Operating modes

INFORMATION

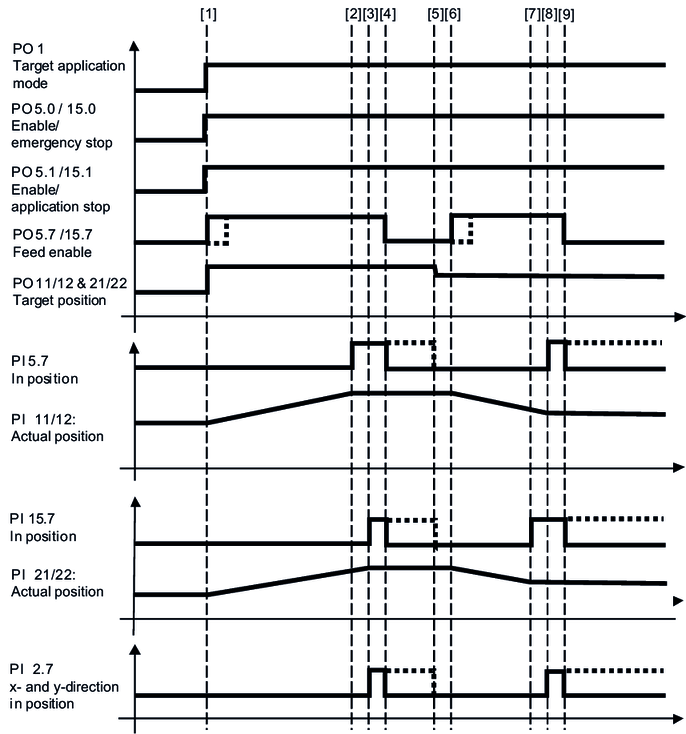

A requirement for all operating modes is that the axes are enabled via the enable bits Enable/emergency stop and Enable/stop at user-defined limits in the control word. For more information, refer to the chapters MOVIKIT® StackerCrane control word and Process data assignment.

The operating mode is defined via process data word for all lower-level axes of the software module. The operating mode is changed over in idle state.

The software module provides the following operating modes:

Operating mode | Dec | Description |

|---|---|---|

Default | 0 | Enabling or disabling the axes |

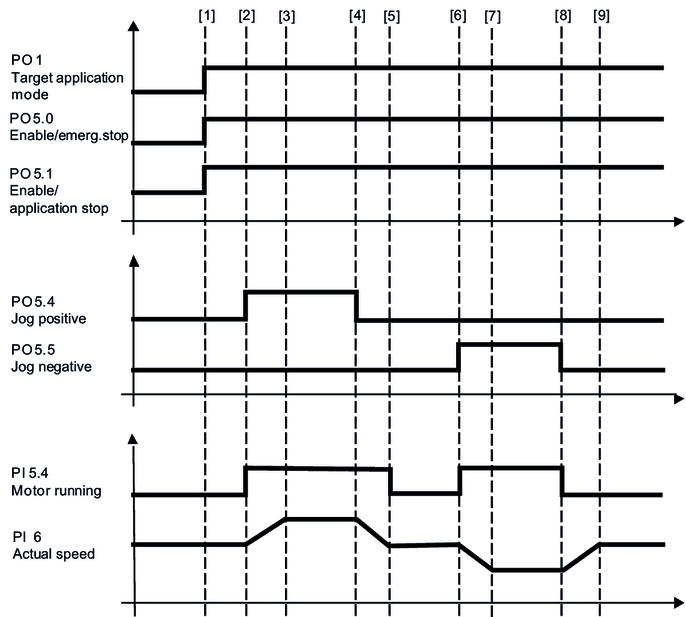

Jog mode | 100 | The axes are moved manually using the bits jog positive, jog negative, and the corresponding dynamics parameters. |

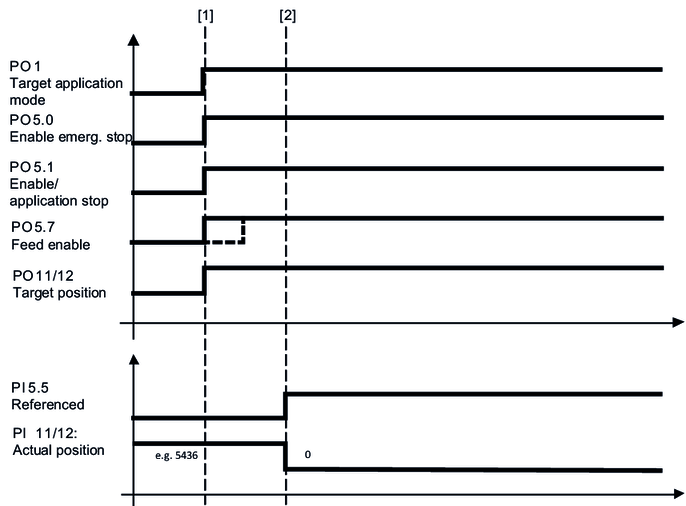

Referencing mode | 300 | A configured reference offset is written to the actual position |

301 | A reference offset specified via bus is written to the actual position | |

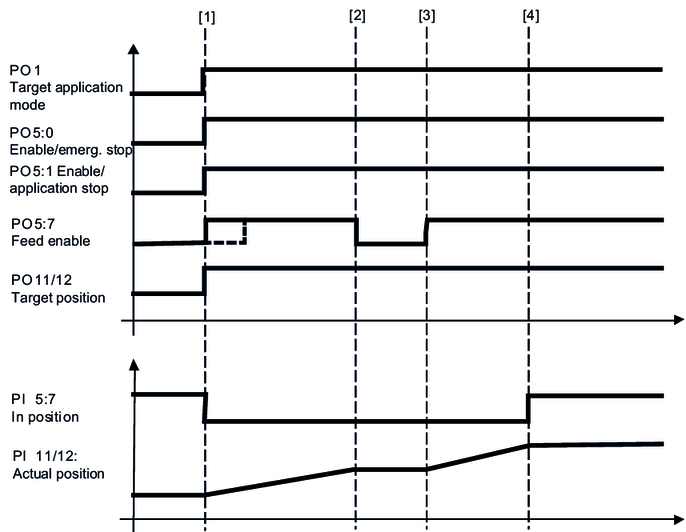

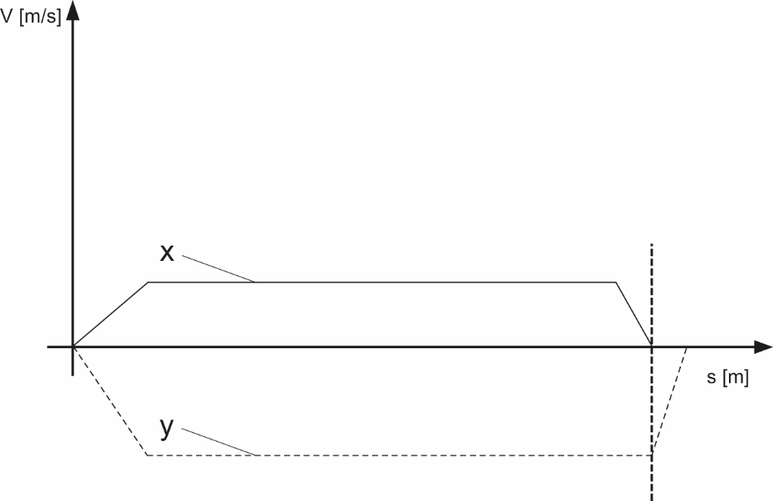

Positioning mode | 400 | Positioning of the axes is not energy optimized |

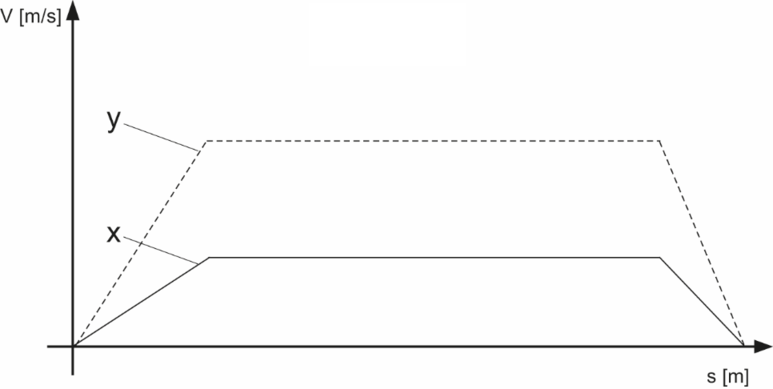

Energy-optimized XY positioning | 1200 | Energy-optimized positioning of the axes |

