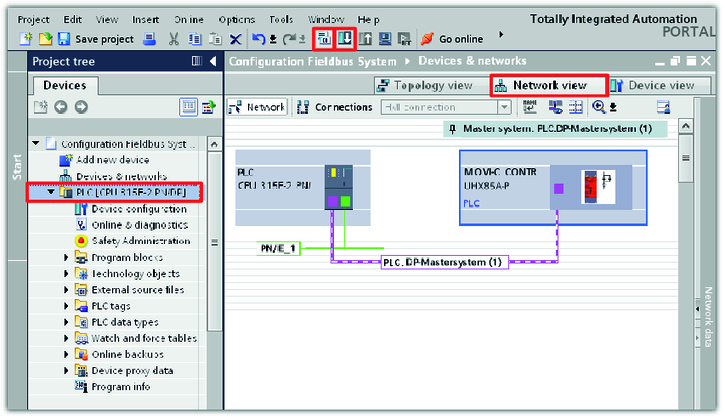

Connecting the MOVI‑C® CONTROLLER to the PROFIBUS network

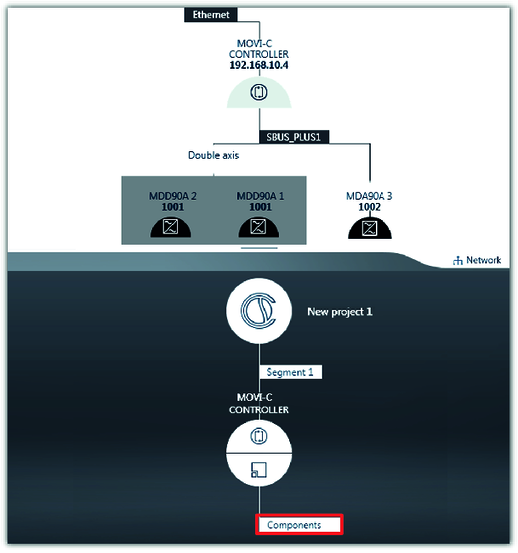

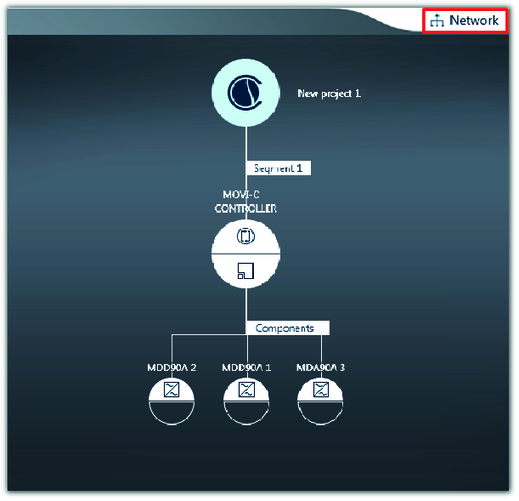

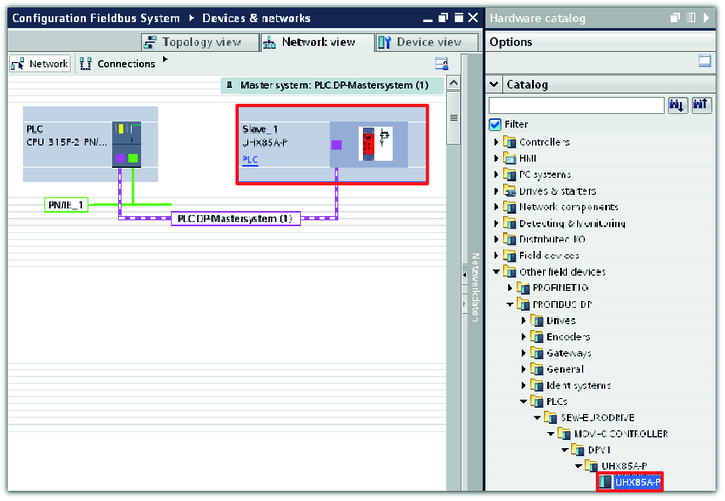

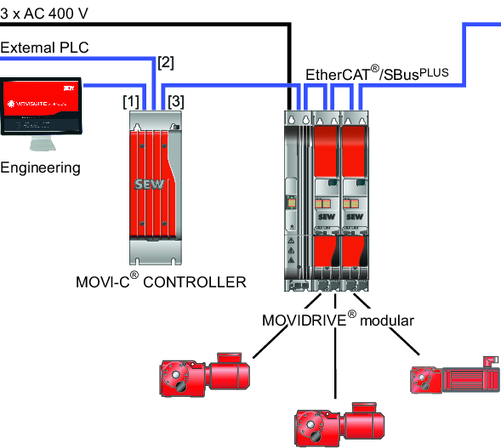

This examples explains how to connect a MOVI‑C® CONTROLLER to a PROFIBUS network. The following device topology was used in the example:

