Recommended procedure for diagnostics

It is useful to divide the error causes into several categories to allow for fast and accurate diagnostics:

- Software errors, for example:

- Slave not configured correctly in the IEC Editor: e.g. configuration of basic functions or of process data.

- Faulty processing of process data.

- Synchronization loss.

- Hardware errors, for example:

- Connection is interrupted between individual stations in the network, e.g. caused by a broken cable or loose contact.

- EMC problems in the plant.

- Malfunctions or voltage failure in the slaves.

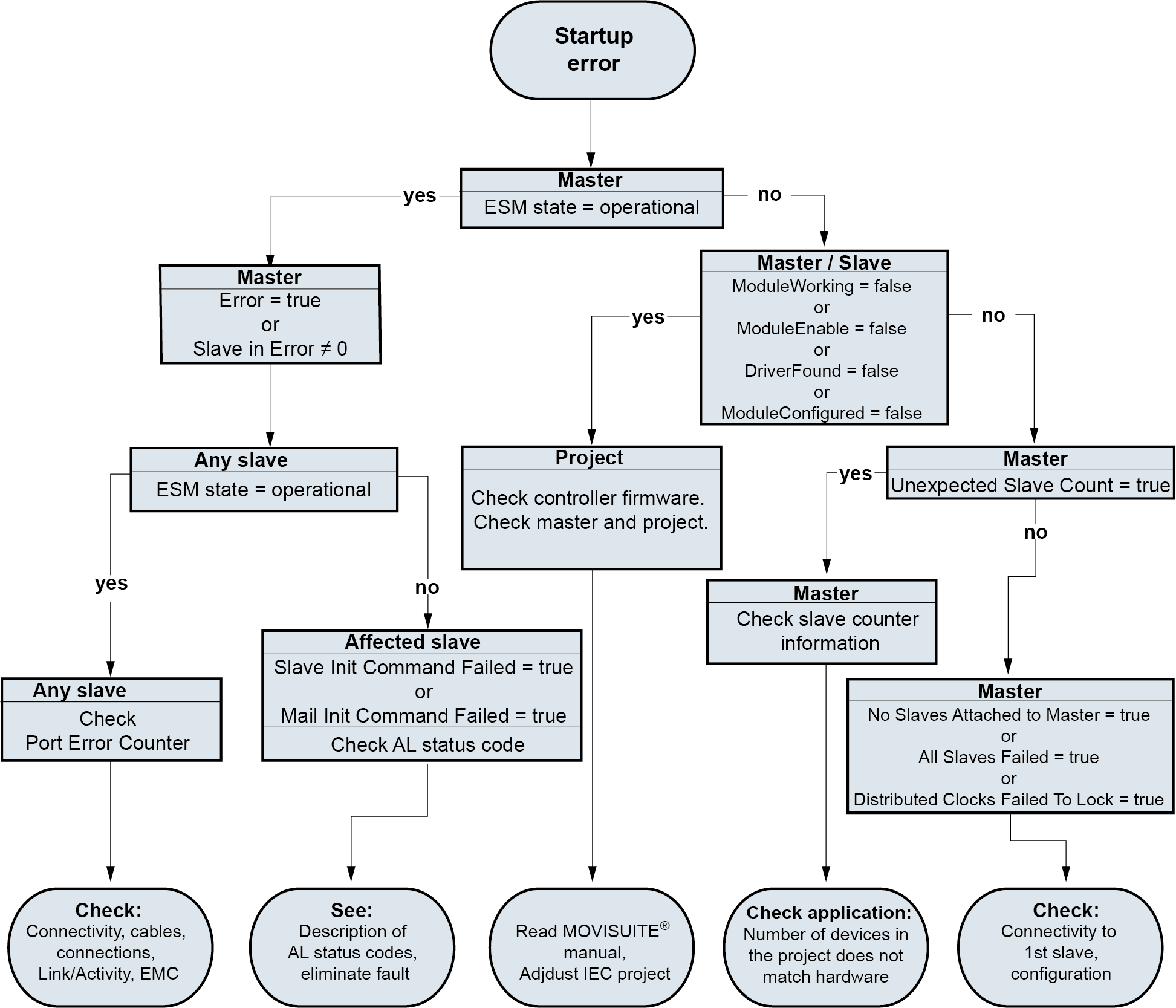

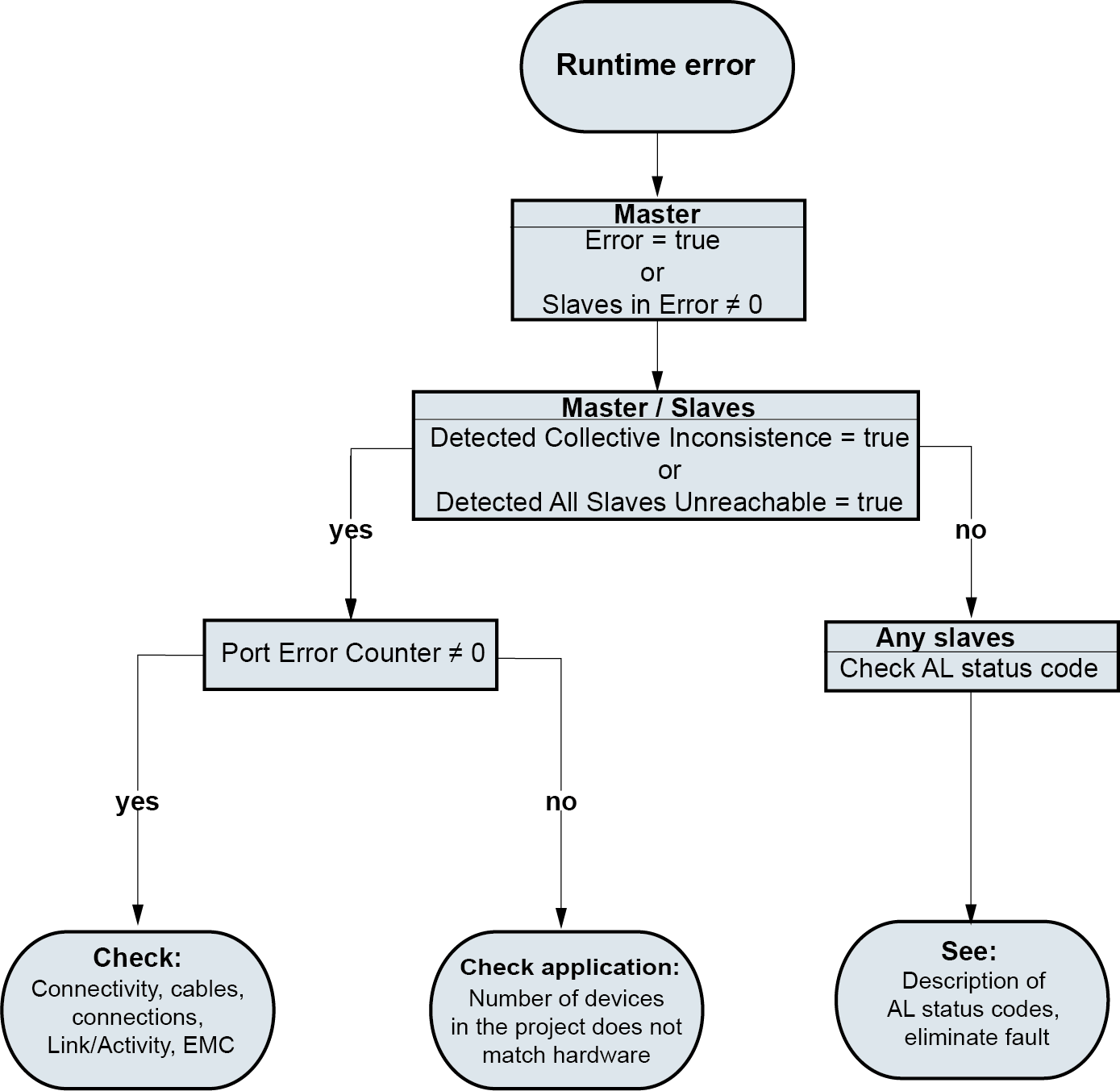

The following diagram provides support in troubleshooting. A distinction is made between errors that occurred during startup and errors that occurred during runtime: