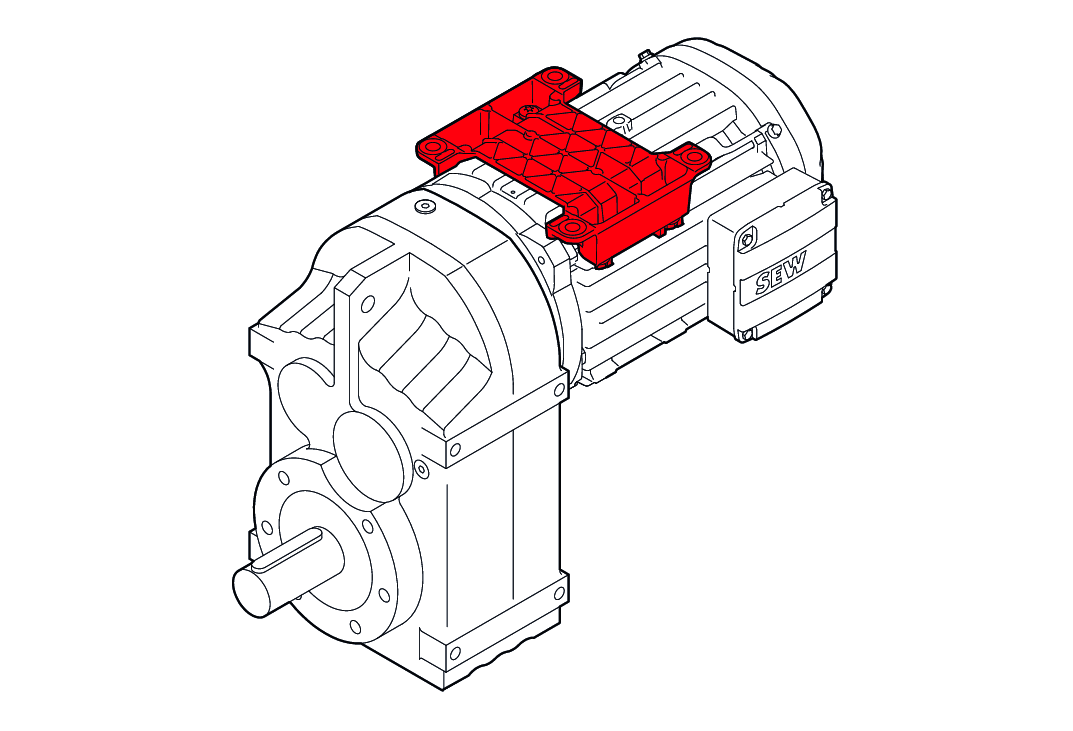

The gearmotors

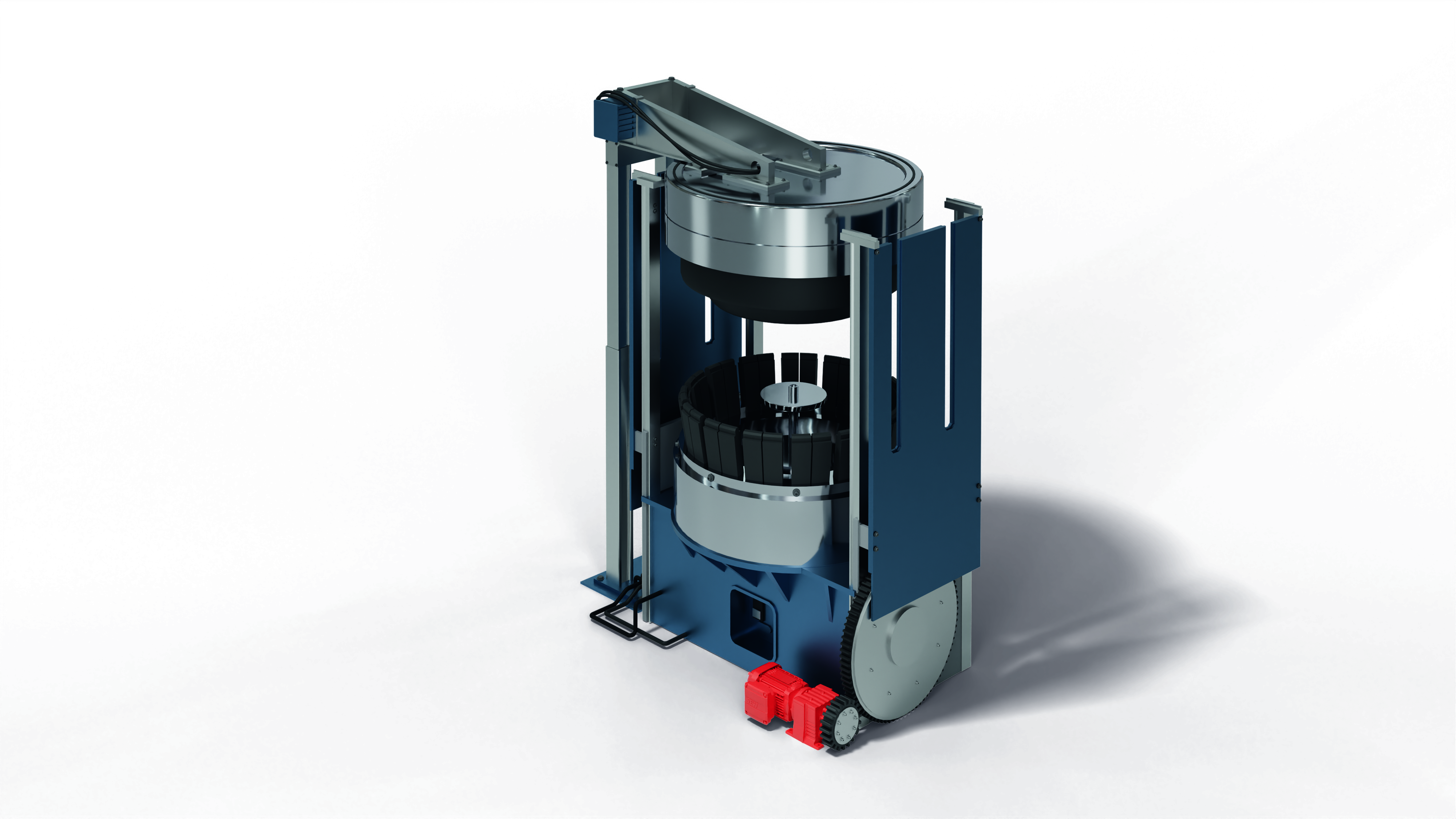

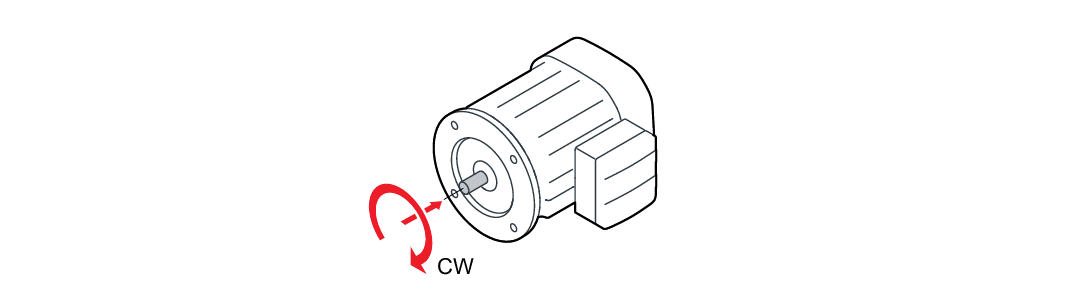

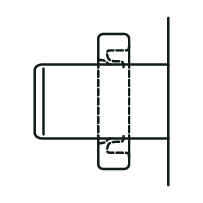

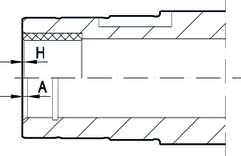

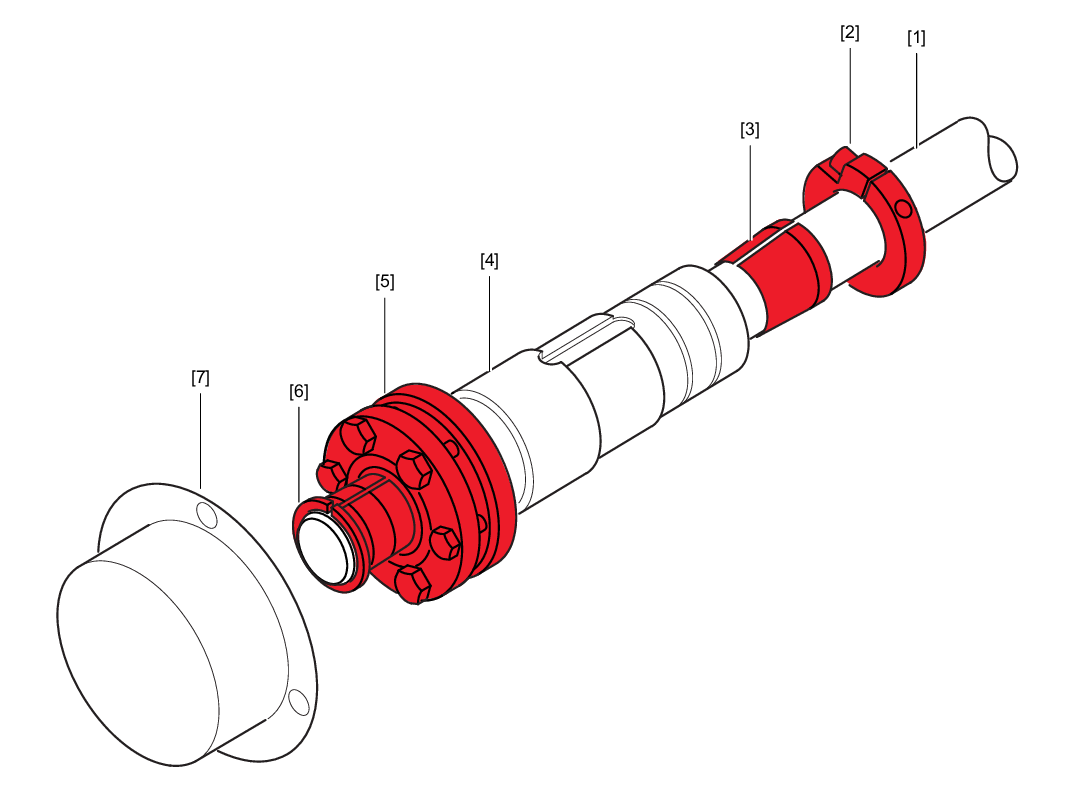

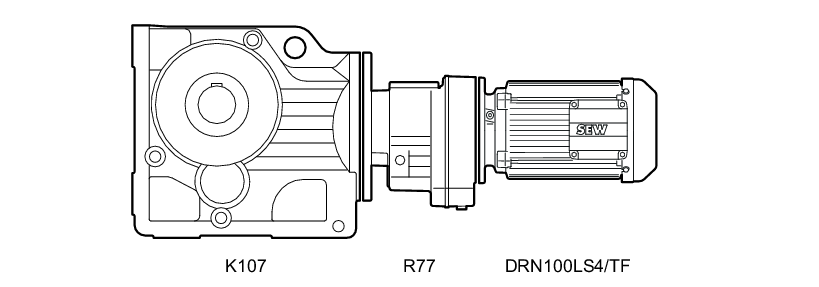

A gearmotor is a homogeneous and compact unit consisting of a gear unit and a motor.

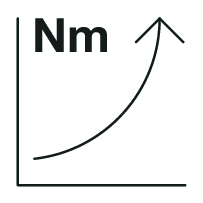

The central role in the gearmotor is performed by the gear unit and its gear unit stages, the gear pairs. These features transmit the force of the motor from the input end to the output end. The gear unit therefore functions as a converter of speed and torque.

In most application cases, the gear unit slows down the rotational speed of the motor while at the same time transmitting significantly higher torques than the electric motor alone could provide. With that in mind, the design of the gear unit determines whether a gearmotor is suitable for light, medium or heavy loads and for short or long power-applied hours.

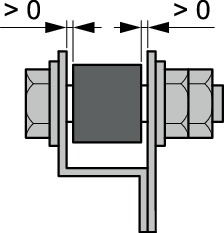

We refer to a reduction ratio or gear ratio based on whether a gear unit steps down or steps up the incoming speed from the motor. The speed ratio i between the input speed and output speed of the gear unit serves as a measure of this.

