Print mark controller

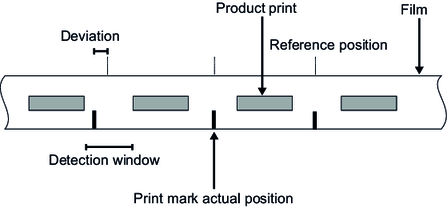

In applications in which the additional function "Print mark controller" is to be used, there are print marks on the material to be processed and there is a print mark sensor in front of the rotary knife. The distance between the sensor and the rotary knife is called the "sensor distance".

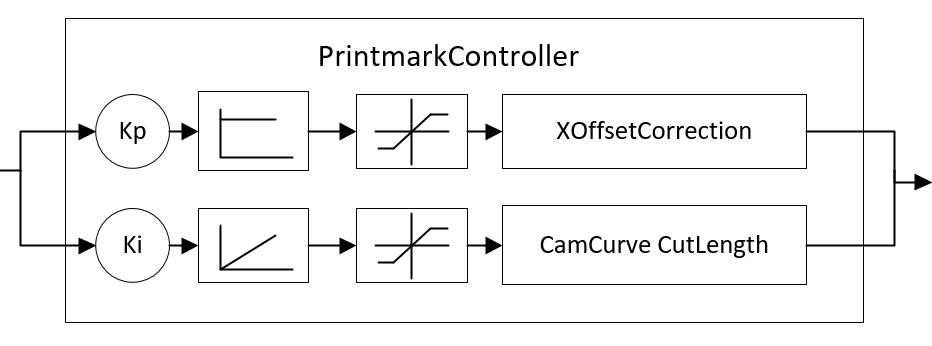

To implement the print mark controller, a proportional correction (X offset correction) and an integrative correction (length of the curve of intersection) are carried out. To calculate the correction, the measured deviation of the print marks are multiplied by the weighting factors "proportional factor" (Kp) and "integrative factor" (Ki) specified in the configuration of the software module in the "Additional functions" > "Print mark controller" configuration menu.

The output of the proportional correction is limited relative to half of the set cut length:

ProportionalCorrectionLimit PLim =

- PLim/100 * ProductLength/2 ≤ Pout ≤ PLim/100 * ProductLength/2

The output of the integrative correction is limited relative to set cut length.

IntegrativeCorrectionLimited ILim =

(1 - ILim/100 * ProductLength ) ≤ Iout ≤ (1 + ILim/100 * ProductLength)