Print mark recognition

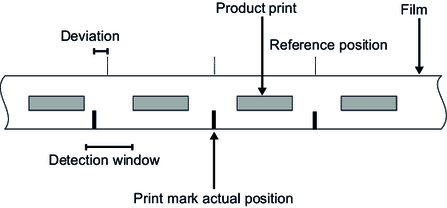

The additional "Print mark recognition" function makes possible a constant print pattern despite the film being stretched or compressed by the process or compensation for a film feeder that is slipping. The print mark recognition is configured using the "Reference print mark", "Proportional factor" and "Integrative factor" parameters.

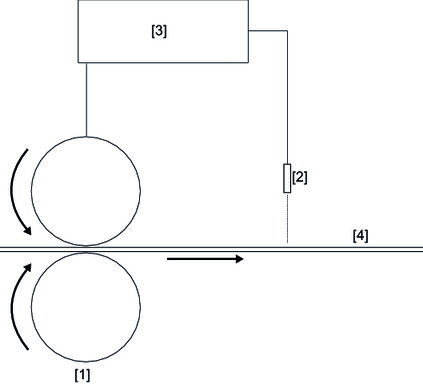

A print mark sensor, connected to the motion control system, is needed for print mark recognition. The following diagram contains an example of how the components involved could be arranged.

[1] | FilmFeeder axis | [3] | Motion control system |

[2] | Print mark sensor | [4] | Film with print marks |

Operating principle

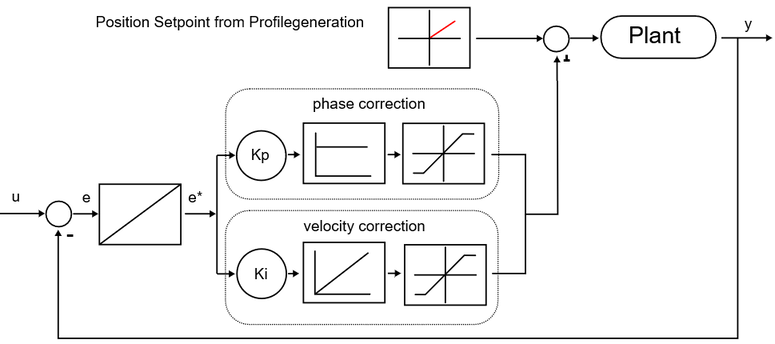

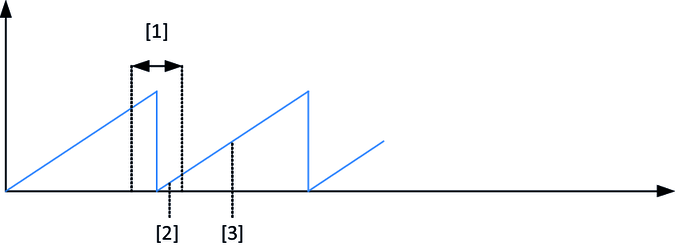

The "Print mark controller" function impacts on the setpoint profile of profile generation. The measured print mark error "e" results from the difference between the target print mark position "u" and the actual print mark position "y". The print mark error is converted into a modulo value "e*". This value is weighted with the adjustable factors "Kp" and "Ki". A limitation can be activated for the proportional phase correction. The integrative speed correction is always limited to +-20% of the target feed.