Equipotential bonding

INFORMATION

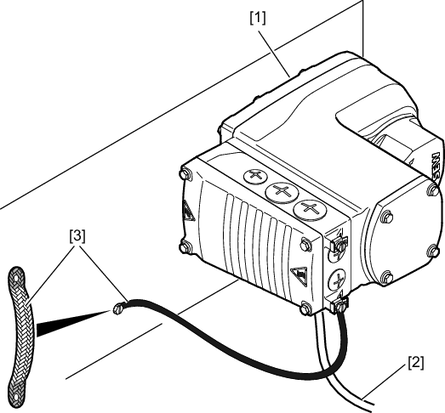

For gearmotors in hollow-shaft design, additional Hf-capable equipotential bonding can be required independent of the mandatory PE connection. For this kind of drive (hollow shaft), high-frequency currents (e.g. by frequency inverters) are not ideally discharged to the system structure.

To minimize and/or prevent EMC interferences, additional Hf-capable equipotential bonding is recommended independent of the PE connection. This applies especially to optionally integrated signal electronics, such as: encoder, "MOVILINK DDI" slave, etc. Equipotential bonding can be implemented by the following alternative measures, for example:

- Shield, connected at both ends, for the motor cable [2].

- EMC-compliant equipotential bonding by highly flexible, fine-stranded PE conductor ≥6 mm² or by a ground strap (HF litz wire) [3]. The contact surfaces must be conductive (free of paint).

[1] | The mechanical installation of a drive unit with hollow shaft does not create a conductive connection of drive unit and mounting plate. |

[2] | Motor cable |

[3] | Ground strap (HF litz wire) |