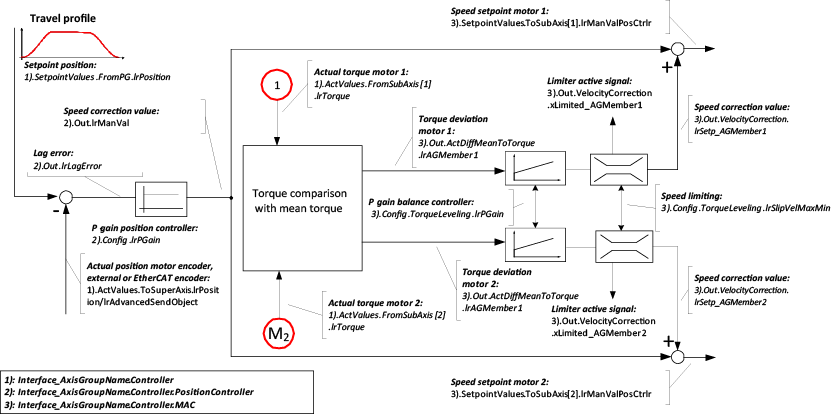

Torque priority

In "Torque priority" operating mode, the torque is balanced between axis group members. This operating mode is used when the connection of the drives allows one drive to exert considerable force on the other drives. These framework conditions apply to connections between drives that have no clearance and a high level of stiffness or rigidity (e.g. traction-optimized vehicles, SRS travel drives, SRS units with cornering ability, fail-safe and redundant drive systems, slippery or poor-quality tracks, and indexing tables).

Application example

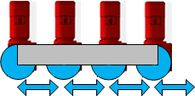

The following application illustration shows an example setup for "Torque priority" operating mode:

One vehicle is moved by 4 drives. The drives are connected to the vehicle via drive suspensions. The floor provides a frictional, rigid connection between the drives. When the drives move synchronously, each axis group member is subject to different loads due to the inhomogeneity of the real system (wheel diameter, friction coefficient, etc). In "Torque priority" operating mode, the software module compensates for this difference in load.

Other applications

The following applications and functions are implemented using this operating mode:

- Torque distribution

- Synchronization with torque distribution

- Load distribution

- Rigid coupling of the drives, formerly "torque slave"

- Load balancing, formerly "master/slave"

- Speed synchronism (turn off position controller and balance controller)

- Torque follower

- Torque decoupling

- Drive tension can be configured online (electronic differential)

- Parameterizable differential lock

- ASR (replaces the generation B ASR software)

- Redundant drive systems by deactivating any axis group member during maintenance.

- Traction-optimization (e.g. in the case of poor-quality tracks or high dynamics)