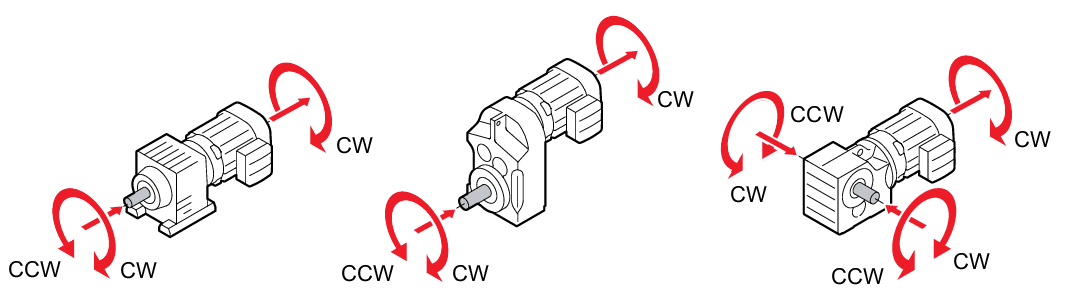

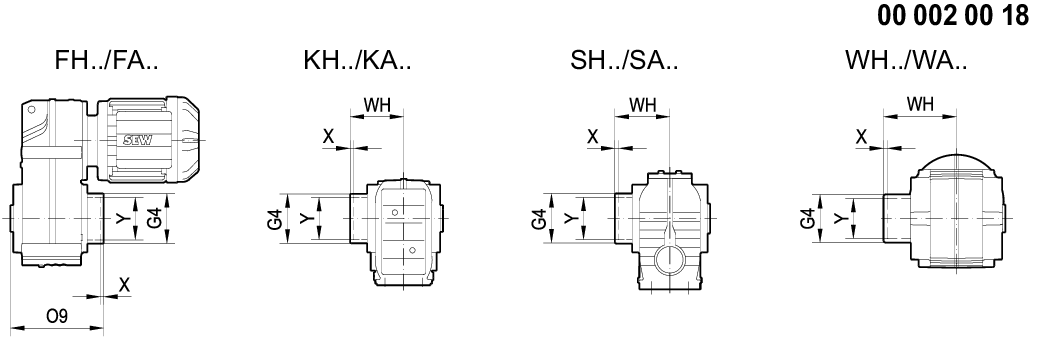

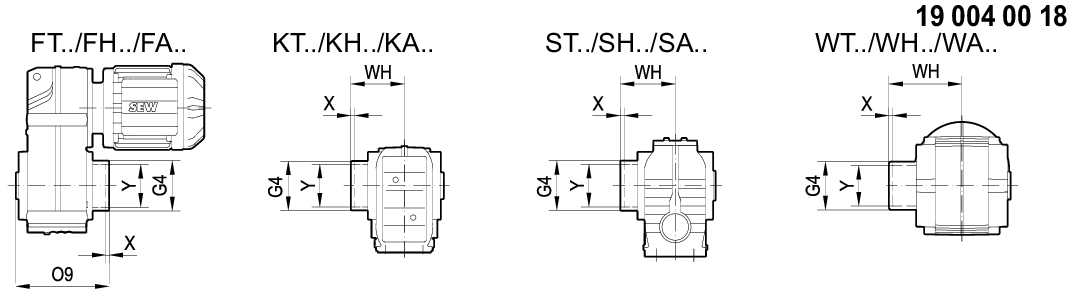

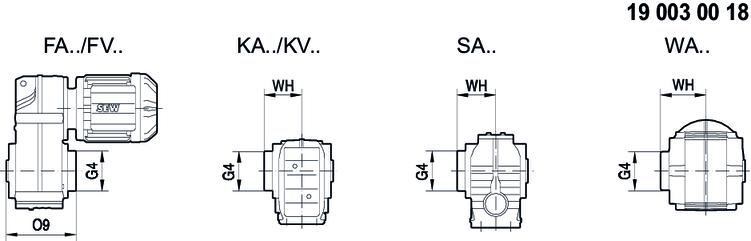

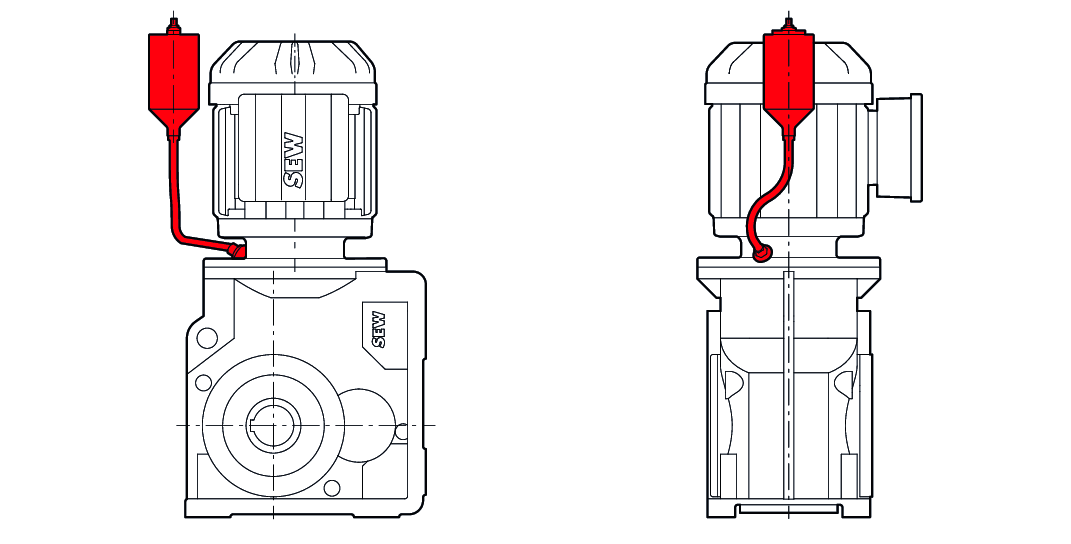

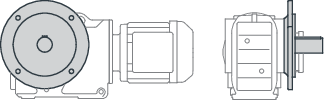

