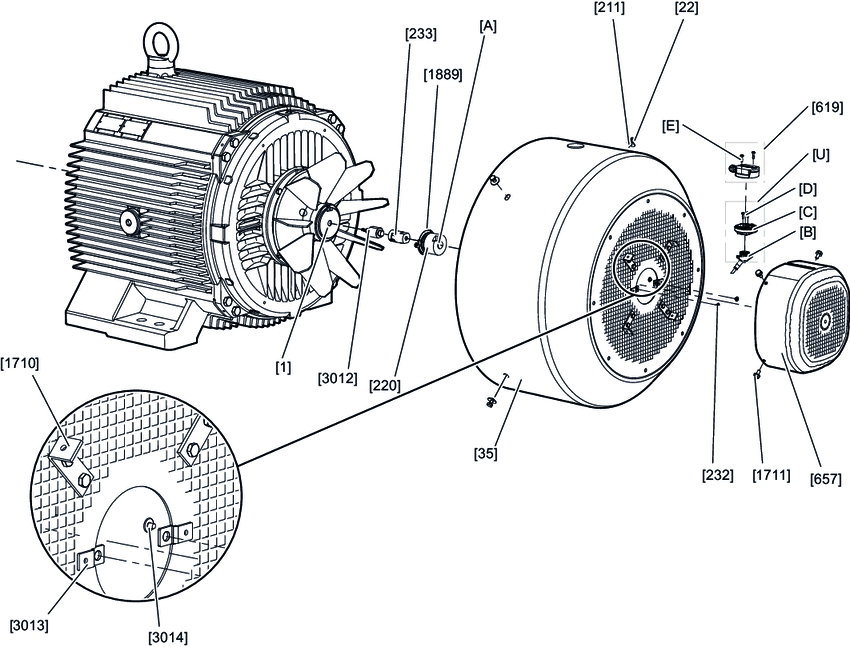

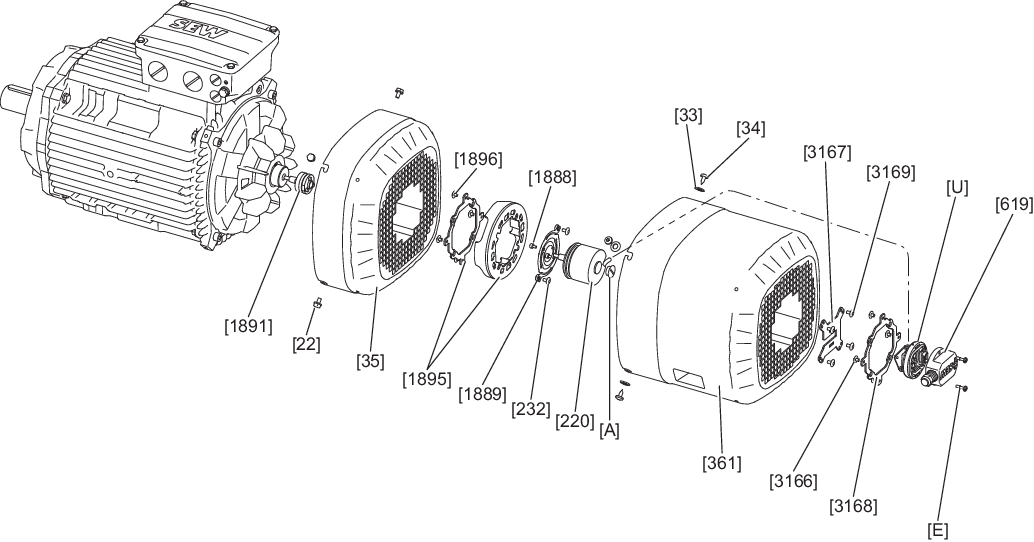

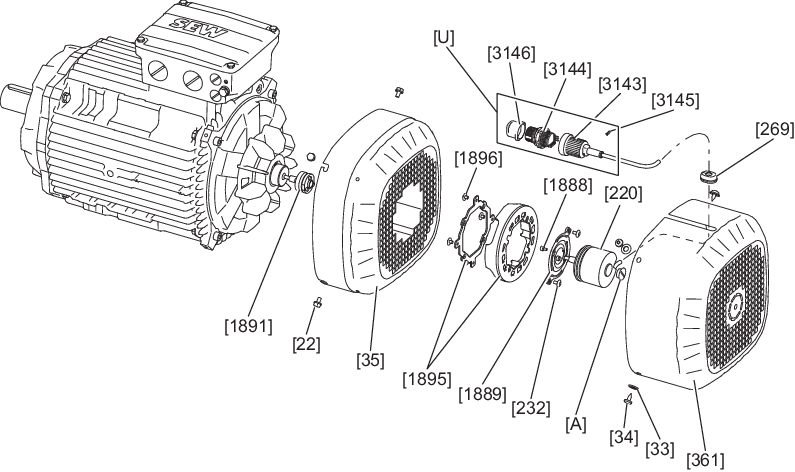

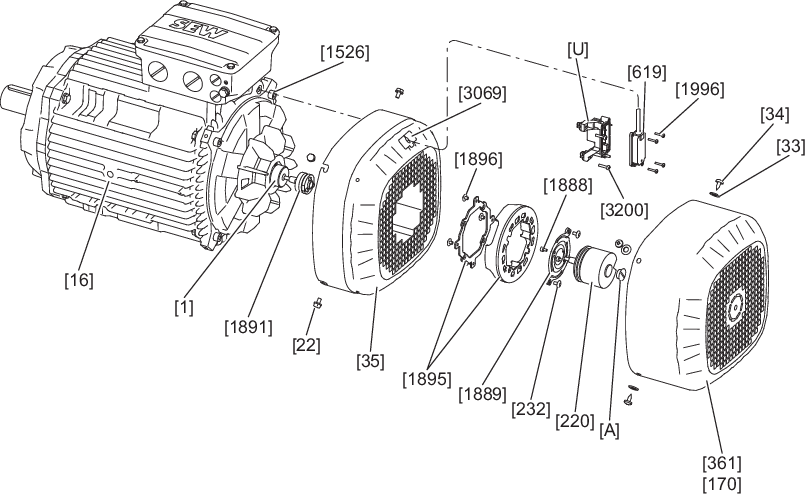

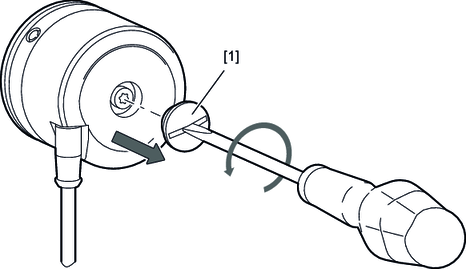

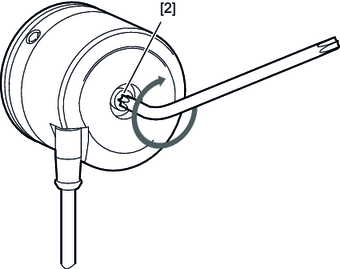

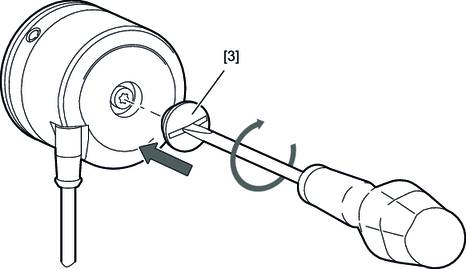

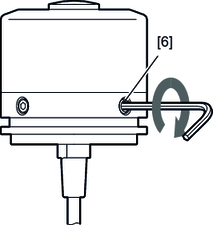

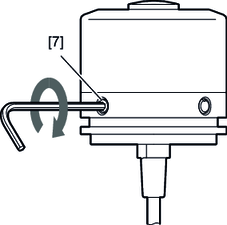

The integrated encoder plug connector (parts [U] and [619]) can be turned ± 180 degrees in steps of 90° to allow for a variable cable outlet of the connection cover [619]. To align, loosen the screws D in the lower part C.

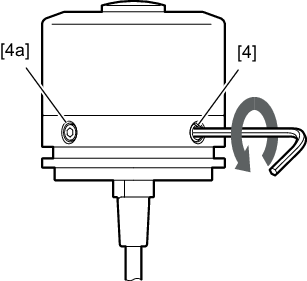

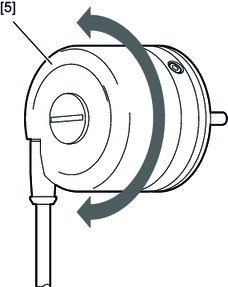

In addition, the encoder cover [361] can be turned 360 degrees in steps of 90° for many motor configurations to allow for a variable connection side of the integrated encoder plug connector (parts [U] and [619]). Loosen the screws [34] and the washers [33]. The ability to turn parts can be restricted by the following design features of the motor:

- Size

- Position of the manual brake release

- Certain gear unit combinations

- Dimensions of the feet of the motor

- Connection technology of the motor (e.g. plug connectors)

- Combination with a forced cooling fan

- Applicative limits of the system

Additional information

- EK8./EK9./AK8./AK9./RK8M conical encoders and EK8A encoder mounting adapters – (E)DRN../DRU../DR2..63 – 355 motors

- Information on configuring the zero-angle position for EK8W/AK8H/AK8W/EK9Z/AK8Z/RK8M encoders on the DR2C.. motor

- Additional work for the RK8M encoder on the DR2C.. motor

- Additional work for EK8W, AK8H, AK8W, EK9Z, and AK8Z encoders on the DR2C.. motor