Communication and unit profile

MOVITRAC® B offers digital access to all drive parameters and functions via the communication interfaces.

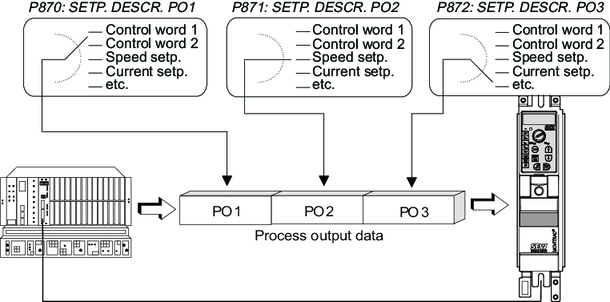

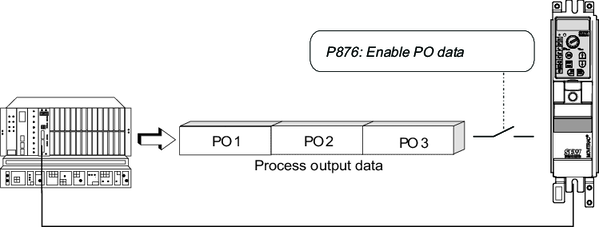

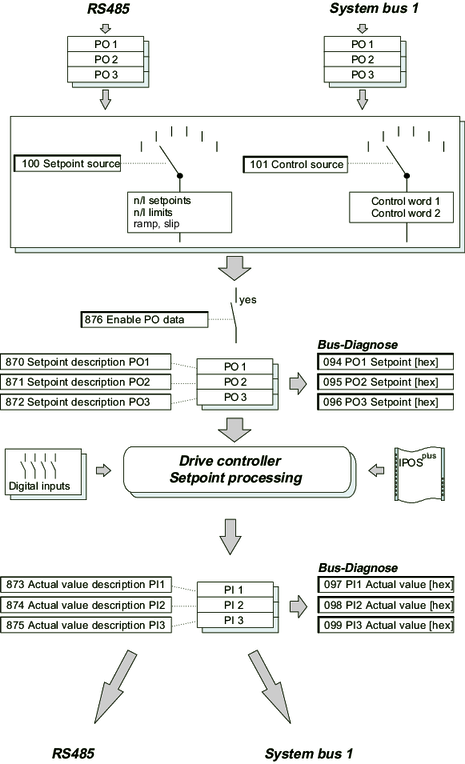

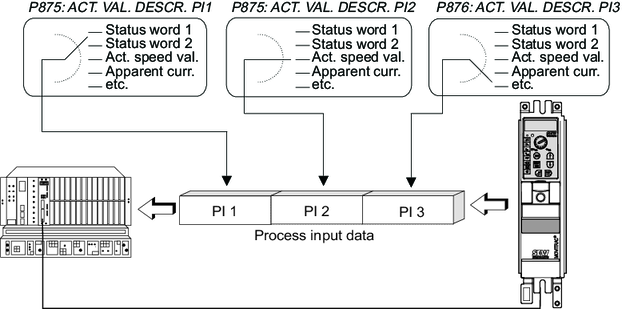

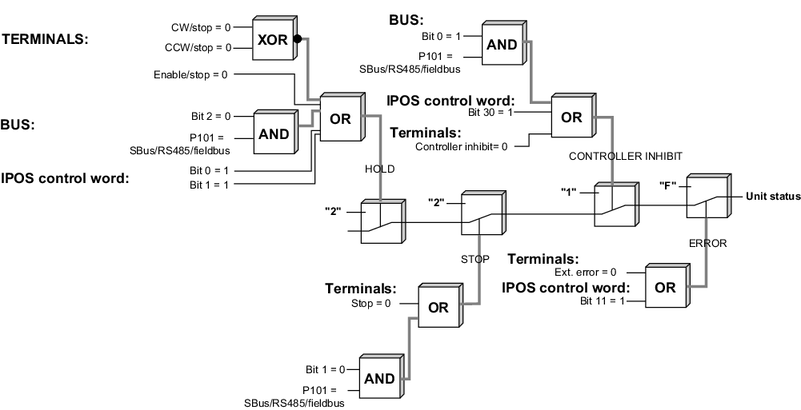

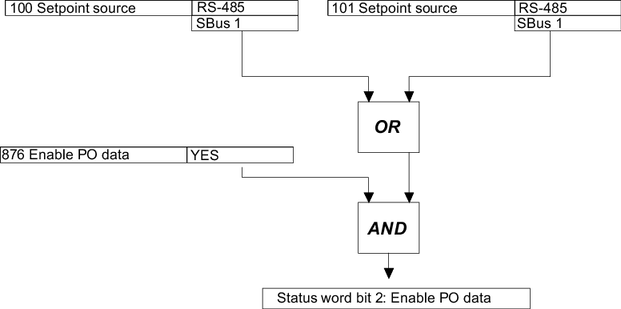

The frequency inverter is controlled via fast, cyclic process data. You can use this process data channel to enter setpoints such as the setpoint speed, ramp generator time for acceleration/deceleration, etc. as well as trigger various drive functions such as enable, control inhibit, normal stop, rapid stop, etc. You can also use this channel to read back actual values from the frequence inverter, such as the actual speed, current, unit status, fault number and reference signals.

