Shaft-mounted gear unit with TorqLOC® (customer shaft without contact shoulder)

Mount the drive unit on the shaft as follows:

- Perform the steps according to chapter Installation notes.

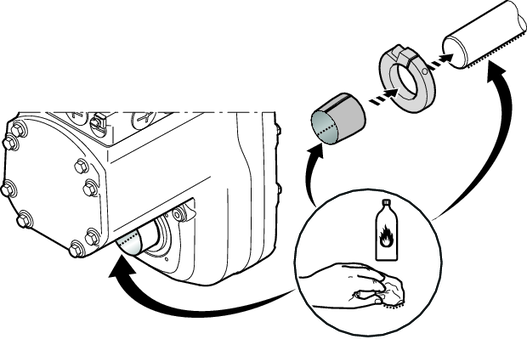

- Clean the customer shaft and the inside of the hollow shaft. Ensure that all traces of grease or oil are removed.

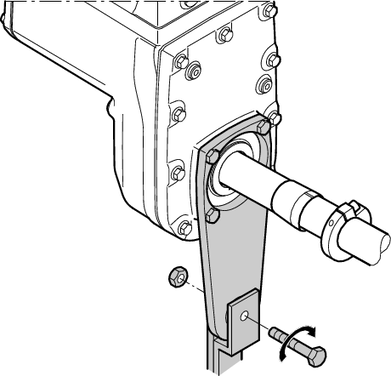

- Install the stop ring and the bushing on the customer shaft.

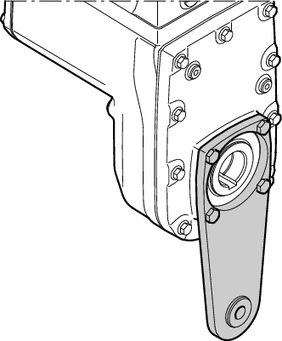

- Fasten the torque arm to the drive unit. Observe chapter Torque arm. Installation of the drive unit without a torque arm is not permitted.

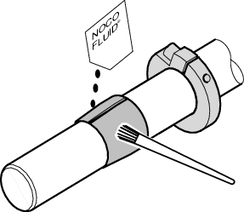

- Apply NOCO® fluid on the bushing and spread thoroughly.

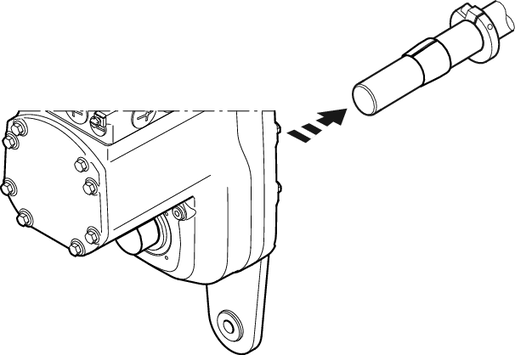

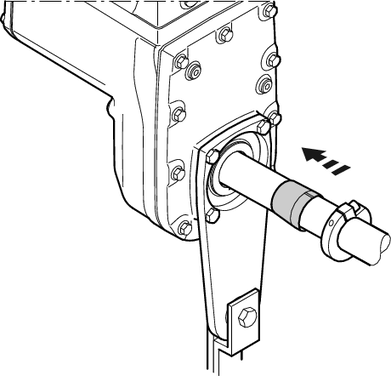

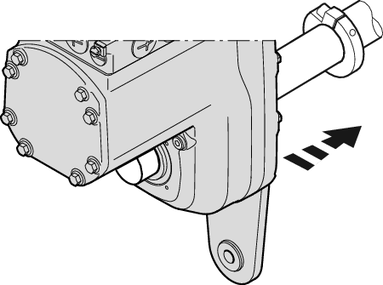

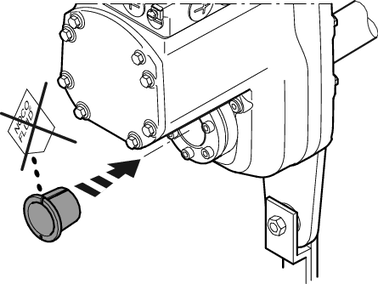

- Push the gear unit onto the customer shaft.

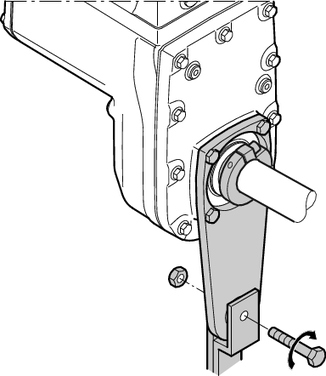

- Mount the torque arm onto the system structure/holding fixture (do not tighten the screws).

- Push the bushing into the gear unit up to the stop.

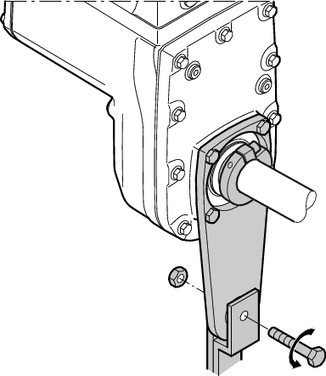

- Push the stop ring to the bushing. Mark the position of the stop ring.

- Remove the torque arm from the holding fixture/system structure.

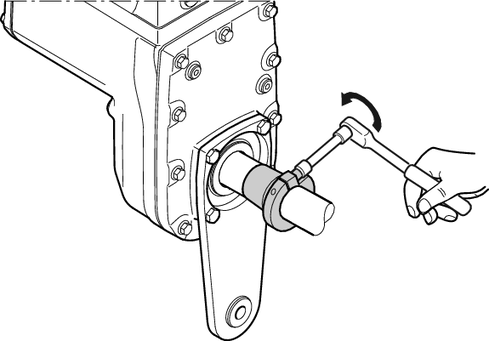

- Pull the gear unit off the customer shaft until the stop ring is accessible for fastening.

