Dead time compensation of the actuator

The dead time of the actuator in relation to the position can be compensated for in terms of speed and acceleration.

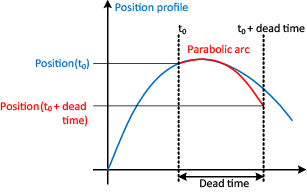

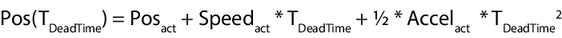

The state of the output is determined based on the assumption that the acceleration does not change during the dead time. The position reached after the dead time has elapsed is therefore calculated in advance based on the current position, the current speed, and the current acceleration.

Descriptively, this means: The position profile is extrapolated at each point by a parabolic arc with the same slope (velocity) and the same curvature (acceleration). Based on this parabolic arc, the position is calculated after the dead time has elapsed. Significant deviations occur when the acceleration changes significantly within the dead time.

INFORMATION

For example, if the setpoints of an axis are used as the source and the axis is moved without jerk limitation, the acceleration may change abruptly. In unfavorable cases, this can cause a cam output to bounce. If this occurs, proceed as follows:

- Disable acceleration compensation.

- Configure a jerk ≠ 0 so that a sudden change in acceleration is excluded.

- Configure a hysteresis.

|

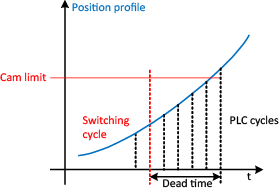

The cam switches to the PLC cycle in which the extrapolated position has exceeded the cam limit.

|