Connecting the MOVI‑C® CONTROLLER to a Modbus TCP network

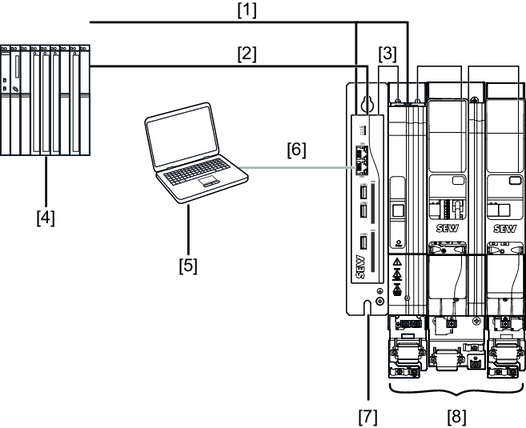

The following device topology is used in the example:

- Higher-level Modbus TCP master

- MOVIDRIVE® modular application inverter, MDD90A double-axis module

- MOVIDRIVE® modular application inverter, MDA90A single-axis module

The following figure is a schematic representation of the device topology:

[1] | DC 24 V supply voltage |

[2] | Connection to Modbus TCP |

[3] | EtherCAT®/SBusPLUS connection |

[4] | Modbus TCP master |

[5] | Engineering PC |

[6] | Connection to engineering interface X80 |

[7] | MOVI-C® CONTROLLER progressive UHX65A-R |

[8] | MOVIDRIVE® modular axis system |

For configuration and startup of the devices, the following tools are used:

- MOVISUITE® for the devices of the MOVI‑C® modular automation system from SEW‑EURODRIVE

- MOVISUITE® contains the IEC Editor tool for programming the MOVI‑C® CONTROLLER.

- Higher-level Modbus TCP master for the PLC.

The MOVI‑C® CONTROLLER is integrated into the Modbus TCP network in several process steps:

- Configuration of the EtherCAT®/SBusPLUS stations

- Integrate the higher-level Modbus TCP master into the Modbus TCP network

- Checking the process data transfer