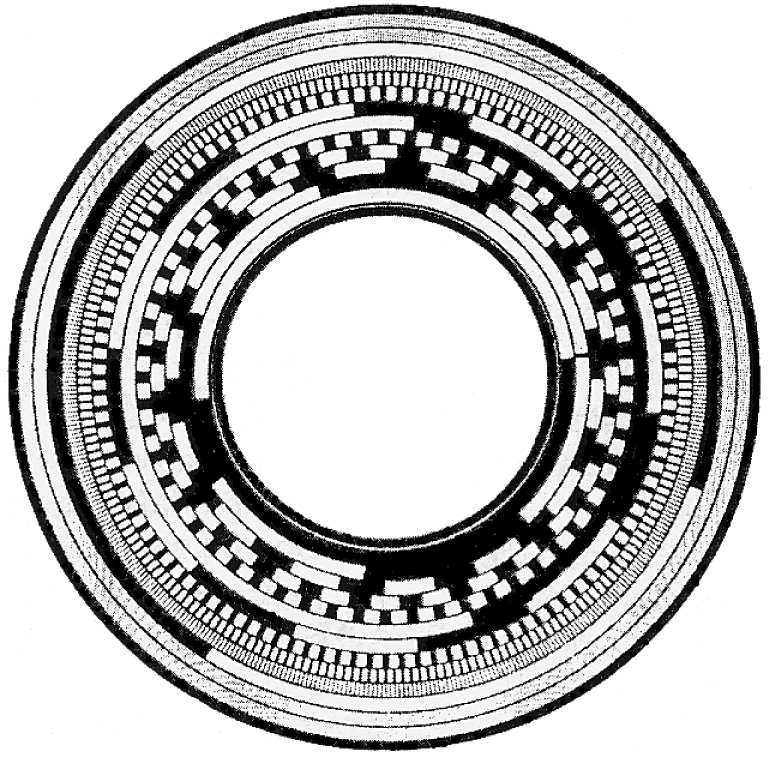

Single-turn encoder

The absolute value information is generated using a code disk, e.g. with Gray code, which is generally scanned optically. Each angle position is assigned a unique code pattern in the process. In this way, it is possible to identify the motor shaft's absolute position. In contrast to binary code, the special feature of a single-step Gray code is that only 1 bit changes at a time, meaning that a faulty scanning process is detected immediately.

Decimal | Gray code | Binary code |

|---|---|---|

0 | 0000 | 0000 |

1 | 0001 | 0001 |

2 | 0011 | 0010 |

3 | 0010 | 0011 |

4 | 0110 | 0100 |

5 | 0111 | 0101 |

6 | 0101 | 0110 |

7 | 0100 | 0111 |

8 | 1100 | 1000 |

9 | 1101 | 1001 |

10 | 1111 | 1010 |

11 | 1110 | 1011 |

12 | 1010 | 1100 |

13 | 1011 | 1101 |

14 | 1001 | 1110 |

15 | 1000 | 1111 |

This encoder design is a so-called single-turn encoder, since the absolute position of the motor shaft can be determined only via a single revolution.