Additional work for the RK8M encoder on the DR2C.. motor

Required tools:

- Slotted screwdriver 1.6 × 8.0 mm

- Torx screwdriver TX20

- Allen wrench 2.5 mm

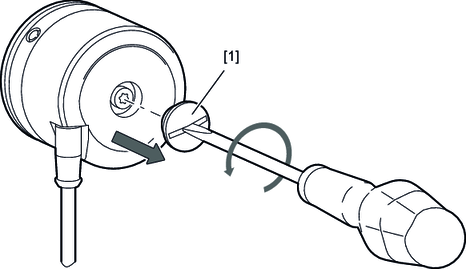

- Remove the screw plug [1] from the resolver.

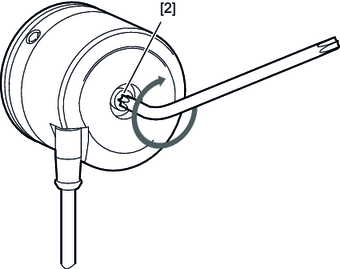

- Install the resolver by tightening the M5 central screw [2] with 3.3 Nm on the customer shaft.

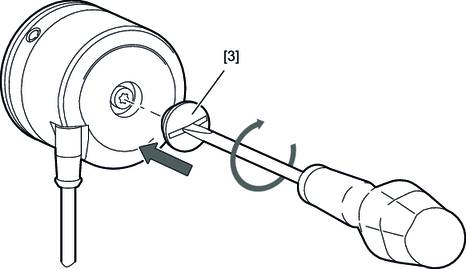

- Reinstall the screw plug [3] on the resolver with 1.8 Nm.

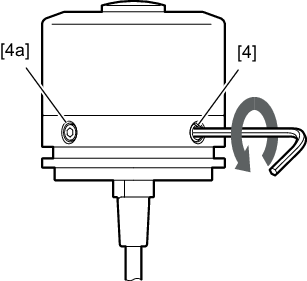

- When installing for the first time, loosen the set screw [4] slightly. When reinstalling, the set screw [4a] must also be loosened slightly.

- The rear part of the resolver can now be moved.

Resolver setting specifications for synchronous motors from SEW-EURODRIVE

Number of pole pairs for motor: pM = 3, number of pole pairs for resolver: pR = 1

Setting specification:

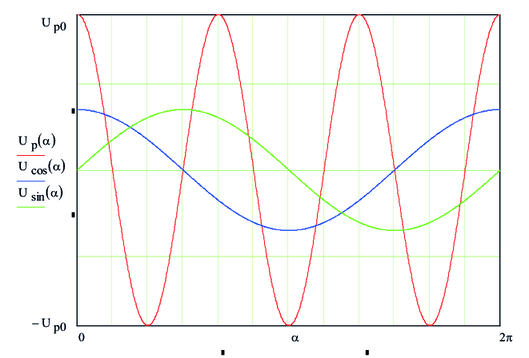

Resolver zero position (Ucos (S1 – S3) positive maximum, Usin (S2 – S4) positive zero crossing) coincides with positive maximum of excitation in magnetic circuit (EMF) Up in phase u (with clockwise rotor rotation as viewed on the output shaft end).

Motor terminal | U | V | W |

Supply | open | minus | plus |

a) Adjustment check

- The motor is unloaded and the brake released. The rotor can freely align itself in the stator field. Supply the motor with direct current 60 – 80% I0 (for a maximum of 10 minutes).

- The rotor aligns in the field.

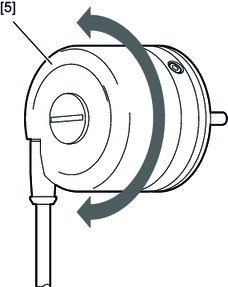

- Turn the movable part [5] of the resolver until:

- S2 – S4 (Usin) positive zero crossing

- S1 – S3 (Ucos) positive maximum

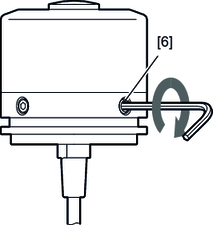

- Tighten the set screw [6] that was loosened at point (4) again with 1.2 Nm.

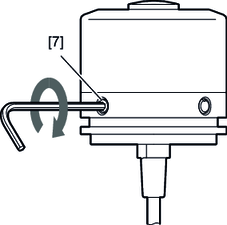

- Tighten the set screw [7] with 1.2 Nm.

- Perform a direction of rotation check. To do so, change the supply on the motor terminals (see the following table).

- The amplitude Ucos(S1 – S3) becomes smaller and the amplitude Usin (S2 - S4) becomes larger.

- End the encoder installation.

Motor terminal | U | V | W |

Supply | plus | minus | plus |

b) Adjustment check with frequency inverters from SEW-EURODRIVE

Resolver adjustment is typically performed using SEW-EURODRIVE inverter functions:

- Rotor position identification FCB18 in the "With rotating motor" procedure using the MOVISUITE® engineering software

- Encoder adjustment with MTEAdjust using the MOVITOOLS® MotionStudio engineering software

After the SEW-EURODRIVE inverter has performed the calibration process, the resolver stator will be set to the resolver rotor so that the display shows a resolver offset angle of 0.0°.