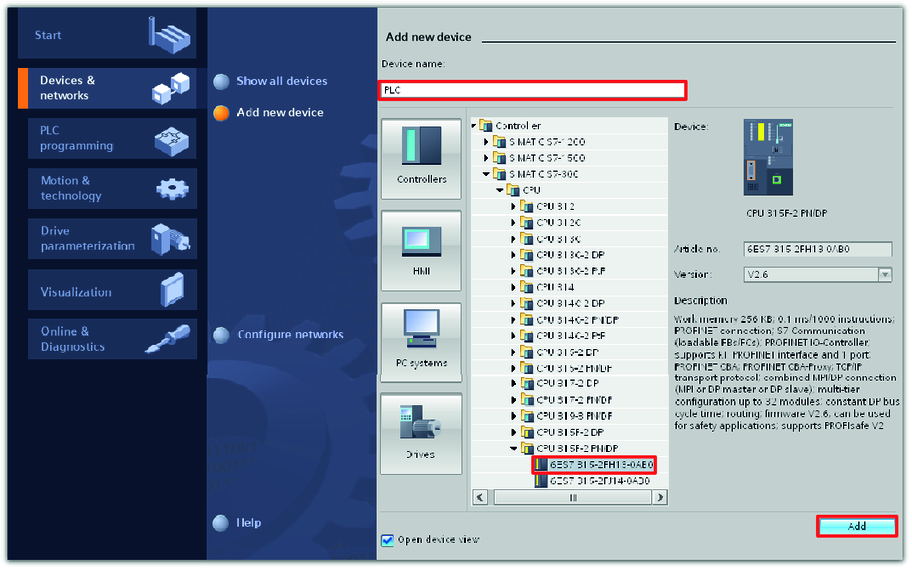

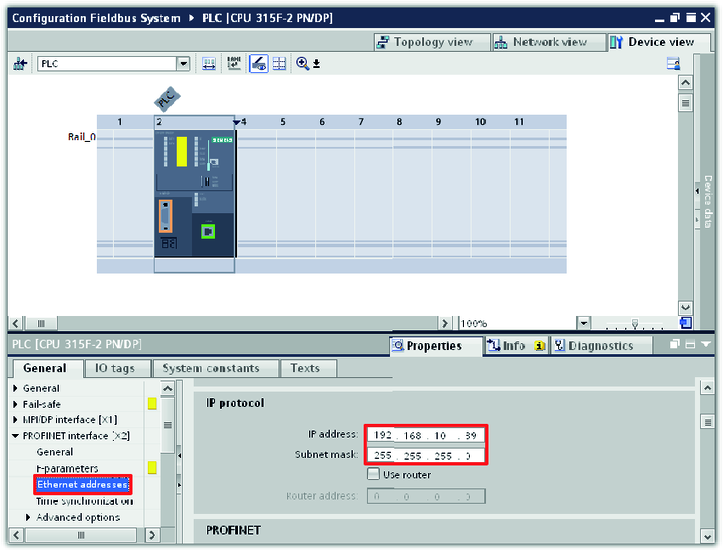

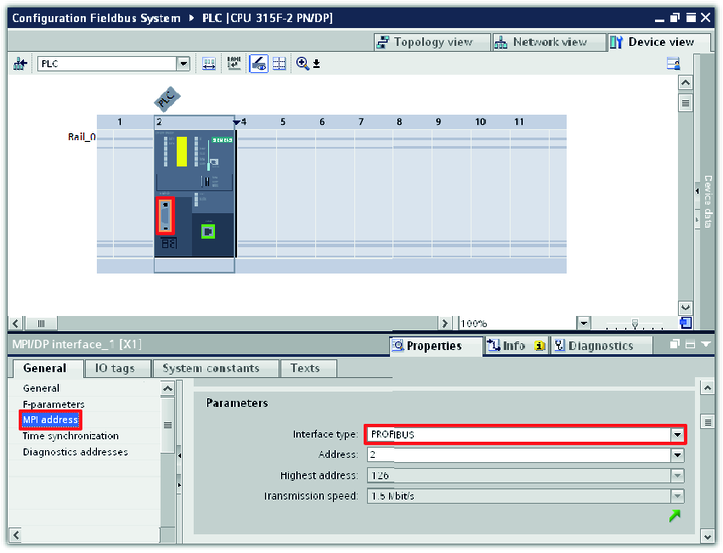

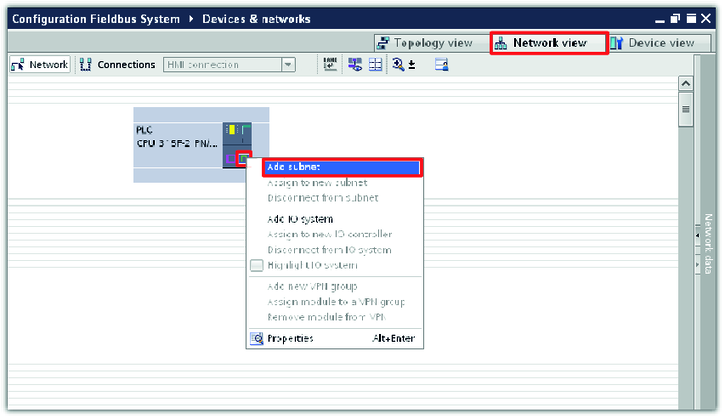

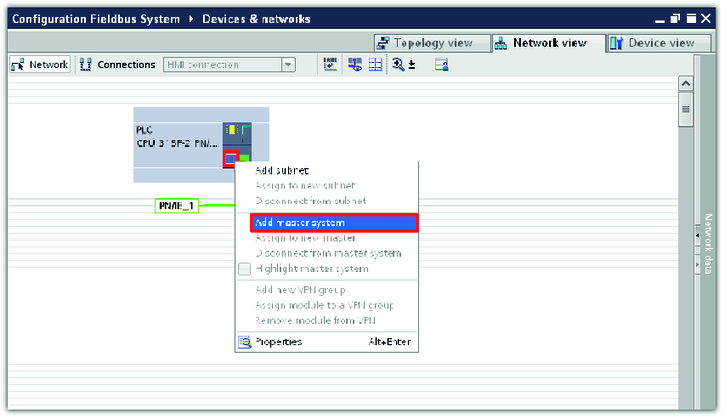

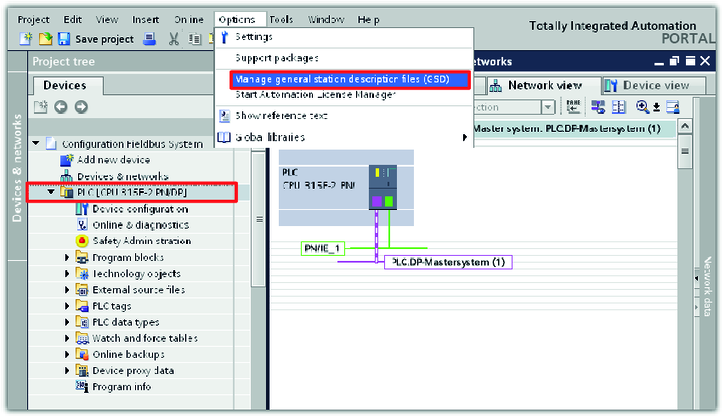

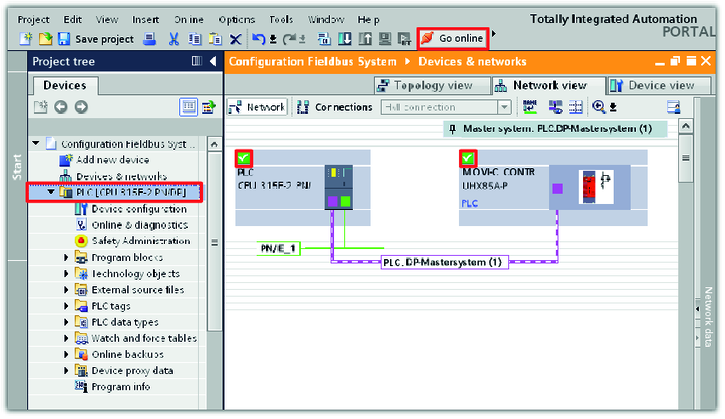

- SIMATIC S7‑300 higher-level controller with CPU 315F‑2 PN/DP

- MOVI‑C® CONTROLLER power, device design

- MOVIDRIVE® modular application inverter, MDD90A double-axis module

- MOVIDRIVE® modular application inverter, MDA90A single-axis module

[1] | Engineering interface LAN 3 |

[2] | |

[3] | EtherCAT®/SBusPLUS interface LAN 2 |

