Shaft-mounted gear unit with TorqLOC® (customer shaft with contact shoulder)

Mount the drive unit on the shaft as follows:

- Perform the steps according to chapter Installation notes.

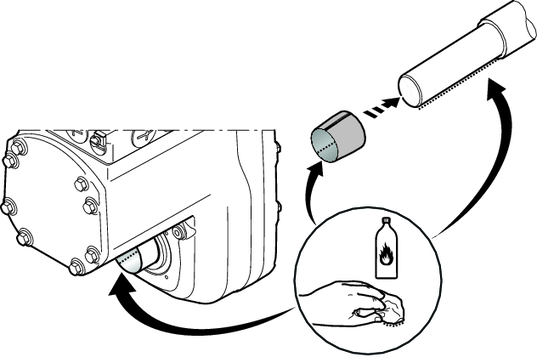

- Clean the customer shaft and the inside of the hollow shaft. Ensure that all traces of grease or oil are removed.

- Attach the torque arm to the drive unit. Observe chapter Torque arm. Installation of the drive unit without a torque arm is not permitted.

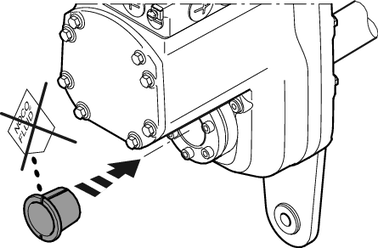

- Slide the bushing onto the customer shaft.

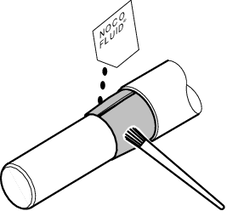

- Apply NOCO® fluid on the bushing and spread thoroughly.

- Push the gear unit onto the customer shaft.

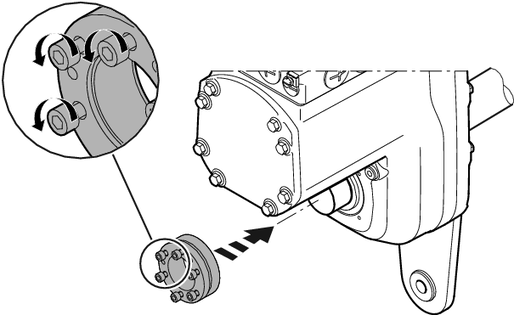

- Make sure that all screws are loosened and slide the shrink disk onto the hollow shaft.

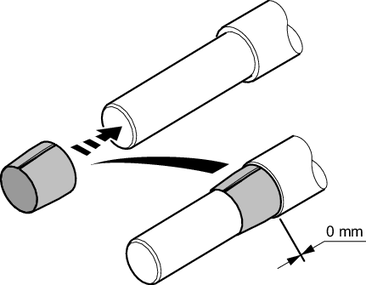

- Slide the counter bushing onto the customer shaft and into the hollow shaft.

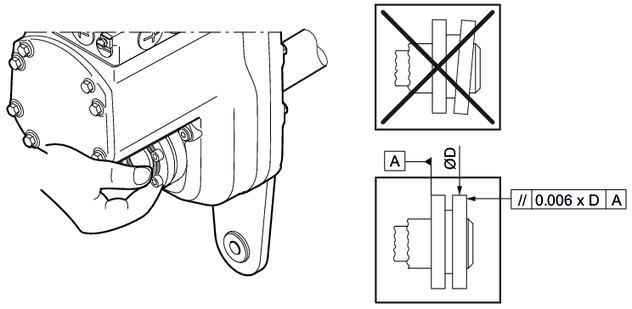

- In the case of a gear unit with shaft shoulder, mount the shrink disk at the shaft shoulder up to the stop. In the case of a gear unit without shaft shoulder, mount the shrink disk at a distance of 6.5 mm to 7.5 mm from the gear unit housing.

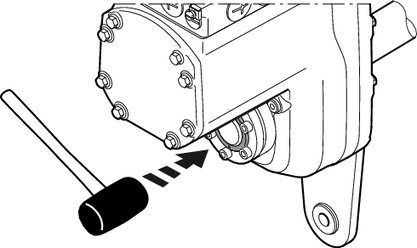

- Tap lightly on the flange of the counter bushing to ensure that the bushing is fitted securely in the hollow shaft.

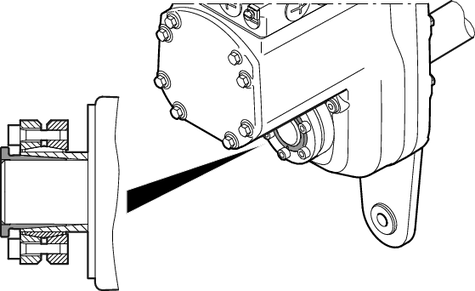

- Make sure that the customer shaft is seated in the counter bushing.

- Tighten the screws of the shrink disk only hand-tight and ensure that the outer rings of the shrink disk are plane-parallel.

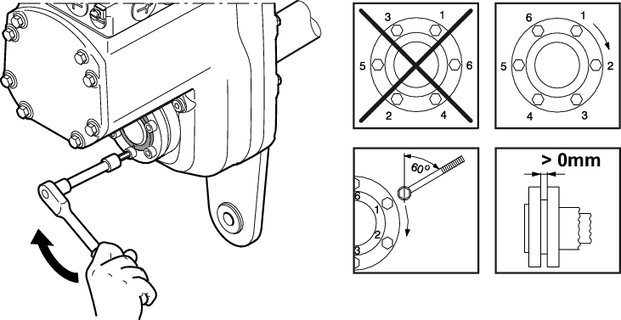

- Tighten the locking screws by working round several times from one screw to the next (not in diametrically opposite sequence).

- The exact values for the tightening torques are located on the shrink disk.

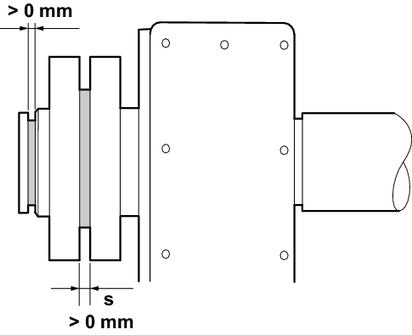

- After installation, make sure the remaining gap s between the outer rings of the shrink disks is > 0 mm.

- The remaining gap between counter bushing and hollow shaft end must be > 0 mm.

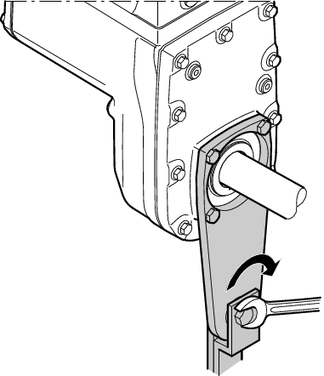

- Mount the torque arm and firmly tighten it. Observe chapter Torque arm.