- Make sure that the position of the stop ring has not changed (see marking).

- Tighten the stop ring to the appropriate torque.

- Standard design: 18 Nm

- Stainless steel: 7.5 Nm

- Push the bushing and the gear unit onto the customer shaft up to the fixed stop ring.

- Mount the torque arm onto the system structure/holding fixture again (do not tighten the screws).

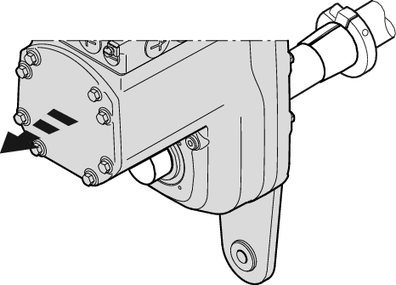

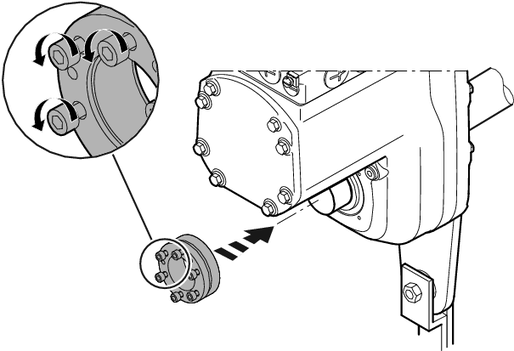

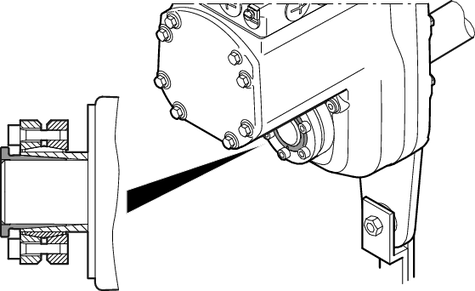

- Make sure that all screws are loosened and slide the shrink disk onto the hollow shaft.

- Slide the counter bushing onto the customer shaft and into the hollow shaft.

- In the case of a gear unit with shaft shoulder, mount the shrink disk at the shaft shoulder up to the stop. In the case of a gear unit without shaft shoulder, mount the shrink disk at a distance of 6.5 mm to 7.5 mm from the gear unit housing.

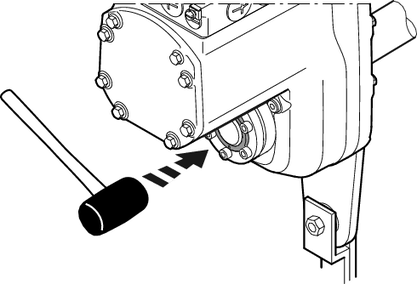

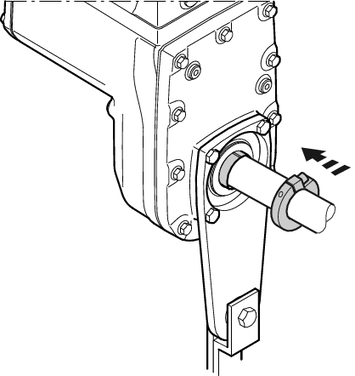

- Tap lightly on the flange of the counter bushing to ensure that the bushing is fitted securely in the hollow shaft.

- Make sure that the customer shaft is seated in the counter bushing.

- Tighten the screws of the shrink disk only hand-tight and ensure that the outer rings of the shrink disk are plane-parallel.

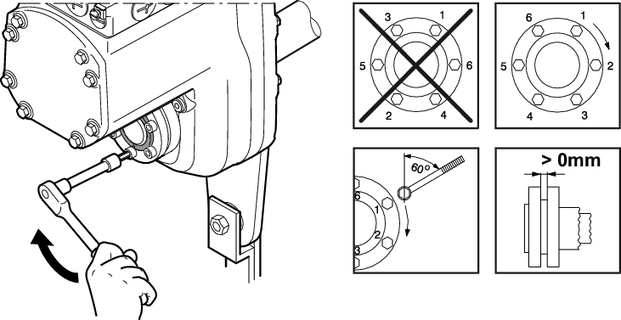

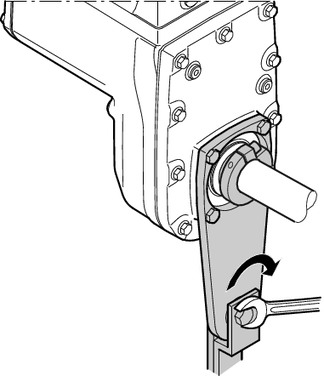

- Tighten the locking screws by working round several times from one screw to the next (not in diametrically opposite sequence):

- The exact values for the tightening torques are located on the shrink disk.

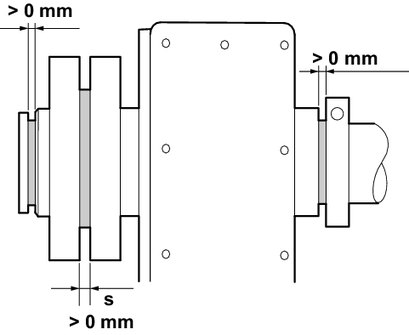

- After installation, make sure the remaining gap s between the outer rings of the shrink disks is > 0 mm.

- The remaining gap between counter bushing and hollow shaft end as well as bushing and stop ring must be > 0 mm.

- Tighten the torque arm. Observe chapter Torque arm.