Removing EK8./EK9./AK8./AK9./RK8M – Add-on encoder set A-Box-U for connection option in/on terminal box

NOTICE

Damage to the terminal strip when working below 0 °C

Perform assembly/disassembly work on the terminal strip only at temperatures above 0 °C.

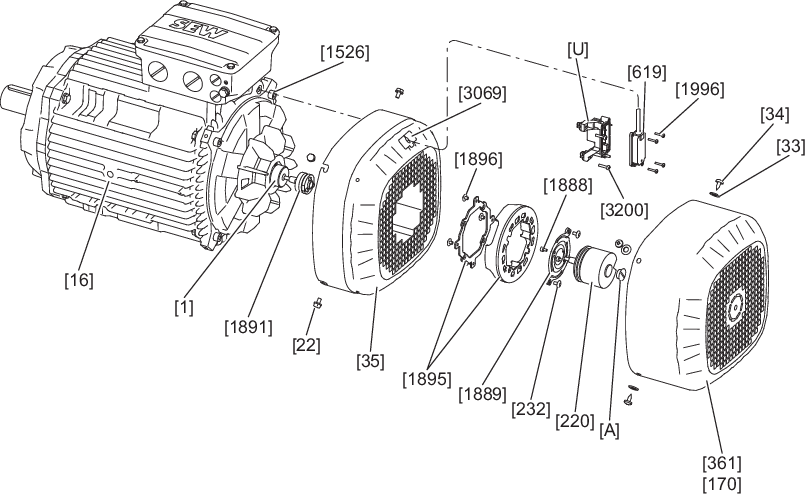

- With forced cooling fan: Unscrew the screws [22].

- Without forced cooling fan: Unscrew the screws [34]/[1711].

- Remove the safety cover [361]/[657] or the forced cooling fan [170] from the motor.

- With forced cooling fan: Remove the signal cable from the 3 wings of the cable retainer [1900].

- For size 80 with brake: Remove the cable tie [3229] that attaches the encoder cable [619] to the fan guard [35].

- Unscrew the screws [1996] and remove the connection cover [1995] from the connection unit [U].

- Without forced cooling fan: Loosen the screws [3200] on the connection unit [U] and then remove the connection unit [U] from the central grille of the fan guard [35].

- For size 132M – 180 with forced cooling fan: Remove the screws [3188] with which the connection unit [U] is screwed to the torque bracket.

- Unscrew the screws [232].

- Remove the fan guard [35] over the encoder [220]. Guide the connection unit [U] with the signal cable through the cutout of the fan guard [35].

- For size 132M – 180 with forced cooling fan: Remove the screw [936] or the nut [734], the spacer bushing [934], and the torque bracket [935].

- Perform a new adjustment.

- Unscrew the screw plug [A] of the encoder [220].

- Loosen the central retaining screw of the encoder [220]. Use a tool that is at least 45 mm long for this.

- If the central retaining screw of the encoder [220] cannot be loosened, counter-tighten the spanner flat SW10 of the encoder shaft.

- Loosen the cone connection.

- Encoder EK8., AK8W, AK8Y, RK8M: To loosen the cone connection, continue turning the central retaining screw of the encoder [220] counterclockwise.

- Encoder AK8H: Continue turning the central retaining screw of the encoder [220] counterclockwise. To loosen the conical connection, screw an M6 screw (≥ 70 mm long) into the bore.

- Remove the encoder [220] from the rotor [1] or from the coupling [233]/[1891].

NOTICE