Installing EI8. – DRN../DRU../DR2..71 – 132S motors, with connection unit

Before installation, the centering ring [1920] with part number 22659129 must be obtained from SEW-EURODRIVE.

The centering ring [1920] is also included in the respective retrofit sets and service kits.

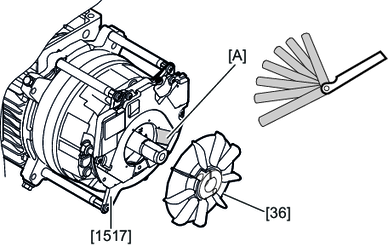

- Required resources: Feeler gauge (0.9 mm), screwdriver, centering ring [1920]

- Unscrew the screws [123] to remove the terminal box cover [132].

- Break open the knock-out [K] by using a chisel or screwdriver.

- Pull the grommet [1526] with encoder cable through the knock-out [K].

- The grommet must engage into the opening of the knock-out [K].

- If necessary, screw the hexagonal spacers [1520] into the brake endshield.

- Tightening torque 5 Nm

- Place the centering ring [1920] onto the pole ring.

- Push the encoder module [1517] onto the shaft end.

- Push the fan [36] with bushing and pole ring onto the shaft end.

- Center the encoder module [1517] with the centering ring [1920] radially to the shaft.

- Fasten the encoder module [1517] with 3 screws [1518] on the rear endshield or, if applicable, using 3 screws [1518] on the hexagonal spacers [1520] that are fastened to the brake endshield.

- Tightening torque 2.5 Nm

- Remove the fan [36] with bushing and pole ring from the shaft end and remove the centering ring [1920].

- Push the fan [36] with bushing and pole ring onto the shaft end.

- To set a clear span of 0.9 mm between the pole ring surface and the base of the notch, insert a 0.9 mm feeler gauge into the notch [A].

- Tighten the clamping screw [1160].

- DR..71 – 100: Tightening torque 1.2 Nm

- DR..112 – 132S: Tightening torque 3.3 Nm

- Route the encoder cable in the terminal box in such a way that it is not crushed or improperly subjected to stress.

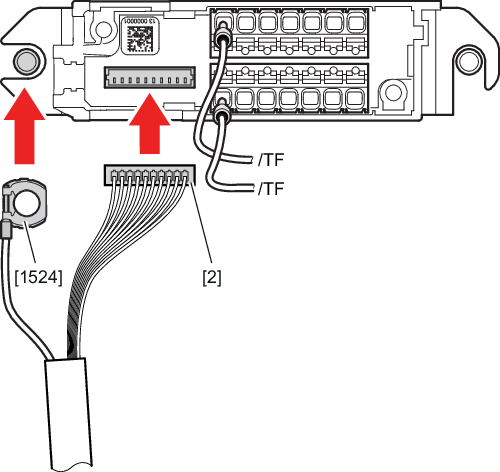

- Remove the cover of the connection unit [1522] by pressing the cover on both sides behind the cable bushing.

- Apply the shielding of the encoder cable onto the terminal washer.

- Place the connection unit [1522] in the terminal box.

- To secure the connection unit [1522] in place, screw the terminal washer [1524] and the shield plate tightly in the terminal box.

- For gray cast iron terminal boxes: Tightening torque 1.8 Nm

- For aluminum terminal boxes: Tightening torque 5 Nm

- Insert the socket contact of the encoder cable [2] onto the connector on the board and insert the encoder cable into the hollow of the connection unit [1522], which serves as strain relief. If applicable, connect the temperature probe /TF.

- Connect the customer's evaluation unit for the encoder to the connection unit [1522] with a shield plate.

- Connect the supply voltage and the signal cables of the encoder module [1517] to the connection unit [1522].

- Attach the cover of the connection unit [1522].

- Check the visual feedback of the status LED for the encoder module [1517].

- LED lights up green: The encoder module [1517] has been installed correctly and you can continue with the assembly process.

- LED lights up red: Switch off the supply voltage. Set the distance of 0.9 mm between the encoder module [1517] and the pole ring again. Switch the supply voltage back on. If the status LED still lights up red, contact the SEW-EURODRIVE Service department.

- Mount the terminal box cover [132] using the screws [123] (4 × M5 SW8).

- Tightening torque 4 Nm

- Mount the fan guard [35] with the screws [22].

- For plastic guard: Tightening torque 2 Nm

- For metal guard: Tightening torque 3.3 Nm

- Mount the forced cooling fan [170] if applicable.