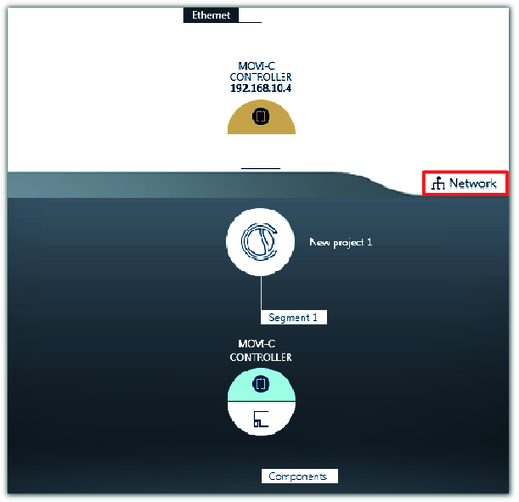

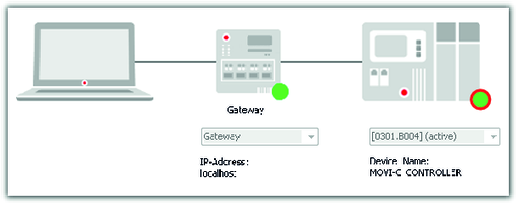

The PLC communicates with a lower-level MOVI‑C® CONTROLLER via the fieldbus interface [2]. The MOVI-C® CONTROLLER communicates with the lower-level application inverter via the EtherCAT®/SBusPLUS system bus [3]. The connection between the MOVI‑C® CONTROLLER and the engineering PC is realized via the engineering interface [1].

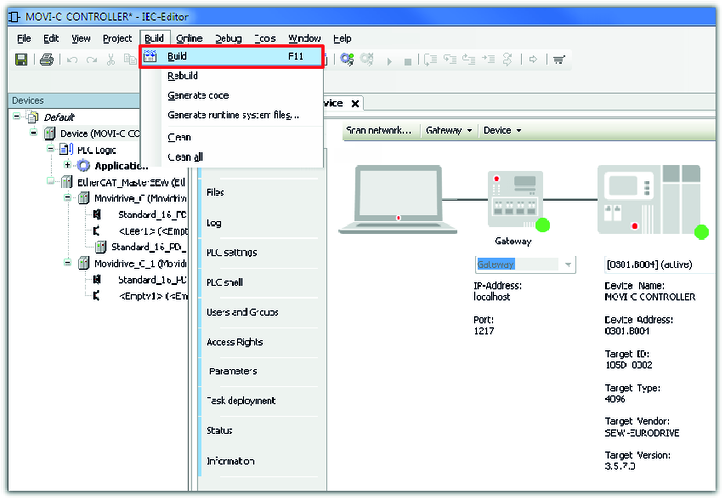

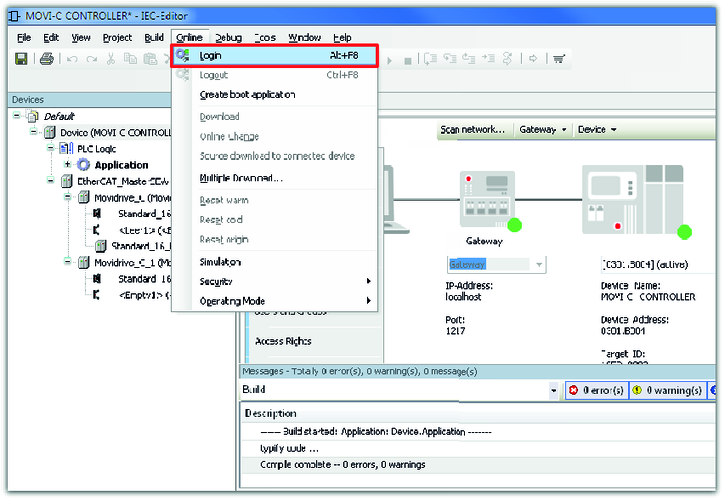

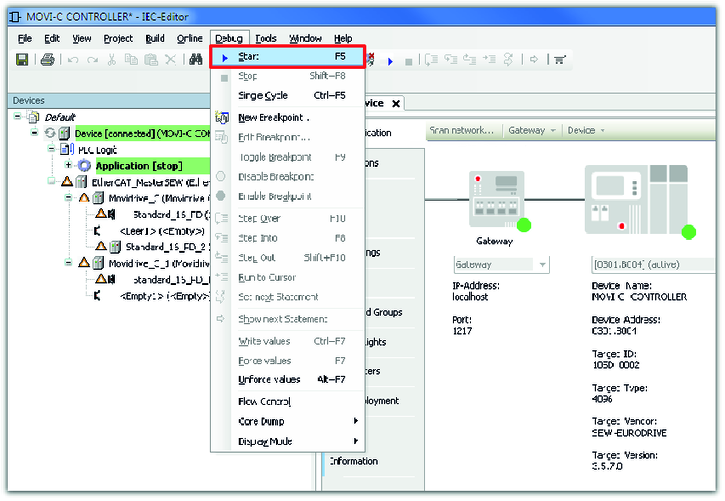

For configuration and startup of the devices, the following engineering software is used:

