Tower sway

- Define the "Distance between lifting and traveling trolley" (the sway should be suppressed at this lifting height) by configuring the "Source of distance between lifting and traveling trolley".

- Configuration value: Use the value specified manually in the "Distance between lifting and traveling trolley" setting field in the "Basic settings" section.

- Configured axis: Use the position of a configured axis such as the lifting axis as a value. Thus, the sway suppression is always suitable for the lifting height or the distance between the lifting and traveling trolley. To do so, select and configure the axis using the displayed setting fields. A "Lifting position offset" can be used here to calculate the compensation if the value from the axis does not match the actual distance between lifting and traveling trolley. You can also select the user unit of the lifting axis or enter a user-defined conversion factor for the user unit in meters.

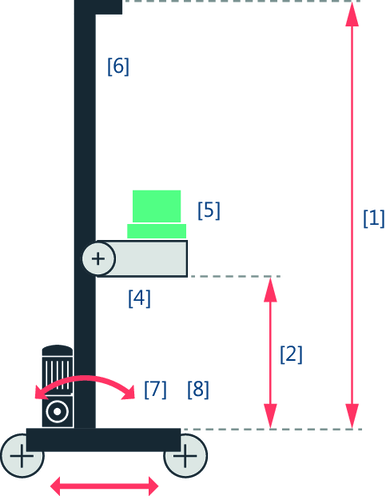

- Configure the mechanical parameters of the application in the "Basic settings" section. The following diagram shows the parameters available for this application type. For detailed descriptions of the parameters, refer to chapter Anti-sway control. If you do not already know the "Spring stiffness between tower and traveling trolley" and the "Damping ratio between tower and traveling trolley", e.g. from mechanical simulations, you can apply the suggested values calculated from the previously configured mechanical parameters or activate Support for parameter determination ("From measurement") here.

[1] | Height of the tower |

[2] | Distance between lifting and traveling trolley |

[4] | Mass of the lifting trolley |

[5] | Mass of the payload |

[6] | Mass of the tower |

[7] | Spring stiffness between tower and traveling trolley INFORMATION: To determine this parameter, see chapter Determining stiffness. |

[8] | Damping ratio between tower and traveling trolley INFORMATION: To determine this parameter, see chapter Determining stiffness. |

- Define the time window by configuring the "Ramp time tension build-up" and the "Jerk time tension build-up" in the "Time window" section. These parameters define the respective duration of the mechanical tension build-up. For longer times, more time is used for sway suppression and thus the dynamics of the correction signal is reduced. The positioning process is extended by these times. However, the jerk time of the travel axis can be reduced at the same time. A value is suggested for both parameters that you can adopt and adjust if necessary. The "Cycle time of the HighPrio task for limit value calculation" is also shown in this section. The displayed value is taken from the "Setpoint cycle control" parameter of the lower-level member.