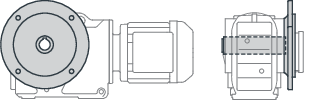

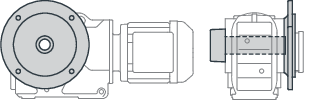

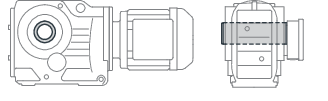

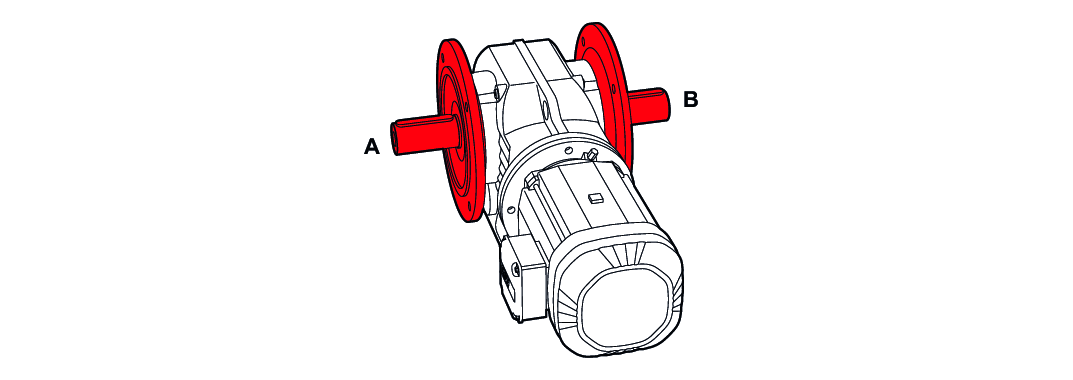

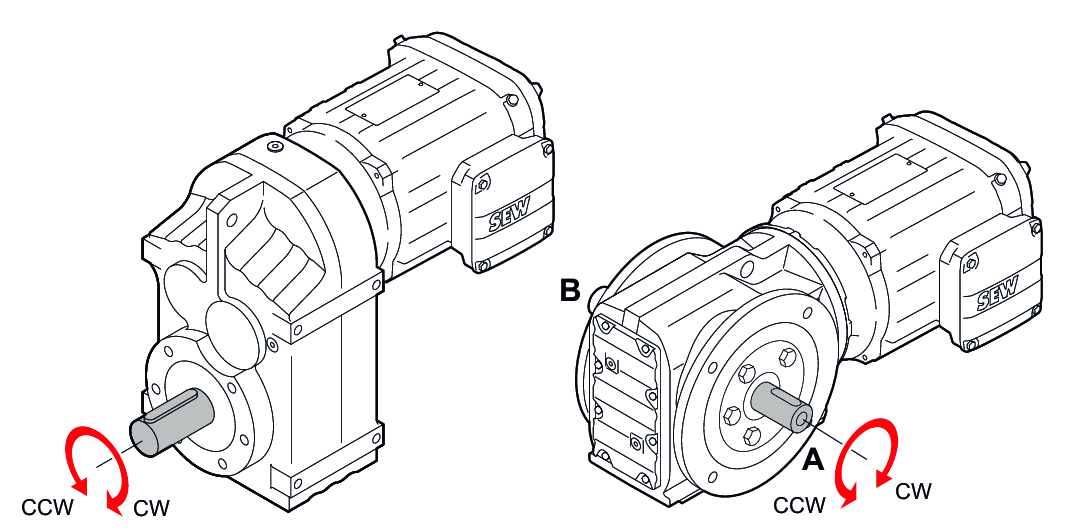