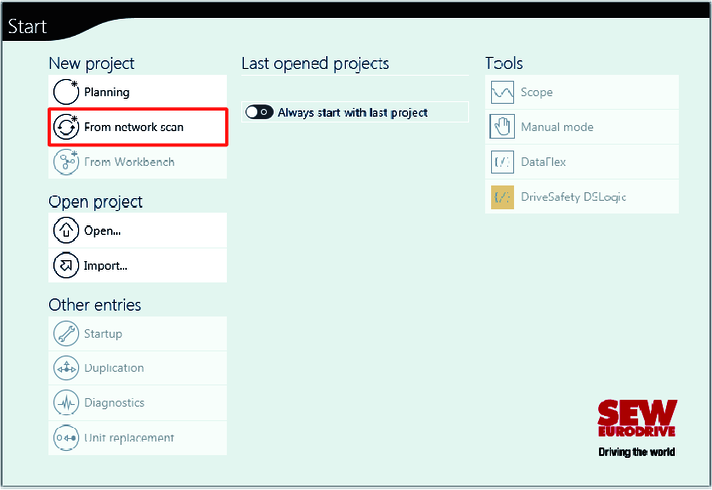

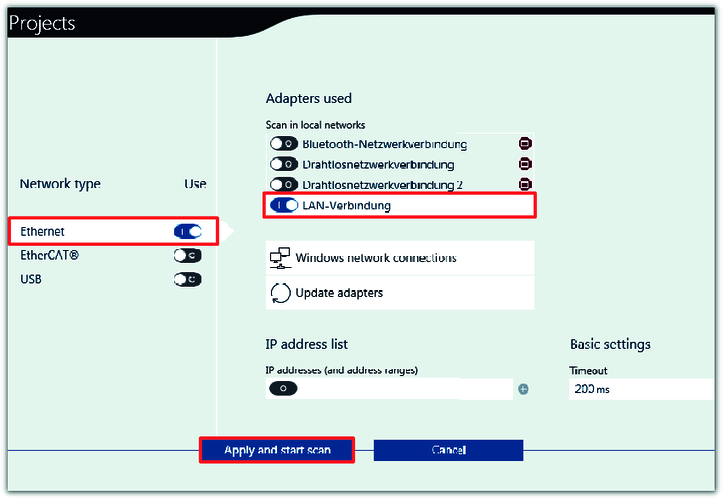

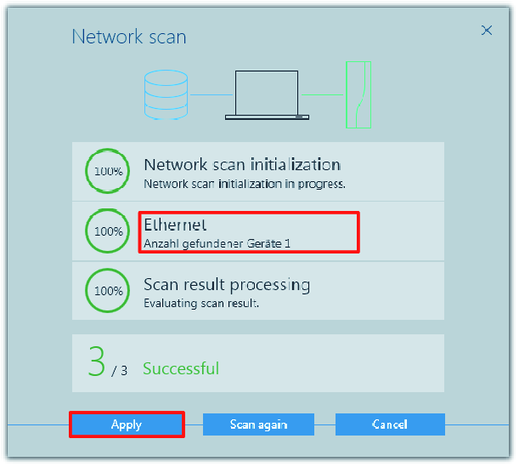

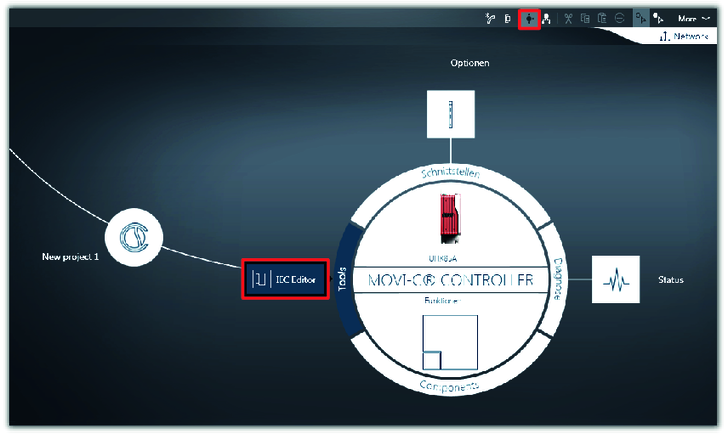

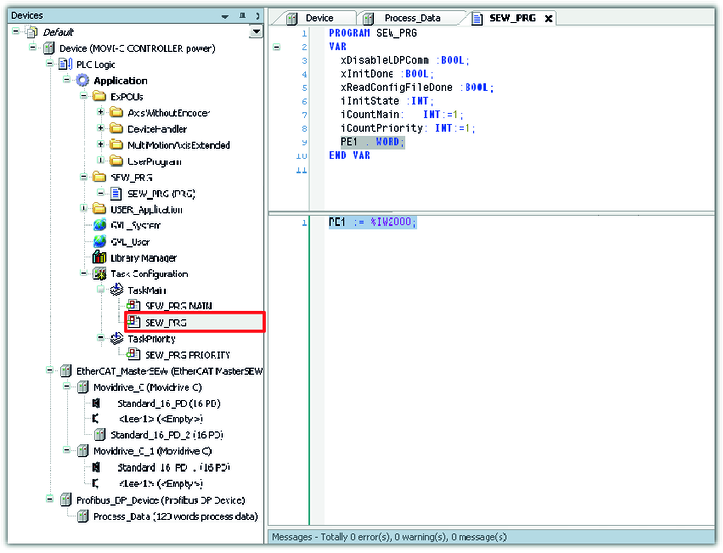

- MOVISUITE® for the MOVI‑C® devices from SEW‑EURODRIVE

- MOVISUITE® has an integrated IEC editor to configure the MOVI‑C® CONTROLLER.

