Selecting the MOVIMOT® performance drive unit

Observe the following points when selecting the MOVIMOT® performance drive unit:

- Selection of a suitable gear unit size

(Specification: Helical-bevel gear unit) - Requirement: The maximum output torque of the gear unit must be greater than the maximum required application torque: Ma max ≥ Mmax.

- On the basis of the application calculations and taking account of the efficiency, the maximum application torque during startup (first travel section) is Mmax = 145 Nm

- Result: Helical-bevel gear units of size K.37 meet this requirement.

- Selecting the gear ratio with suitable output speed:

- Requirement: The application calculations result in a maximum required output speed of nmax = 50 min-1.

- To achieve a high setting range and an optimum efficiency, the required output speed should be achieved as precisely as possible at an input speed of ne = nN = 2000 min-1 (nominal motor speed).

- Result: As there is no ideal gear ratio

for the selected gear unit, the next smaller gear ratio available i = 37.97 is selected. - There are no external overhung loads acting on the gear shaft in this example.

- Choosing the right motor:

- Requirement: Select a motor/inverter combination that can provide at least

at peak performance.

at peak performance. - Result: In the following table, select motor CM3C80S/D.. with the assigned 2.0 A inverter.

MOVIMOT® performance | CM3C.. | |||||||

|---|---|---|---|---|---|---|---|---|

80S/D.. | 80S/D.. | 80S/D.. | 80S/D.. | 80M/D.. | 80M/D.. | |||

Size of electronics cover | Size 1 | Size 1 | ||||||

Electronics cover (inverter) | 0020 | 0025 | 0032 | 0040 | 0040 | 0055 | ||

Nominal output current of the electronics cover (inverter) | IN_ | 2.0 A | 2.5 A | 3.2 A | 4.0 A | 4.0 A | 5.5 A | |

Nominal power | PN | 0.754 kW | 0.942 kW | 1.19 kW | 1.51 kW | 1.68 kW | 1.88 kW | |

Nominal torque | MN | 3.6 Nm | 4.5 Nm | 5.7 Nm | 7.2 Nm | 8 Nm | 9 Nm | |

Overload capacity of MN |

| 300% | 300% | 300% | 300% | 300% | 300% | |

- Checking further topics:

- Feasibility of the selected motor/gear unit combination

- Checking the setting range:

- Setting range of the application

- This means the speed setting range of 1:40 is sufficient. The encoder option needs not be selected. na at ne = 50 min-1

- Thermal check of the MOVIMOT® performance drive unit

- Requirement: In order to avoid thermal problems, the effective torque requirement of the application must be smaller than the continuous output torque of the MOVIMOT® performance drive unit.

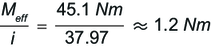

- The effective torque requirement (including the efficiency of the application) is 45.1 Nm, which corresponds to a torque requirement of

at the motor shaft.

at the motor shaft. - The selected motor/inverter combination CM3C80S/D.. with the assigned inverter 2.0 A has a nominal torque of 3.6 Nm.

- Result: The requirements are met.

- Checking further topics:

- Derating due to increased ambient temperature

- Derating due to installation altitude

- Checking the braking resistor

- Calculation of the regenerative power when decelerating:

- The remainder of the check takes place in accordance with chapter Regenerative current-carrying capacity of the integrated braking resistor.