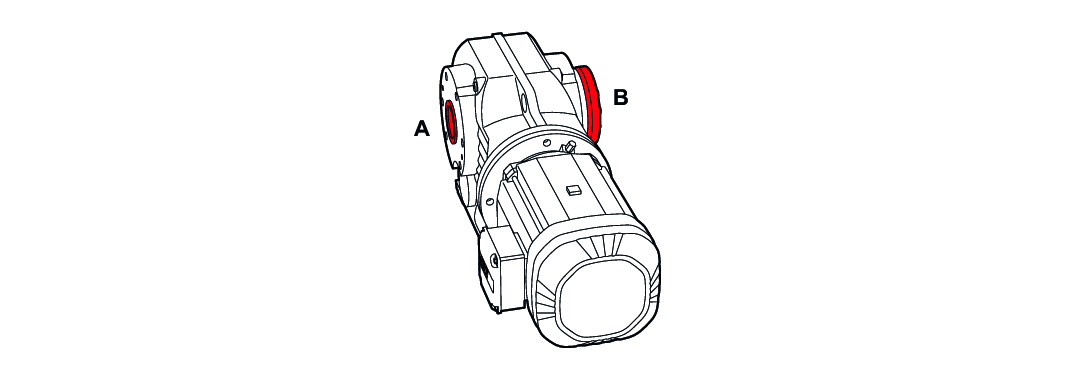

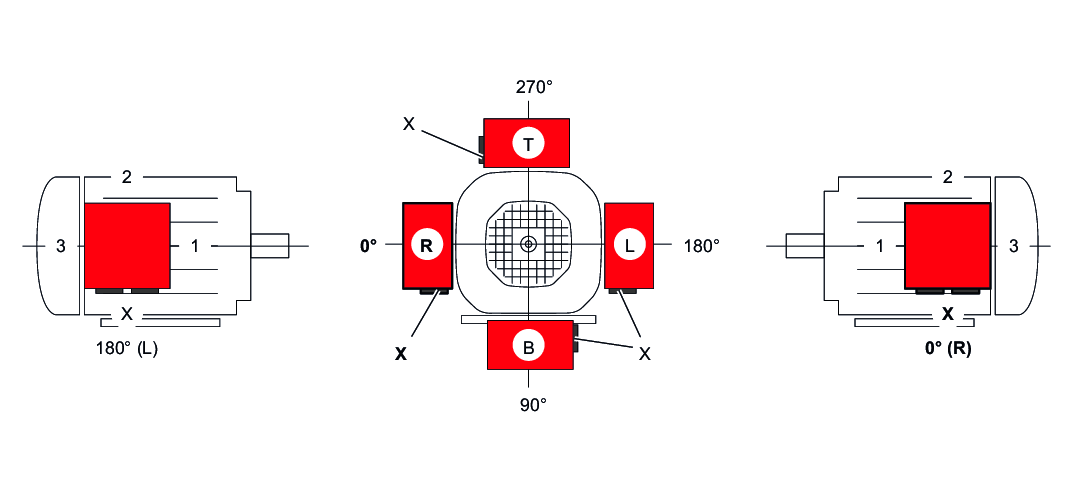

The primary factor in determining the type of gearmotor is the direction of flow force of the gear unit. Here, a distinction is made between the following basic designs:

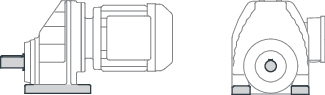

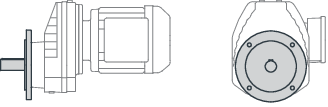

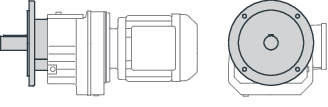

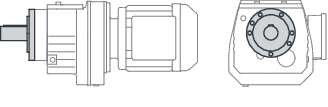

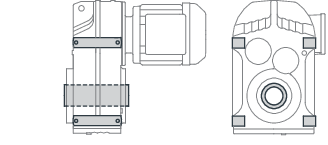

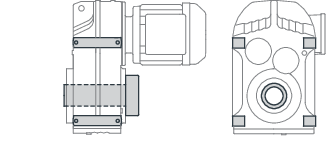

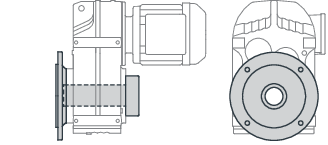

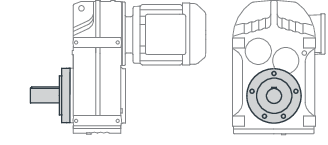

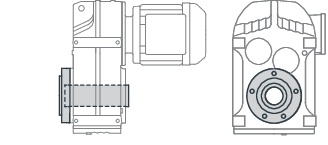

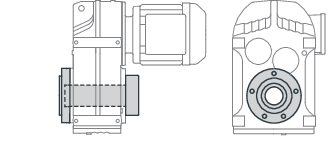

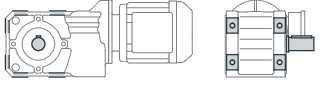

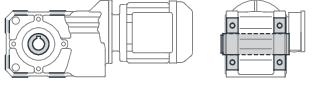

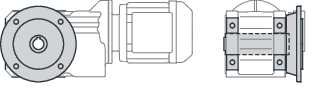

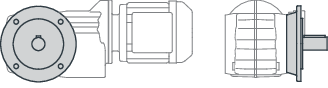

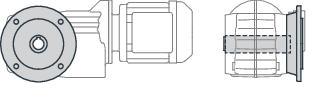

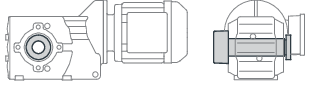

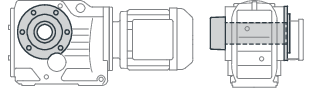

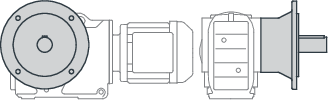

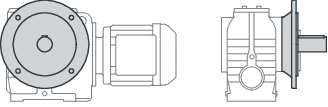

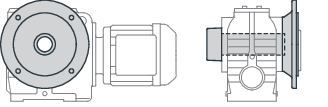

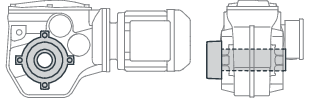

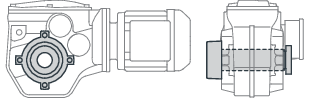

Parallel-shaft gear units

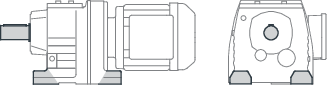

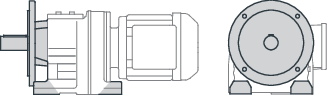

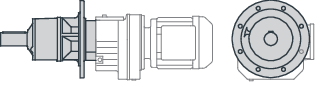

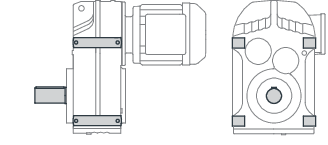