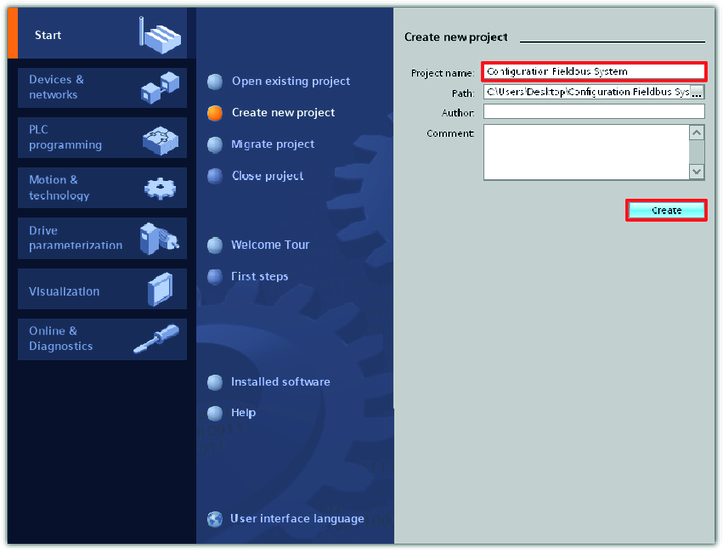

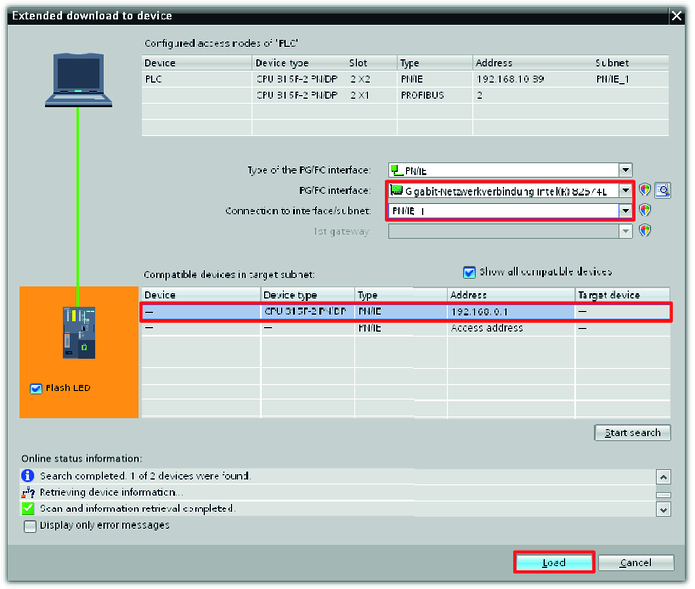

- TIA Portal (SIMATIC STEP 7) from Siemens for the PLC

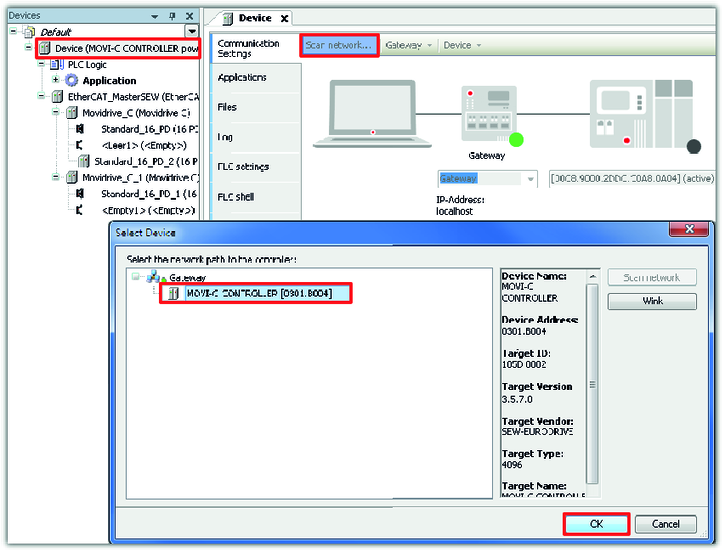

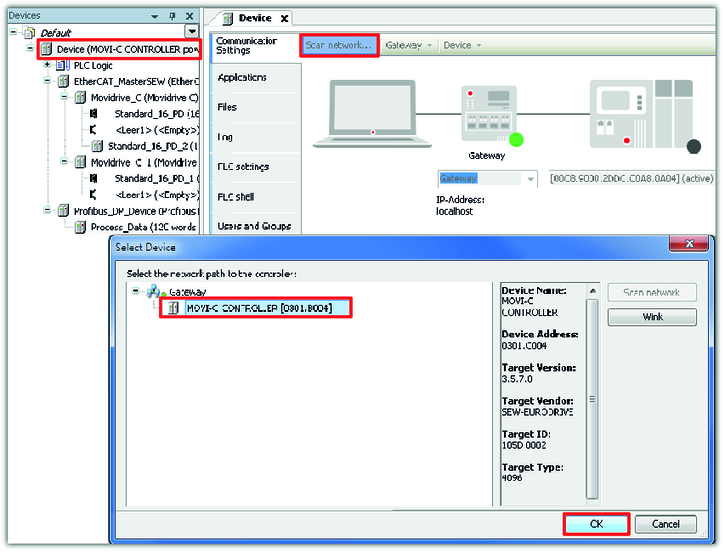

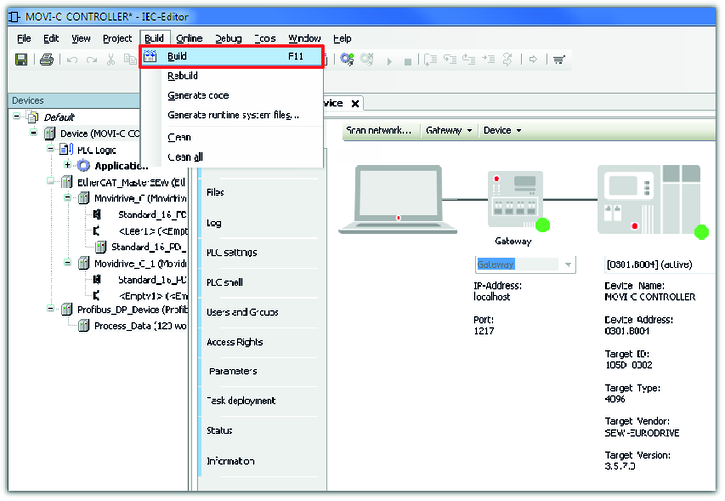

