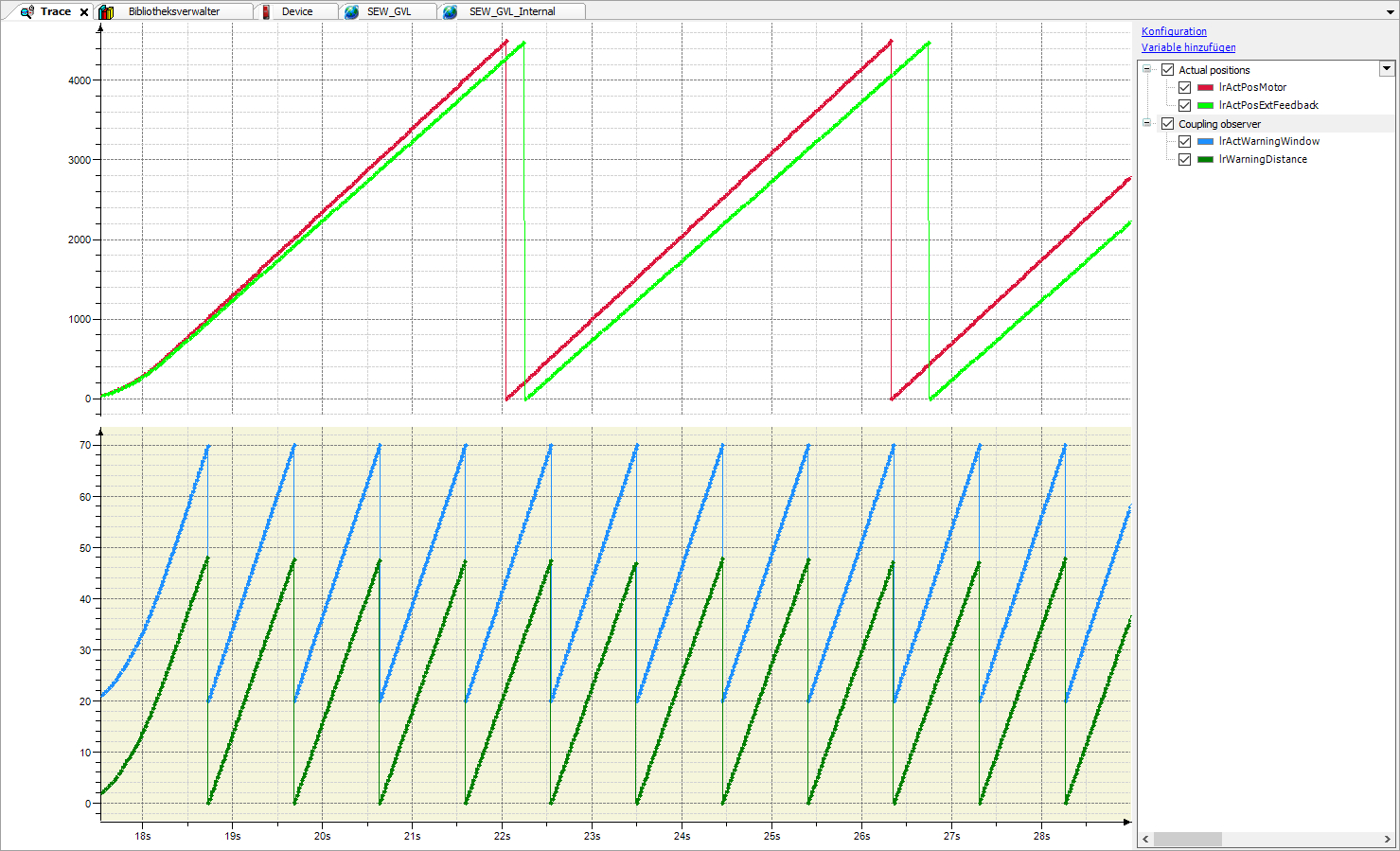

Application example (trace recording)

In the following trace recording, a frictional encoder coupling with modulo is shown in which, for example, the drive wheel is slightly worn and the motor encoder [red] covers more distance as a result. The slip period is configured to be equal to the modulo size, so that the slip window calculation is always cleared accordingly after each break.

The value for the current warning window increases according to the configured percentage slippage warning window and the value for the absolute warning window in each slippage period. The current coupling error increases in each slip period due to the incorrect wheel diameter, but the amount does not yet exceed the warning window. If the wheel continues to wear, the current coupling error increases until the warning window is exceeded, so that a warning is output in the log.

Red | Motor encoder (lrActPosMotor) |

Light green | External encoder (lrActPosExtFeedback) |

Light blue | Current warning window (lrActWarningWindow) |

Green | Current coupling error (lrActWarningDistance) |