Requirements for the operation of the STO safety sub-function

- Operation is only permitted within the limits specified on the data sheets. This applies to an external safety controller, an external safety relay, as well as to the device and the approved safety options.

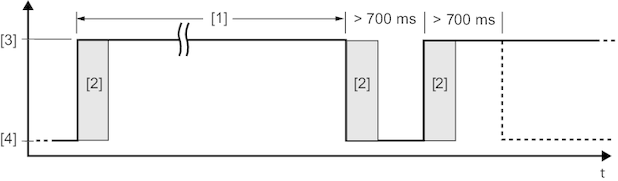

- The built-in diagnostic function is limited in the case of a permanently enabled or permanently disabled STO input. Advanced diagnostic functions are performed only upon a level change of the STO signal. The safety sub-function must therefore be requested via the STO input for PL d in accordance with EN ISO 13849-1 and SIL 2 in accordance with EN 61800-5-2 at least once every 12 months, and for PL e in accordance with EN ISO 13849-1 and SIL 3 in accordance with EN 61800-5-2 at least once every 3 months with the line voltage applied in order to achieve full test coverage. Adhere to the following test procedure for this purpose.

[1]

Maximum 12 months for PL d/SIL 2

Maximum 3 months for PL e/SIL 3

[2]

Internal diagnostics

[3]

High: No STO

[4]

Low: STO active

- To achieve complete test coverage after a device reset (e.g. after switching on the supply voltage), the test transition (STO active → STO not active) may be started after > 700 ms at the earliest. The device signals the "ready for operation" or "STO – Safe Torque Off" state if it is not in fault state.

- A detected hardware fault in the internal switch-off channels for STO will lead to a locking fault state in the device. If the fault is reset (e.g. by switching the supply voltage on/off or by a low level at the STO input for at least 30 ms), a complete test with internal diagnostics according to the above-mentioned test procedure must be performed. If the fault occurs again, replace the device or contact SEW‑EURODRIVE Service.