In combination with the IPOSplus® positioning and sequence control integrated in the frequency inverter, you can also use the process data channel as direct connection between PLC and IPOSplus®. In this case, the process data are not evaluated by the frequency inverter but directly by the IPOSplus® program.

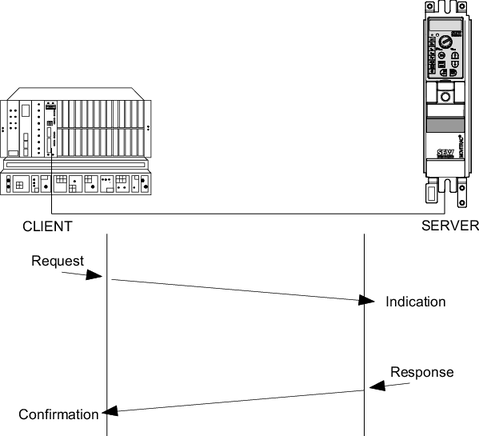

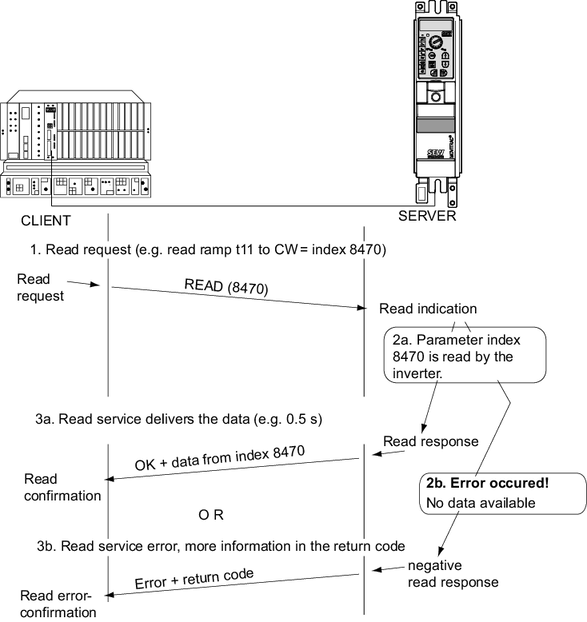

While the process data exchange generally occurs cyclically, the drive parameters can be read or written acyclically using READ and WRITE services. This parameter data exchange enables you to implement applications in which all the important drive parameters are stored in the master programmable controller, so that there is no need to make manual parameter settings on the frequency inverter itself.

The use of a fieldbus system requires additional drive system monitoring such as time monitoring of the fieldbus (fieldbus timeout) or even special emergency stop concepts.

You can customize the monitoring functions of MOVITRAC® B to suit your specific application. You can determine, for instance, which fault response of the frequency inverter should be triggered in the event of a bus error. For many applications, a rapid stop would be the preferred response, but you can also freeze the latest setpoints.

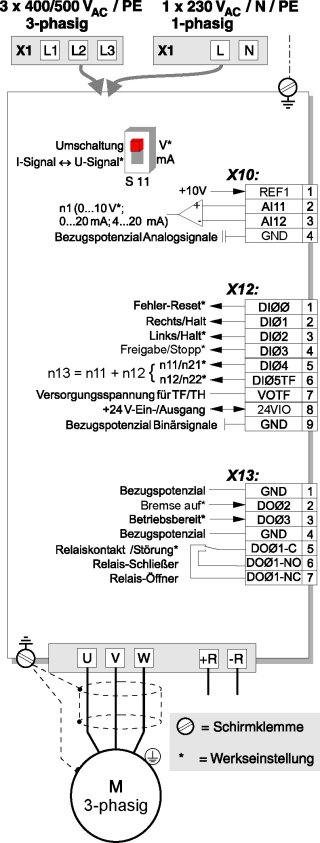

As the functions of the control terminals are still active in fieldbus operation, you can still implement fieldbus-independent emergency stop concepts via the terminals of the frequency inverter.

The MOVITRAC® B inverter offers numerous diagnostic options for startup and service purposes. For example, you can use the DBG60B keypad to control both setpoint values sent from the higher-level controller as well as the actual values. You are also supplied with a variety of additional information about the status of the communication interfaces.

An even more convenient diagnostic option provides the MOVITOOLS® MotionStudio engineering software. It lets you set all drive and communication parameters and displays detailed information of interfaces and unit status.