Shaft-mounted gear unit with TorqLOC® (customer shaft without contact shoulder)

Mount the drive unit on the shaft as follows:

- Perform the steps according to the chapter Installation notes.

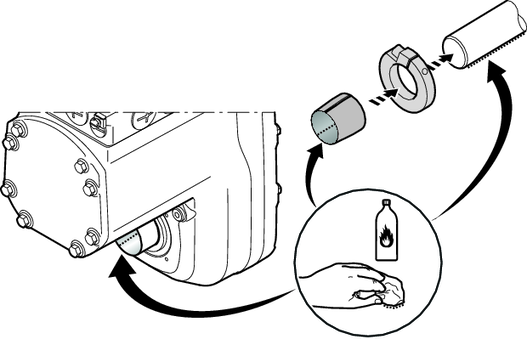

- Clean the customer shaft and the inside of the hollow shaft. Make sure that all grease and oil residues are removed.

- Mount the stop ring and the bushing on the customer shaft.

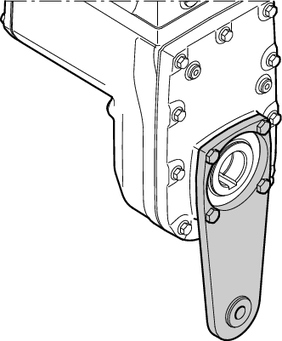

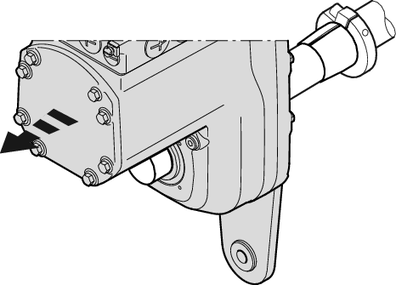

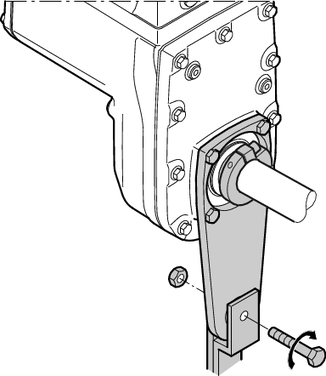

- Attach the torque arm to the drive unit. Observe chapter Torque arm. Installation of the drive unit without a torque arm is not permitted.

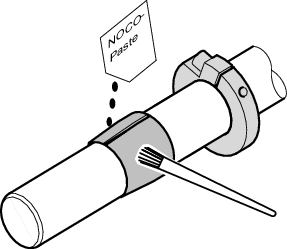

- Apply NOCO-Paste onto the bushing and spread it carefully.

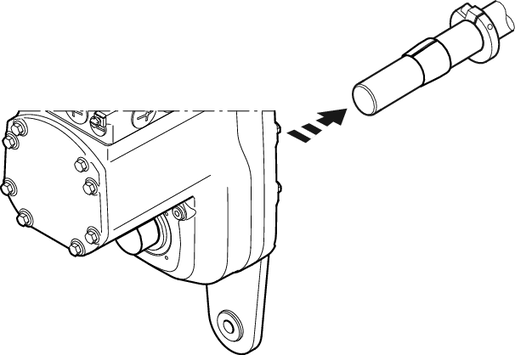

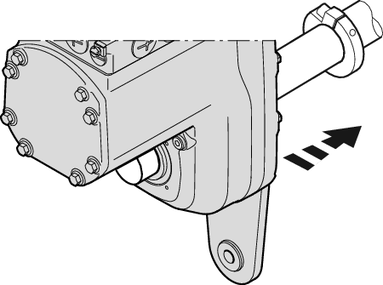

- Slide the gear unit onto the customer shaft.

- Mount the torque arm onto the system structure/holding fixture (do not tighten the screws).