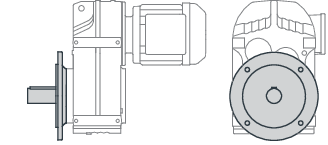

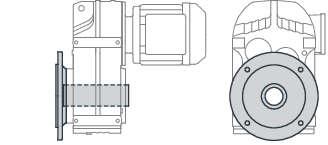

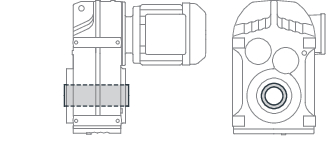

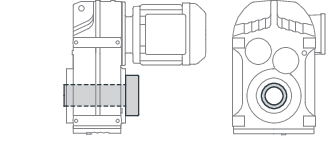

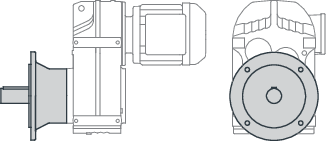

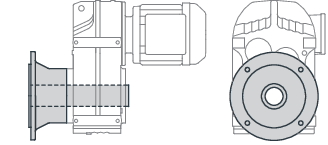

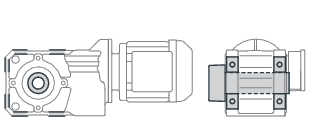

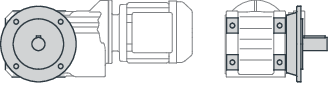

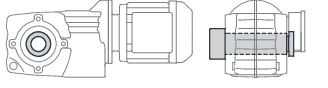

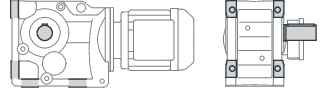

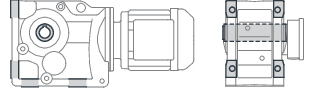

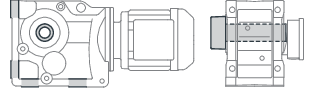

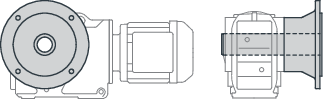

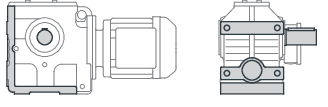

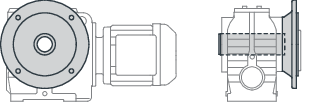

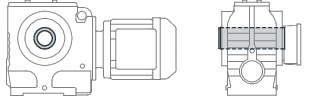

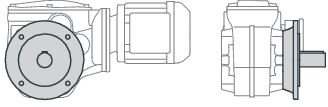

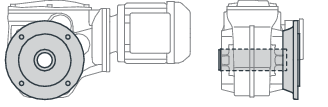

Right-angle gear units

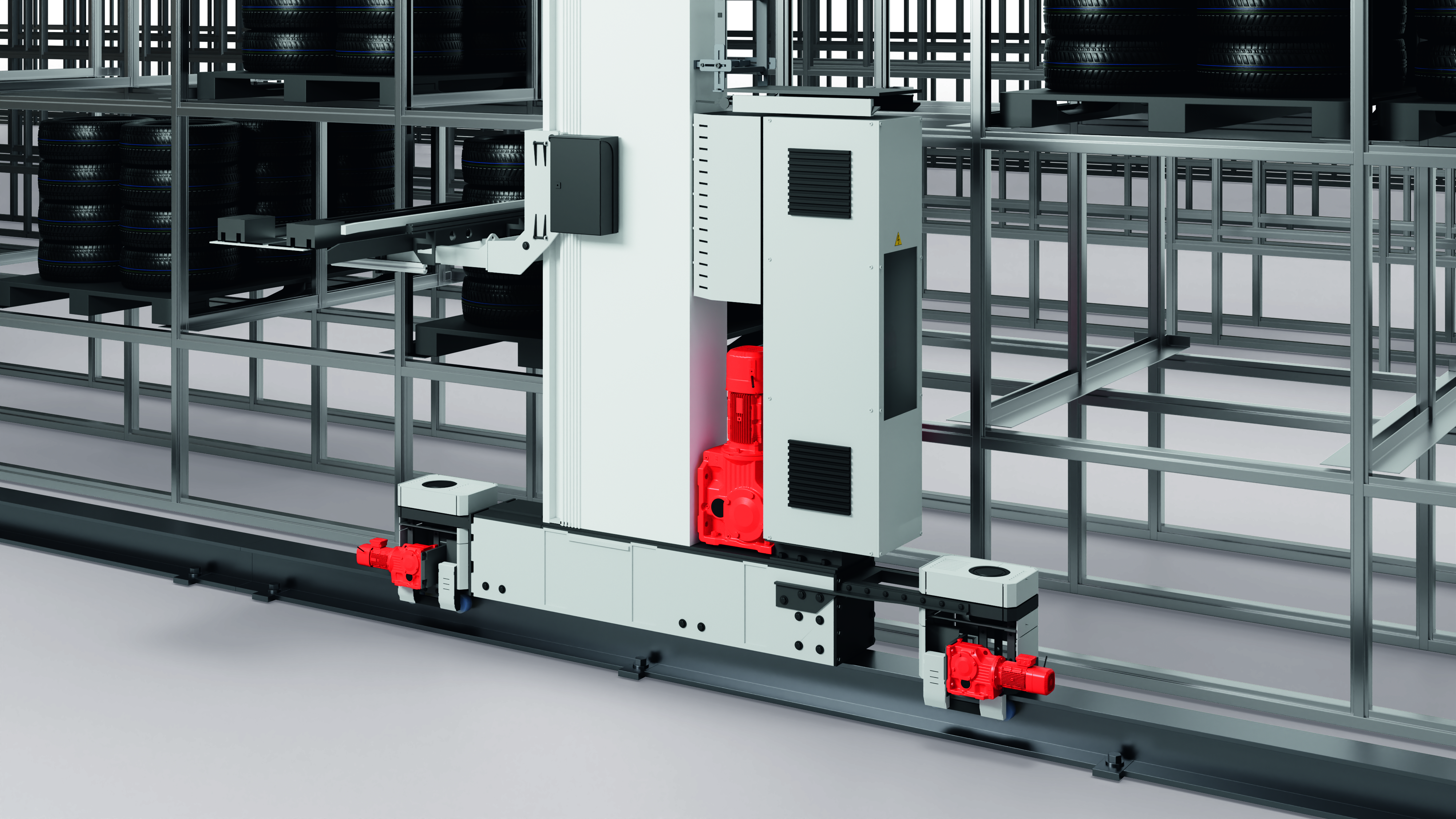

The possible applications for gearmotors are exceptionally varied. Without gearmotors, the entire global economy would come to a standstill. In industrial production, they drive a countless number of conveyor lines, lift and lower loads, and move the widest variety of different goods from A to B in all types of systems.