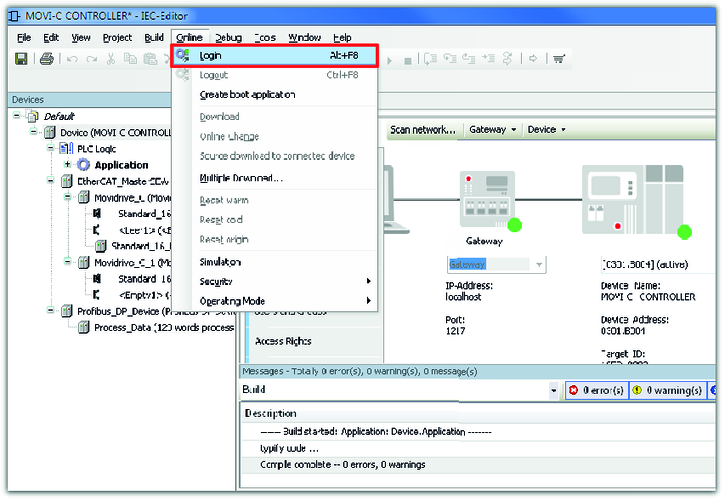

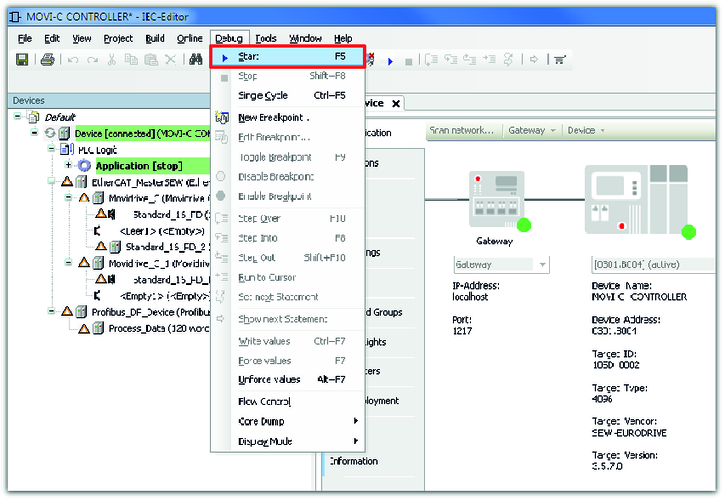

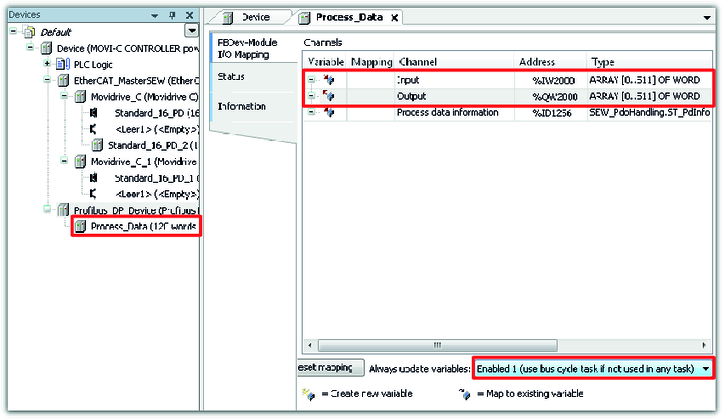

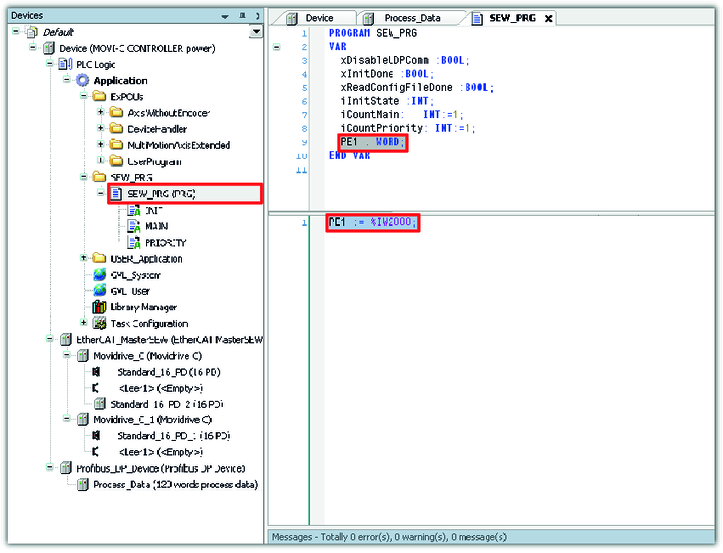

To connect the MOVI‑C® CONTROLLER to the PROFIBUS network, perform the following steps:

