Configuration

- For the following application example, a MOVI-C® CONTROLLER is required as hardware. The real axes used are simulated.

- In MOVISUITE® in "Planning" mode, create a project with a MOVI-C® CONTROLLER, one virtual axis ("master") and one real axis ("FlyingSaw"). In the application example, the virtual axis acts as the master axis.

- Configure a valid drive train without user units for the real axis.

- Assign the following software modules to the axes:

- Configure the user unit for the "master" axis:

- Configure the user unit for the "FlyingSaw" axis:

- Configure the software module of the "master" axis:

- Configure the software module of the "FlyingSaw" axis:

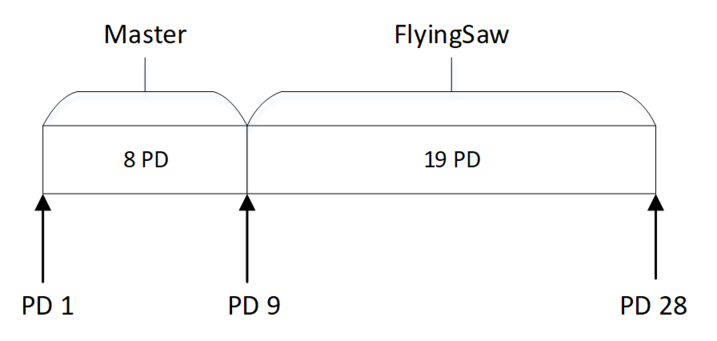

- The configuration results in the following process data assignment:

- Open the configuration of the MOVIRUN® flexible.

- Select a fieldbus protocol in the "Fieldbus" configuration menu in the "Fieldbus card" section.

- Switch to "Startup" mode.

- Connect the MOVI-C® CONTROLLER in the project view with the MOVI-C® CONTROLLER in the network view and then update the IEC project.