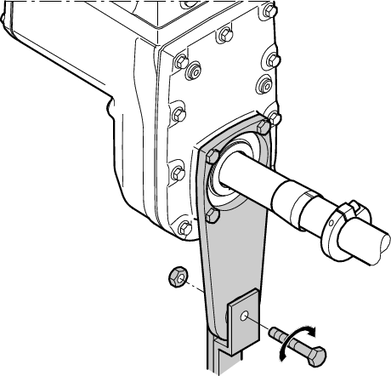

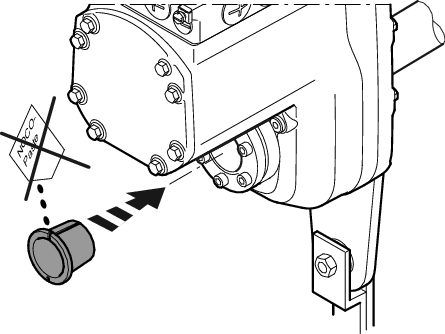

- Slide the bushing into the gear unit as far as its stop.

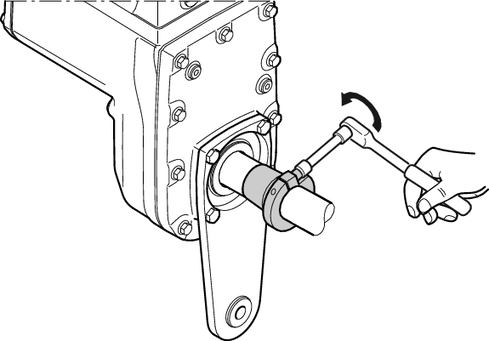

- Slide the stop ring onto the bushing. Mark the position of the stop ring.

- Remove the torque arm from the holding fixture/system structure.

- Remove the gear unit from the customer shaft until the stop ring is accessible for installation.

- Make sure that the position of the stop ring has not changed (note the marking).

- Tighten the stop ring with the following torque:

- Standard design: 18 Nm

- Stainless steel: 7.5 Nm

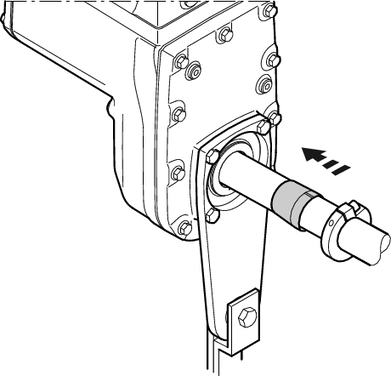

- Slide the bushing and the gear unit onto the customer shaft up to the fixed stop ring.

- Mount the torque arm onto the system structure/holding fixture again (do not tighten the screws).

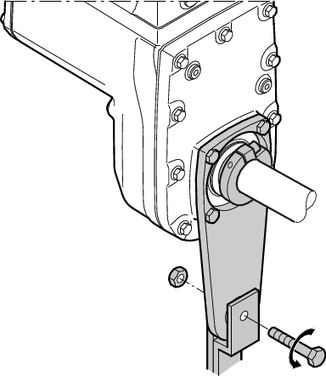

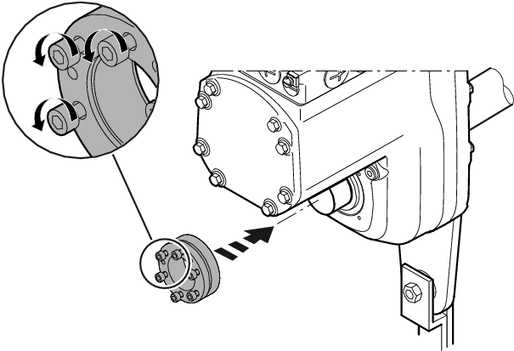

- Make sure that all screws are loosened and slide the shrink disk onto the hollow shaft.

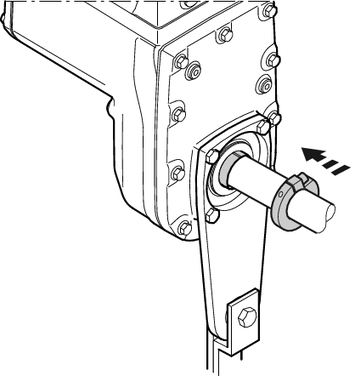

- Slide the counter bushing onto the customer shaft and into the hollow shaft.

