Structure and functional principle

Sin/cos encoders, also known as sine encoders, deliver two sinus signals offset by 90°. During the process, the number and the course of the sinus curves (interpolation and arcus tangent formation) are evaluated. With the help of these values, the rotational speed can be determined with a very high resolution and accuracy. This is particularly advantageous if large setting ranges and low speeds need to be precisely maintained. Furthermore, there is a very high level of control stability.

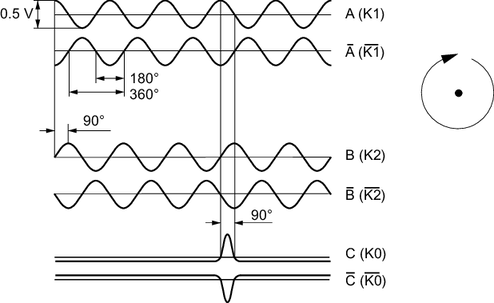

Sin/cos encoders normally have 2 tracks and a zero pulse track. Inverting the signals results in a total of 6 tracks. The 2 signals, which are offset by 90°, are on track A (K1) and B (K2). One sine half wave per revolution is provided at track C (K0) as the zero pulse. The tracks A (K1), B (K2), and C (K0) are inverted in the encoder and provided as inverted signals on tracks A (K1), B (K2) and C (K0).

Track A = cos

Track B = sin