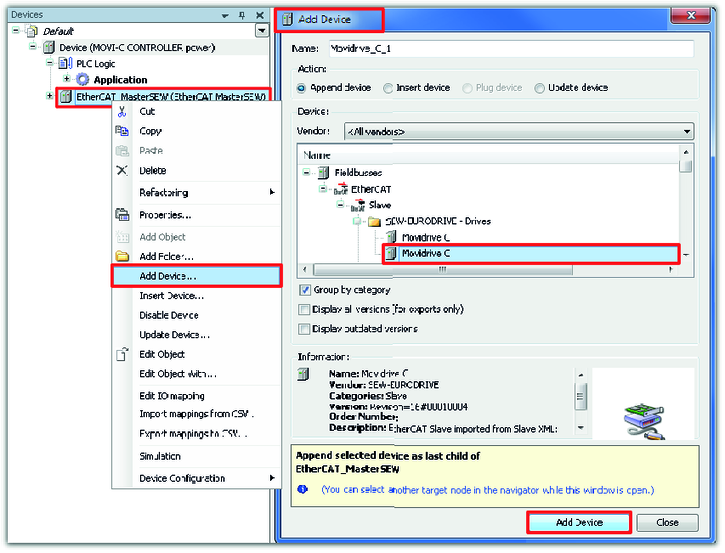

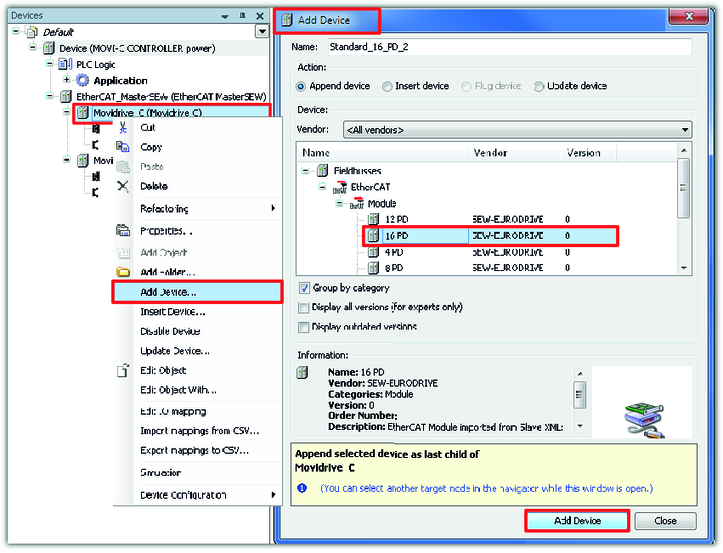

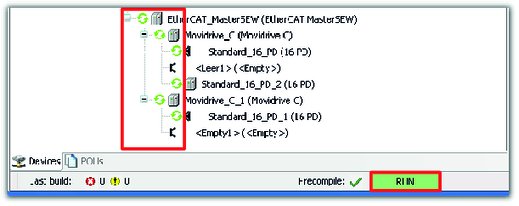

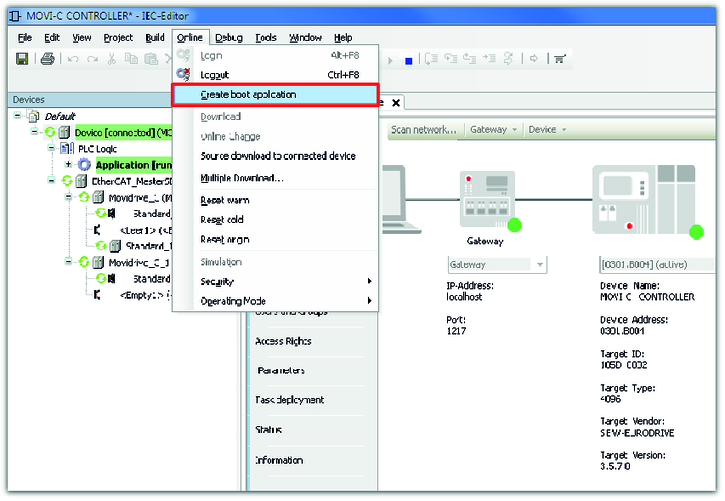

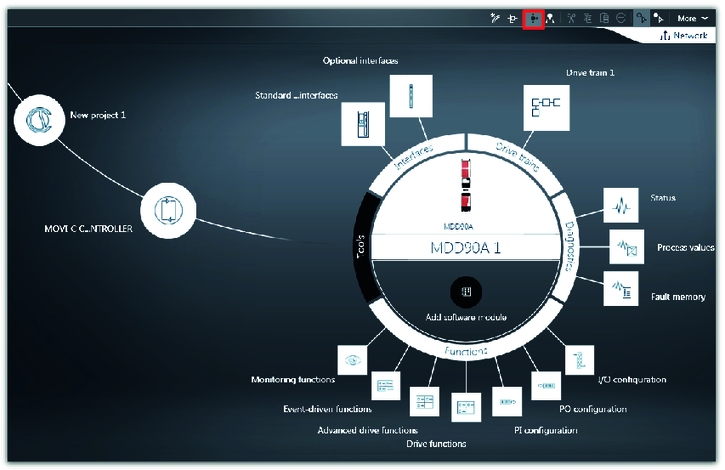

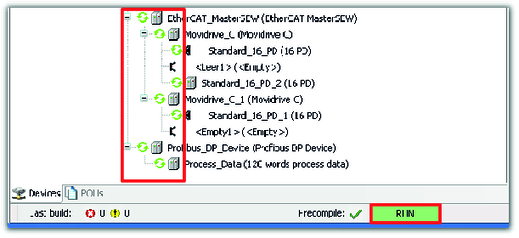

- Configuration of the EtherCAT®/SBusPLUS stations

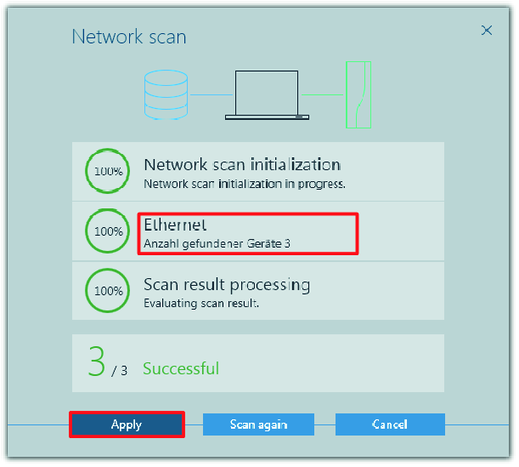

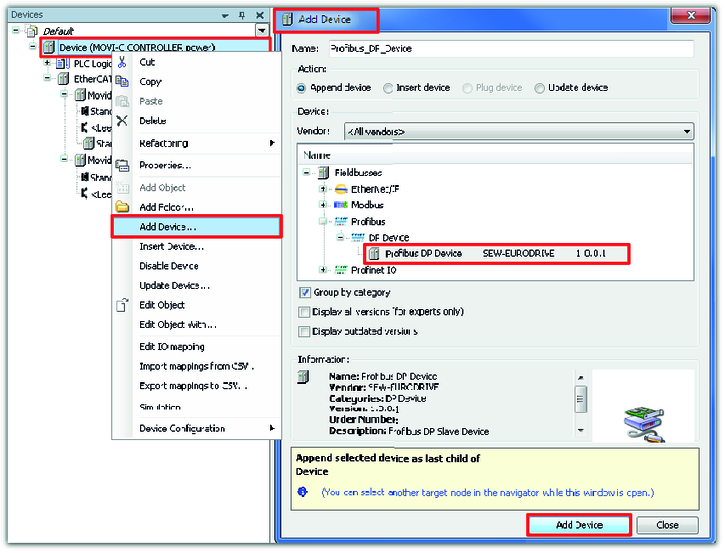