- In the case of a gear unit with shaft shoulder, mount the shrink disk at the shaft shoulder up to the stop. In the case of a gear unit without shaft shoulder, mount the shrink disk at a distance of 6.5 mm to 7.5 mm from the gear unit housing.

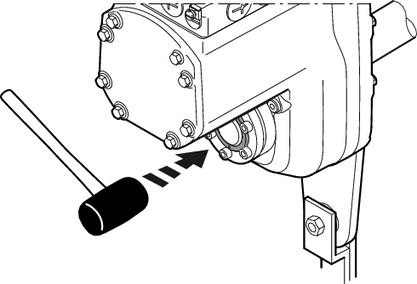

- Lightly hammer on the flange of the counter bushing to ensure that the bushing is firmly seated in the hollow shaft.

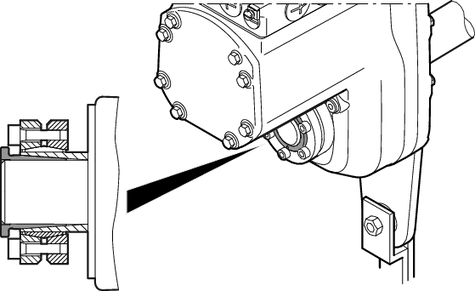

- Make sure that the customer shaft is seated in the counter bushing.

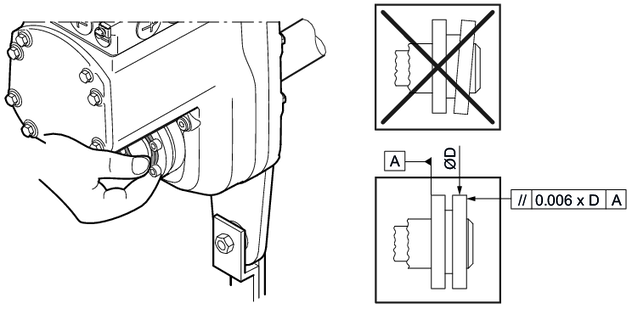

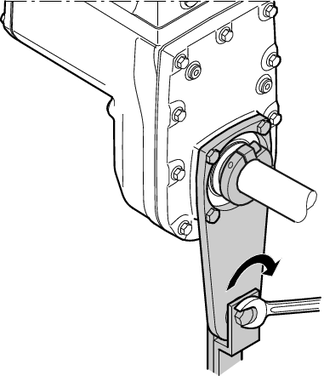

- Tighten the screws of the shrink disk only hand-tight and make sure that the outer rings of the shrink disk are plane-parallel.

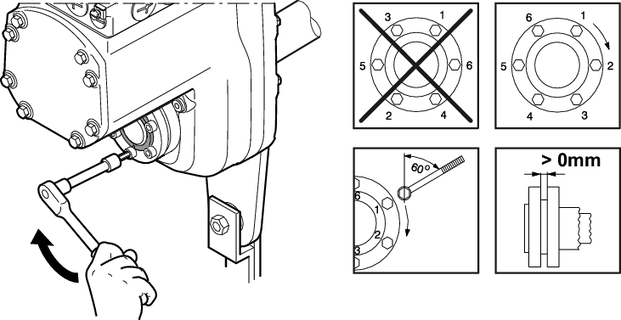

- Tighten the locking screws by working round several times from one screw to the next (not in diametrically opposite sequence):

- The exact values for the tightening torques are located on the shrink disk.

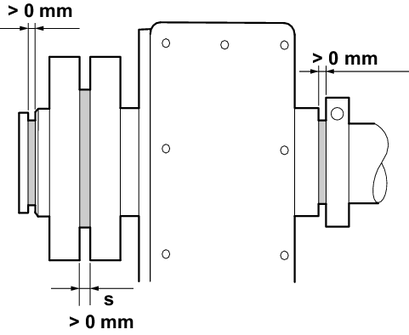

- After installation, make sure the remaining gap s between the outer rings of the shrink disks is > 0 mm.

- The remaining gap between the counter bushing and hollow shaft end, as well as the bushing and stop ring must be > 0 mm.

- Tighten the torque arm sufficiently. Observe chapter Torque arm.