Installing EI7. – DRN../DRU../DR2..71 – 132S motors

Before installation, the grommet [1526] with part number 13637339 must be obtained from SEW-EURODRIVE.

The grommet [1526] is also included in the respective retrofit sets and service kits.

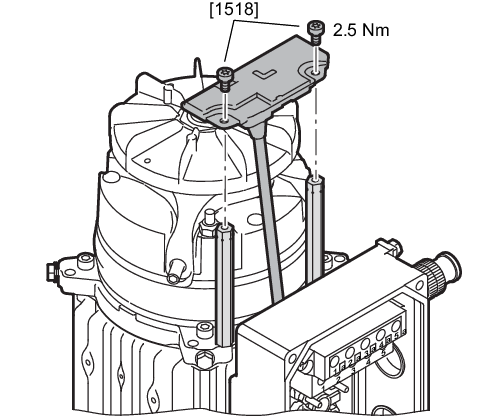

Before installation, the flat-head screws for the brake [1518] with part number 19103387 must be obtained from SEW-EURODRIVE.

The screws [1518] are also included in the respective retrofit sets and service kits.

Before installation, a terminal washer [1524] with part number 13262130 must be obtained from SEW-EURODRIVE.

The terminal washer [1524] is also included in the respective retrofit sets and service kits.

| |

The minimum bending radius of 28 mm must be observed. | |

|

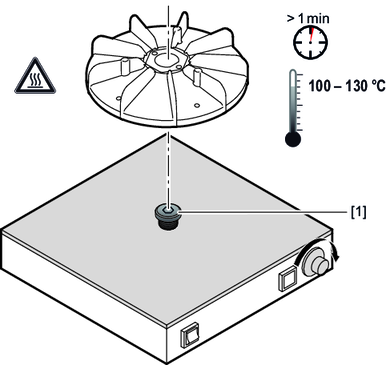

While doing so, ensure that the plastic fan does not come into direct contact with the warming plate. Any thermally conductive component [1] (e.g. a metal ring) can be used as a contact surface. |

| |

| |

| |

|

|