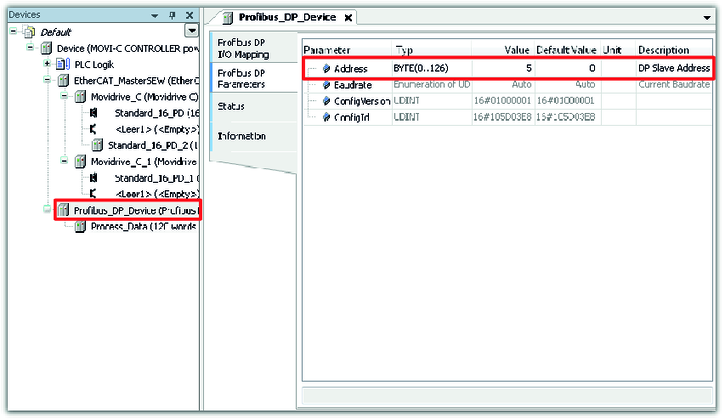

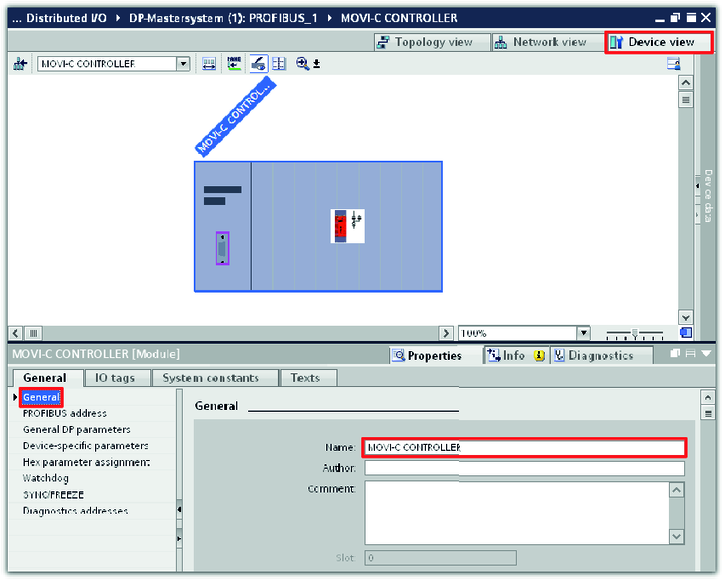

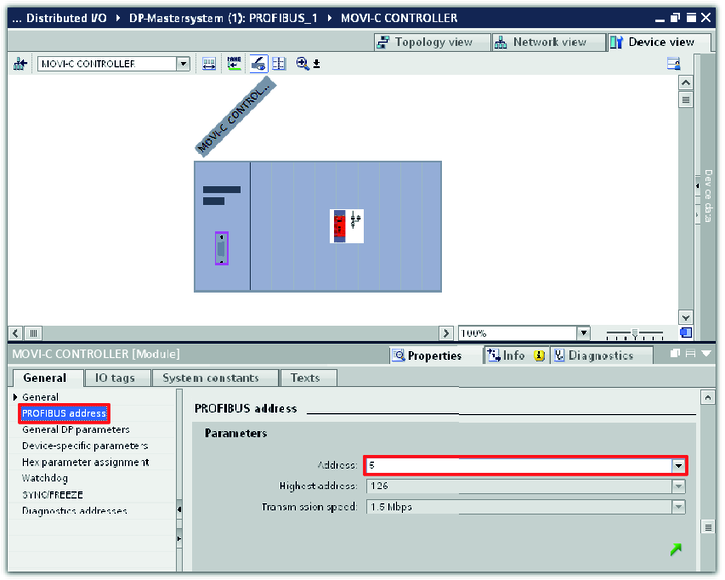

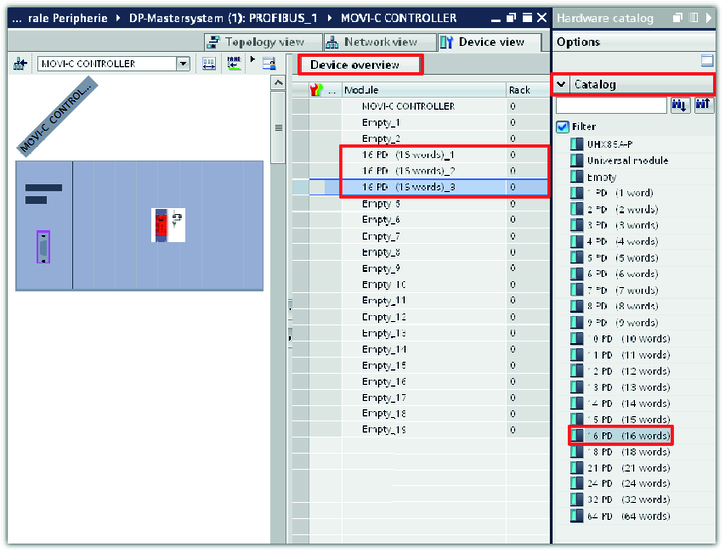

- Configuration of the fieldbus stations

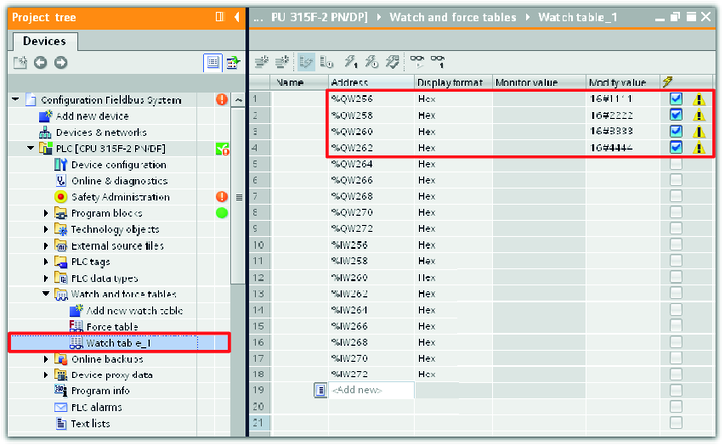

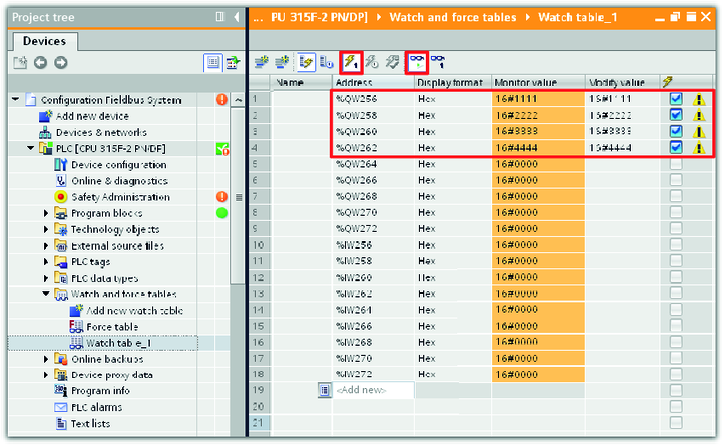

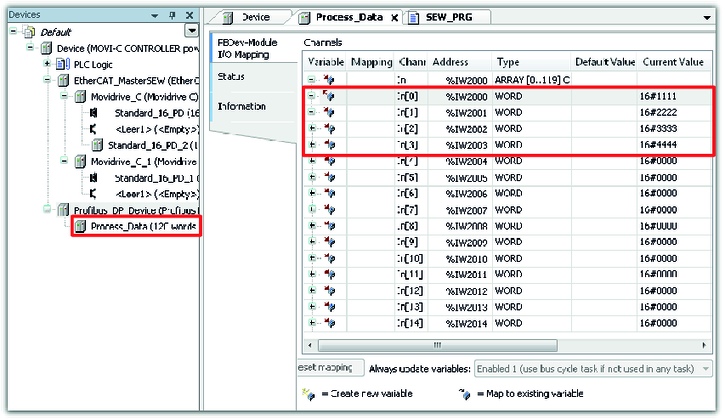

- Checking the process data communication

Additional information