Skew priority

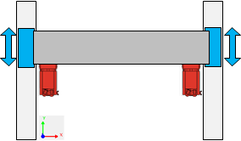

In "Skew priority" operating mode, the position is balanced between axis group members. This operating mode is used when the connection of the drives does not allow one drive to exert force on the other drives, or only to a small extent. These framework conditions apply to connections between drives that have clearance and a low level of stiffness or rigidity (e.g. dual-column hoists, SRS hoists, indoor cranes, and parallel feeds).

Application example

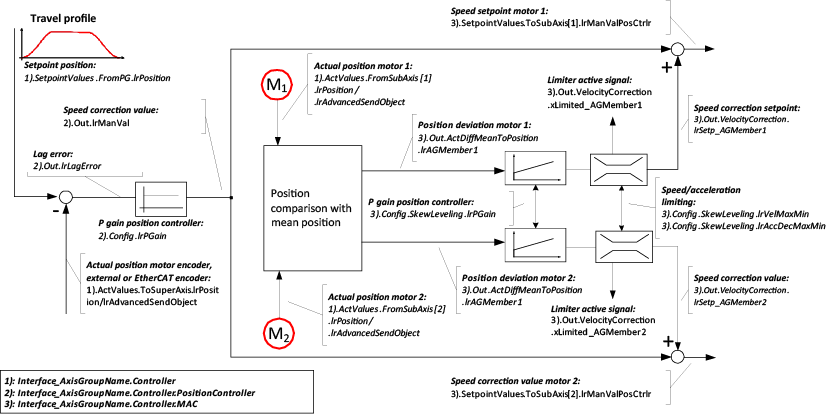

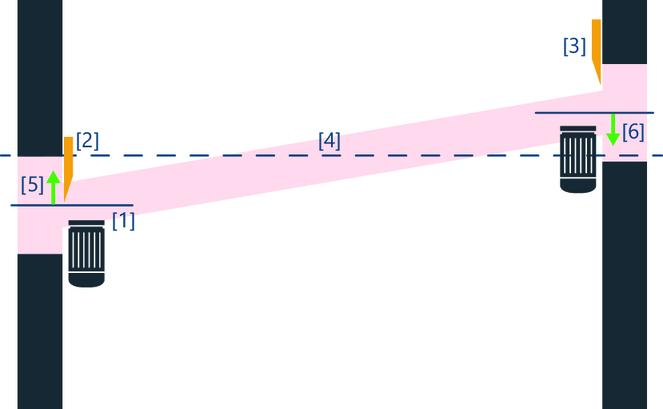

The following application illustration shows an example setup for "Skew priority" operating mode:

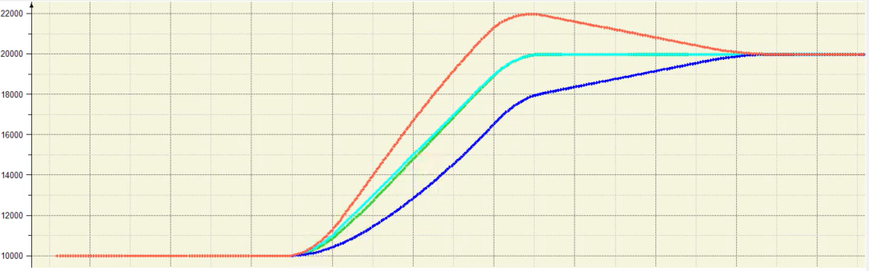

One vehicle is moved by 2 drives that are connected to the vehicle via drive suspension. Guide rails provide a rigid connection between the drives. To establish a fixed reference between the drive position and its surroundings, the guide rails are designed in the form of a toothed rail or equipped with an external encoder. In such structures, skews or misalignments between axis group members may cause damage. This is why the position between both sides should be balanced. In "Skew priority" operating mode, the software module compensates for positional differences (e.g. due to drive overload, slipping of a drive, freewheel of a drive, etc.) by using a configurable compensation movement.

Other applications

The following applications and functions are implemented using this operating mode:

- Phase-synchronous operation

- Speed synchronism (turn off position controller and balance controller)

- Loosely coupled drives

- Alignment function can be used continuously

- Overload guard: prevents asynchronicity in the event of an accident

- Master/slave synchronous operation (1:1 gear ratio)

- Double spindle drives that tilt or jam quickly when in a different position

- FCB 22 Multi-drive

- SyncCrane – Functional replacement (in preparation)

- DriveSync – Functional replacement for a gear ratio of 1:1 (in preparation)