Torque > 0

The following application example shows how to control the "Torque control" operating mode in the IEC program.

Control

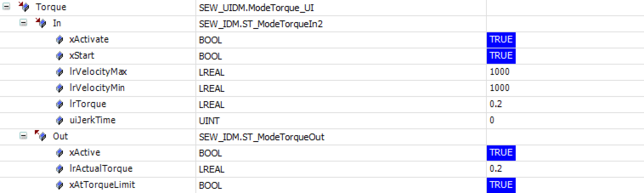

Control the axis in the Torque structure as follows:

- To activate the operating mode, set xActivate to "TRUE".

- Define the setpoints for lrVelocityMax, lrVelocityMin, and lrTorque.

- To start the operating mode, set xStart to "TRUE".

Interface in the IEC Editor

Note:

When the setpoint torque is reached, you will receive the feedback xAtTorqueLimit = "TRUE" in the OUT structure.

Trace recording

The following trace recording shows the profile of the current speed and the current torque with the values set at start as described above. The current torque is set immediately to the required torque when starting. The xAtTorqueLimit feedback is "TRUE". The axis accelerates with the torque in positive direction. When the maximum speed is reached, the current torque is reduced and the xAtTorqueLimit feedback is set to "FALSE".

[1] | Torque.In.xActivate |

[2] | Torque.In.xStart |

[3] | Torque.In.lrVelocityMax |

[4] | Torque.In.lrTorque |

[5] | Torque.In.xAtTorqueLimit |

In the following trace recording, the axis is first held at standstill by the load; the current speed is zero and the xAtTorqueLimit feedback is "TRUE". Then the load suddenly disappears and the axis accelerates in positive direction. The current torque is reduced as soon as the maximum speed is reached. The xAtTorqueLimit feedback is accordingly set to "FALSE".

[1] | Torque.In.xActivate |

[2] | Torque.In.xStart |

[3] | Torque.In.lrVelocityMax |

[4] | Torque.In.lrTorque |

[5] | Torque.In.xAtTorqueLimit |

Note:

The scenario under consideration here occurs, for example, in the case of material tearing in a winder operated in torque control mode. It is important that the axis speed does not exceed the lrVelocityMax limit.