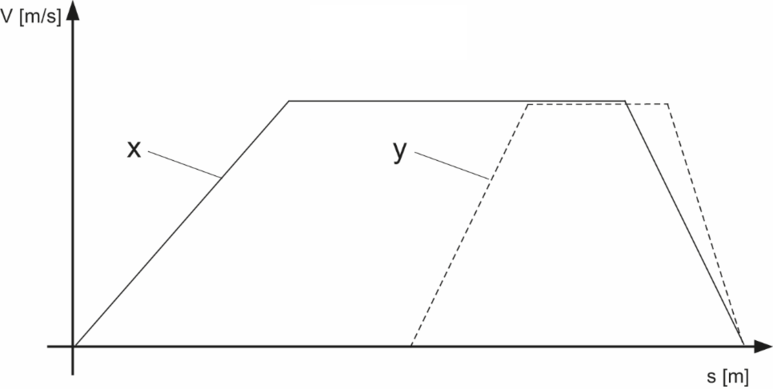

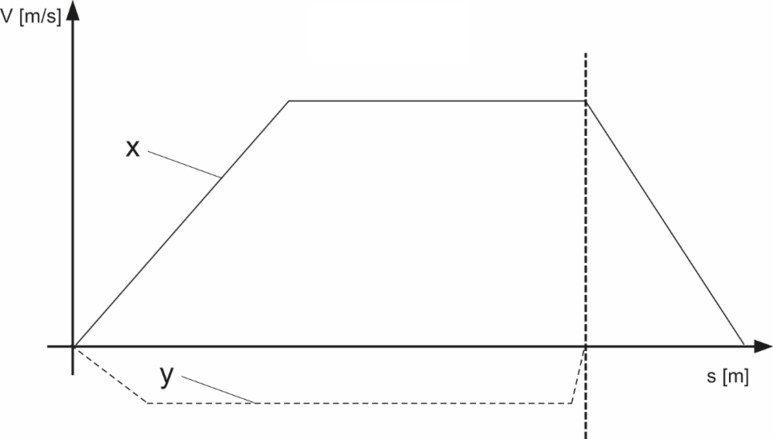

Mechanics-optimized positioning | 1210 | Diagonal positioning by reducing the speed of an axis. |

External brake test | 1300 | Preparing the external brake test The brake test is configured via safety card and is controlled using the safe bus or safe inputs. |

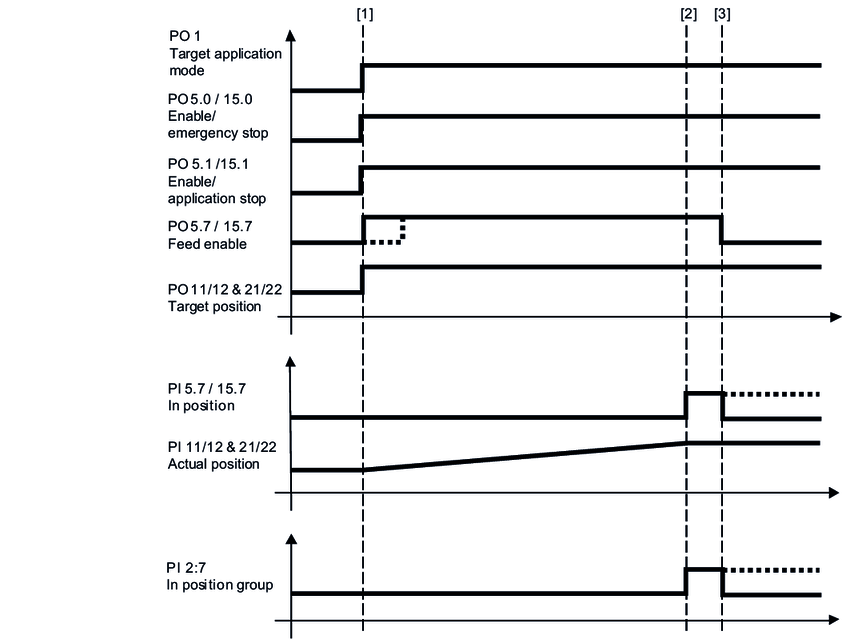

The following chapters provide a cycle diagram for each operating mode to help you better understand the operating principle. They also provide a process sequence with a description of the signals to be set and of the signal states.