Inverter selection

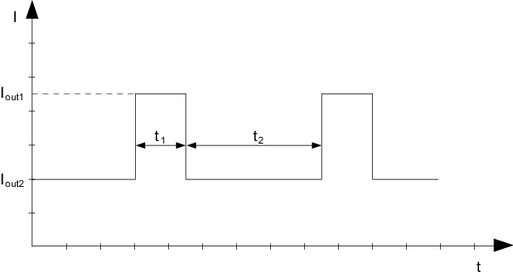

The inverter is selected based on the course of the output current over time. The required current has to be determined from the required torque characteristic of the connected motor.

The inverters are dimensioned for a nominal output current IN. In many applications, there is a demand for short-time overload operation. For this purpose, the inverters can be operated with a higher nominal output current for a short period of time.

For overload operation, make sure that the inverter is not thermally overloaded. For protection of the power components, inverters have various monitoring mechanisms.

The following thermal monitoring functions are available:

- Dynamic utilization

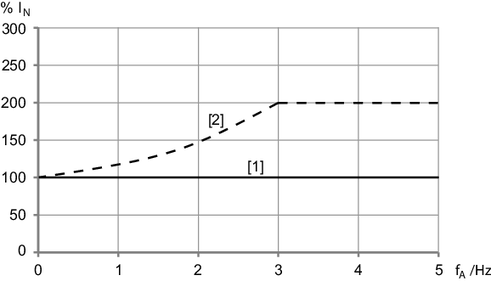

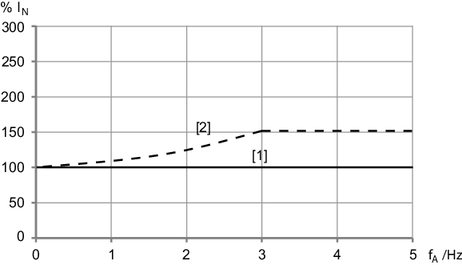

- The periodic current load of the switching power semiconductors lets them heat and cool down cyclically. Due to the different thermal time constants, large temperature differences can occur between power semiconductor and heat sink. Dynamic utilization monitors the permitted temperature of the barrier layer of the power semiconductors.

- Thermal utilization

- The power semiconductors are limited by the maximum permitted temperature during operation. Thermal utilization monitors the heat sink temperature of the power semiconductors.

- Electromechanical utilization (I2t utilization)

- Electromechanical utilization protects the components that have a large thermal time constant compared to the power semiconductors.

Due to the complexity of the utilization curves, the calculation can only be performed using software. The SEW Workbench software offers support for dimensioning an inverter.

For a rough selection of the inverter without using software, characteristic load cycles are provided in the following section.