Activation of the function

WARNING

Danger from falling loads.

Severe or fatal injuries.

- Do not use the "Release brake/deactivate DynaStop® for FCB01" function for hoists or applications with potentially falling loads.

- Inhibit the function via the following steps:

- Deactivate the function of DIP switch S1/2 via parameter Functions > Inputs/outputs > Basic device > DIP switch functions > Release brake/deactivate DynaStop® for FCB01 – enable > "Deactivation" = "1".

- Disable the function via parameter Functions > Drive functions > FCB01 Output stage inhibit > "Release brake/deactivate DynaStop® for FCB01 – enable" = "0".

In case the output stage is inhibited by a control signal (digital input or process data bit), you can release the brake/deactivate DynaStop® by using the "Release brake/deactivate DynaStop® with FCB 01" function. For example, this allows to move loads freely using a horizontal conveyor.

Now make the following settings:

- Enabling the function:

- Via DIP switch S1/2

Switch DIP switch S1/2 "Release brake/deactivate DynaStop® for FCB01 – enable" = ON. - Via parameter setting

Make sure that DIP switch S1/2 has been deactivated via parameter Functions > Inputs/outputs > Basic device > DIP switch functions > Release brake / deactivate DynaStop® for FCB01 enable > "Deactivation" = "1".

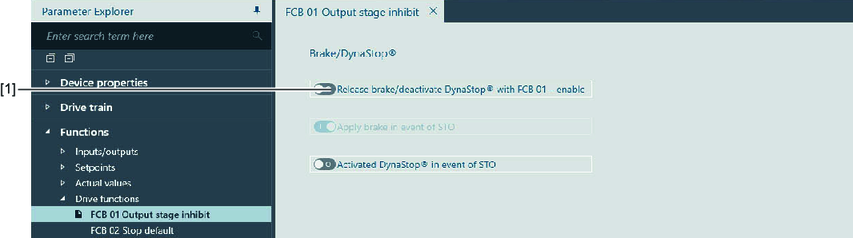

Enable the function via parameter Functions > Drive functions > FCB01 Output stage inhibit > "Release brake/deactivate DynaStop® with FBC 01- enable" = "1" [1]. - Configuring the control signal:

- Control via digital input

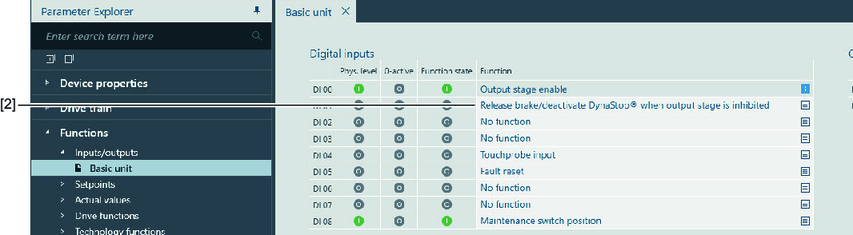

Assign a digital input via the function "Release brake/deactivate DynaStop® when output stage is inhibited" [2]. - Control via process data bit (not available with DBC designs)

Use the "Release brake" control bit of the MOVIKIT® control word to release the brake/deactivate DynaStop® for FCB01.

For further information, refer to the corresponding MOVIKIT® documentation.